Laminated film and adhesive tape

A technology of laminated film and adhesive tape, which is applied in the direction of film/sheet adhesives, adhesives, adhesive products, etc., and can solve the problems of difficult prism sheet appearance inspection and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

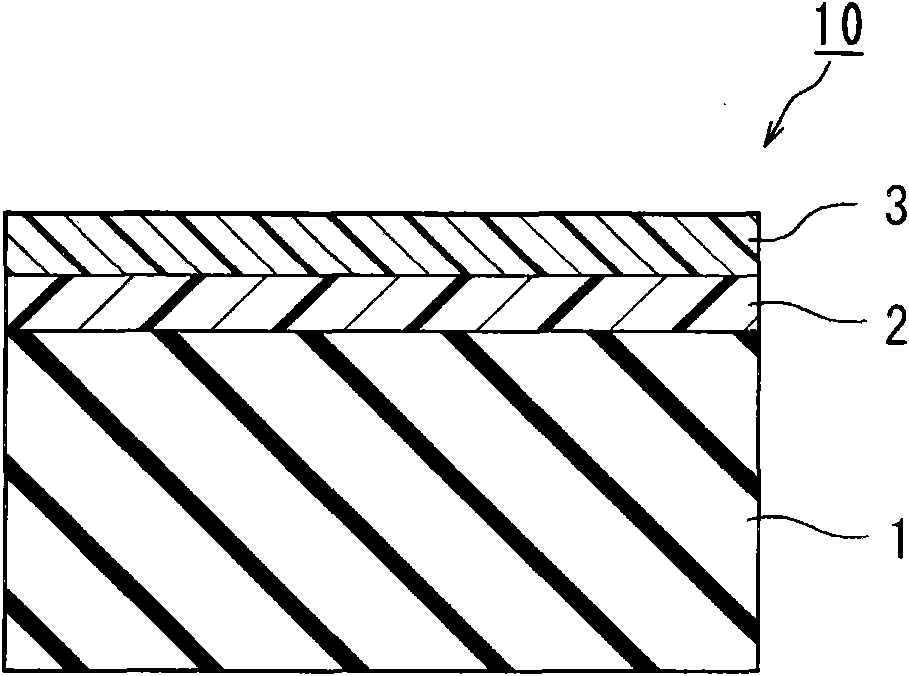

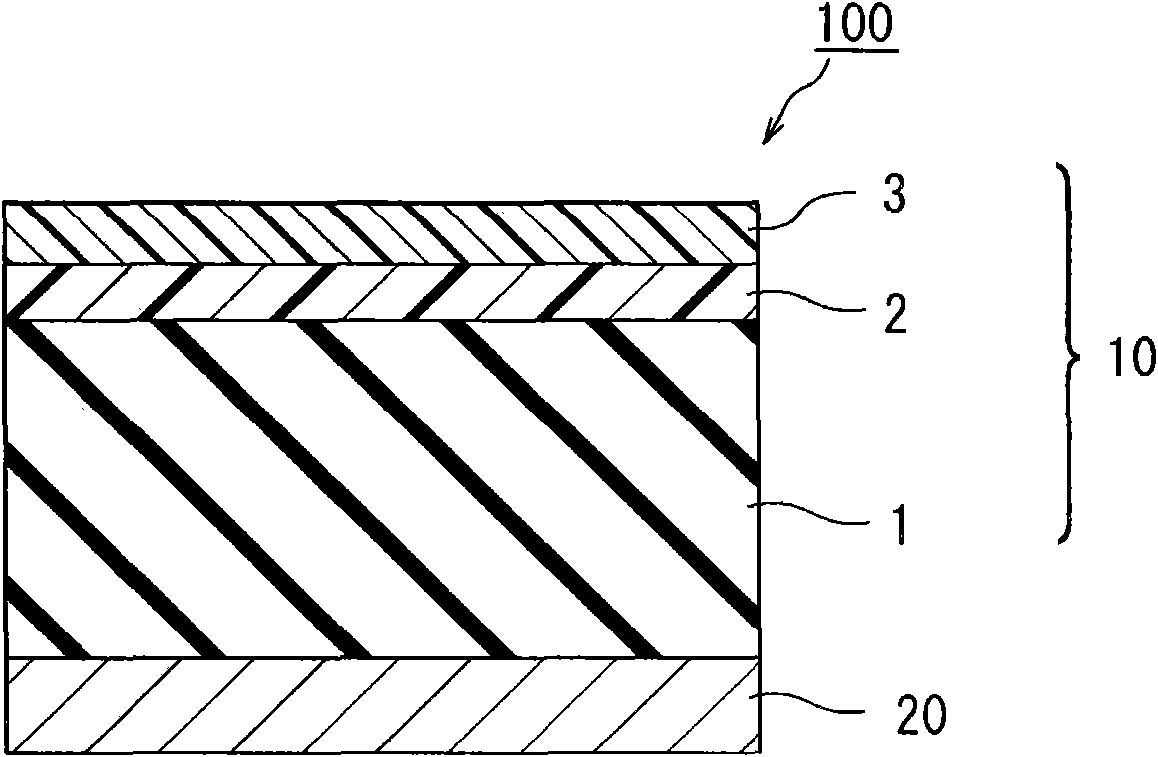

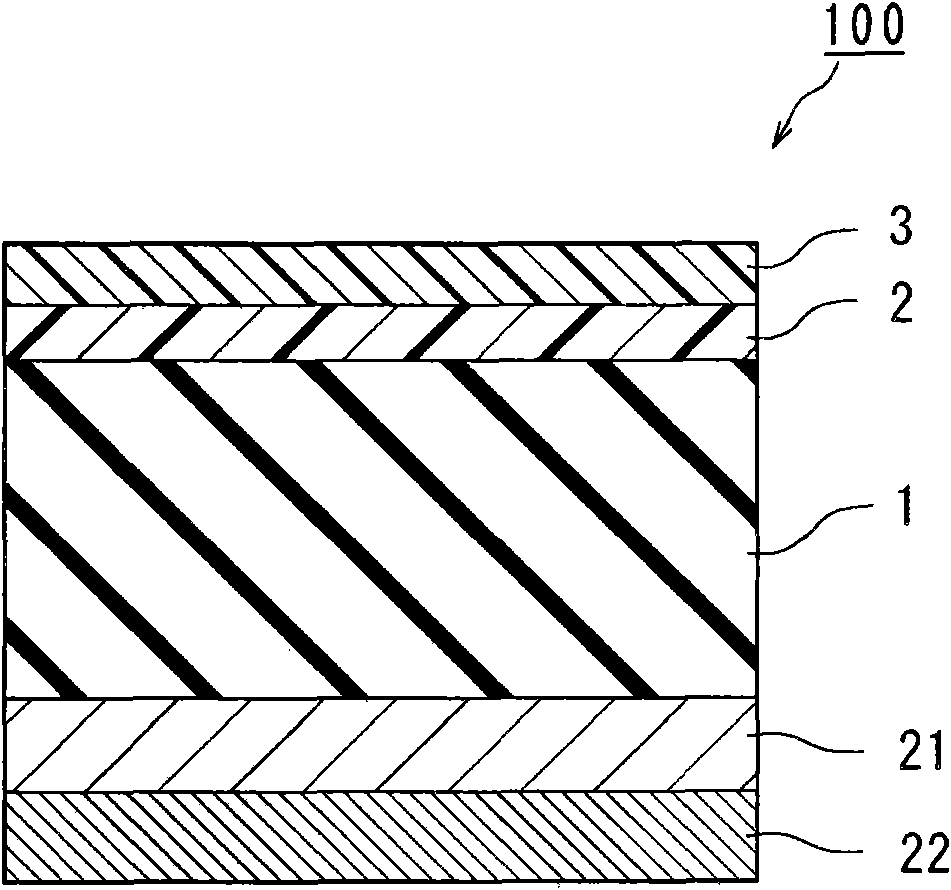

[0184] The following compounds were prepared as the roughness expressing layer forming material, the fine unevenness eliminating layer forming material, the substrate layer forming material and the smooth layer forming material.

[0185] Rough surface layer forming material: 75 parts of リアクタ-TPO (manufactured by SunAllomer Co., Ltd.: キヤタロイ Q300F; melt flow rate (MFR) = 0.8 (230° C., 2.16 kgf)) and polypropylene obtained using a metallocene catalyst (Japanese polypropylene Co., Ltd.: Wintec WFX4; Melt flow rate (MFR) = 7.0 (230°C, 2.16kgf)) mixture of 25 parts

[0186] Forming material of fine unevenness eliminating layer: low-density polyethylene (manufactured by Nippon Polyethylene Co., Ltd.: ノバテック LD LC720; melt flow rate (MFR) = 9.4 (190° C., 2.16 kgf))

[0187] Substrate layer forming material: Block polypropylene (manufactured by SunAllomer: PF380A)

[0188] Smooth layer forming material: low-density polyethylene (manufactured by Nippon Polyethylene Co., Ltd.: Nobatec LD...

Embodiment 2

[0191] A laminated film (2) was obtained in the same manner as in Example 1 except that the thickness of the rough surface layer was set to 5 μm. The thickness of the fine unevenness eliminating layer was 2 μm, the thickness of the rough surface layer was 5 μm, the thickness of the substrate layer was 38 μm, and the thickness of the smooth layer was 7 μm. Table 1 shows the evaluation results of the obtained laminated film (2).

Embodiment 3

[0193] A laminated film (3) was obtained in the same manner as in Example 1 except that the thickness of the rough surface layer was set to 10 μm. The fine unevenness eliminating layer had a thickness of 2 μm, the rough surface layer had a thickness of 10 μm, the substrate layer had a thickness of 38 μm, and the smooth layer had a thickness of 7 μm. Table 1 shows the evaluation results of the obtained laminated film (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap