Three-jaw expansion floating pressure head

A technology of floating indenter and indenter, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems of difficulty in ensuring the accuracy of press fitting, low efficiency of manual installation, and high labor intensity, etc., and achieves the effect of convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

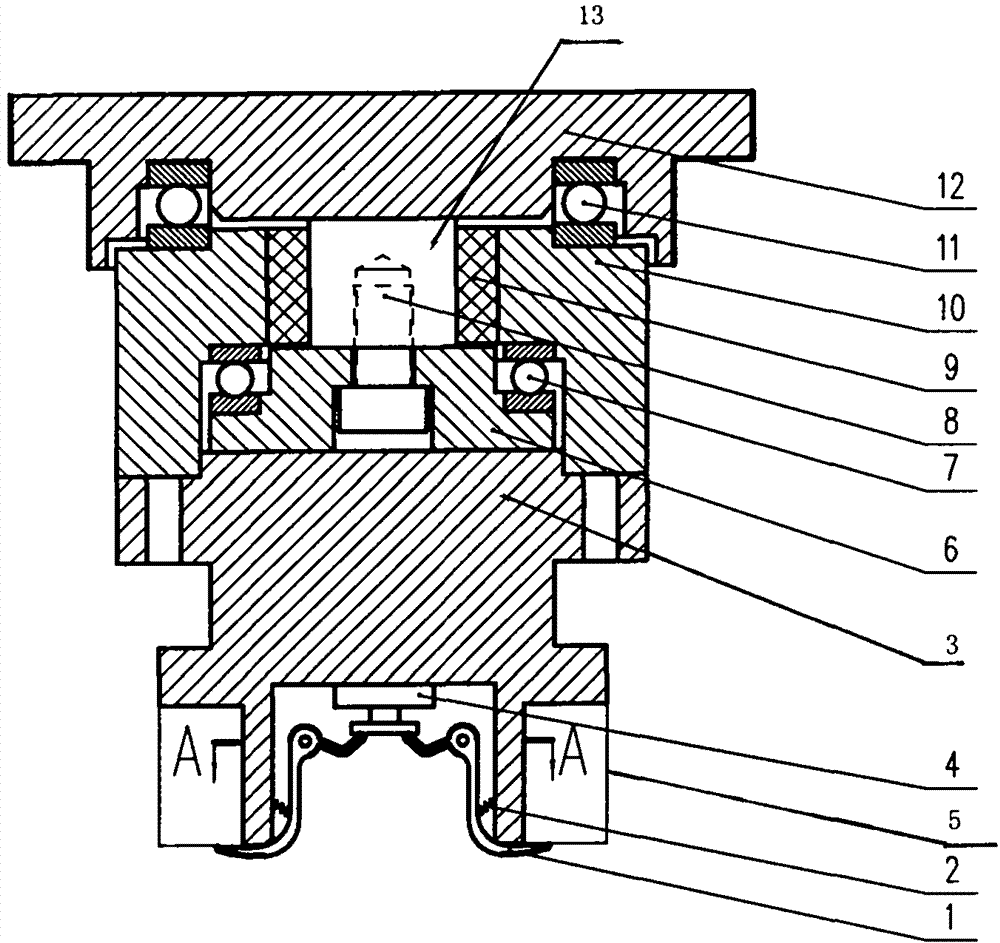

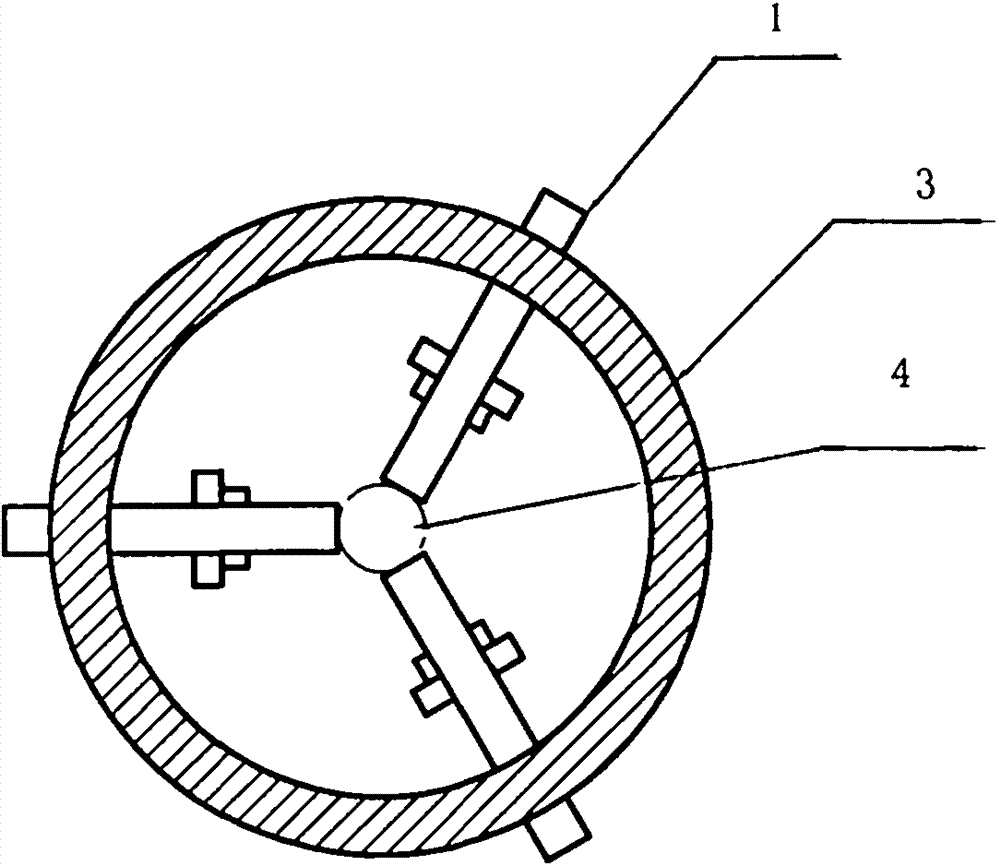

[0013] like figure 1 , figure 2 As shown, the three-jaw telescopic floating pressure head is mainly composed of two parts: a three-jaw telescopic hook device and a floating deviation correction device. The three-jaw telescopic hook device is composed of a three-jaw telescopic hook 1, a spring 2, a pressure head body 3, and an electromagnet push rod 4; the floating deviation correction device is composed of a support plate 6, a ball 7, a screw 8, and a rubber elastic ring 9 , Lower supporting seat 10, ball two 11, upper supporting seat 12 form.

[0014] Upper support seat 12 is connected as a whole with connecting shaft 13, also can be that lower support seat 10 is connected as a whole with connecting shaft 13, rolling body ball 2 11 is housed between upper support seat 12 and lower support seat 10, and lower support seat 10 There is a rolling ball 7 between the supporting disc 6 and a rubber elastic ring 9 between the lower supporting seat 10 and the upper supporting seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com