Methods and apparatus for initiating scoring

A technology of equipment and mechanical scribing, applied in welding equipment, glass manufacturing equipment, laser welding equipment, etc., can solve problems such as expensive and complex equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

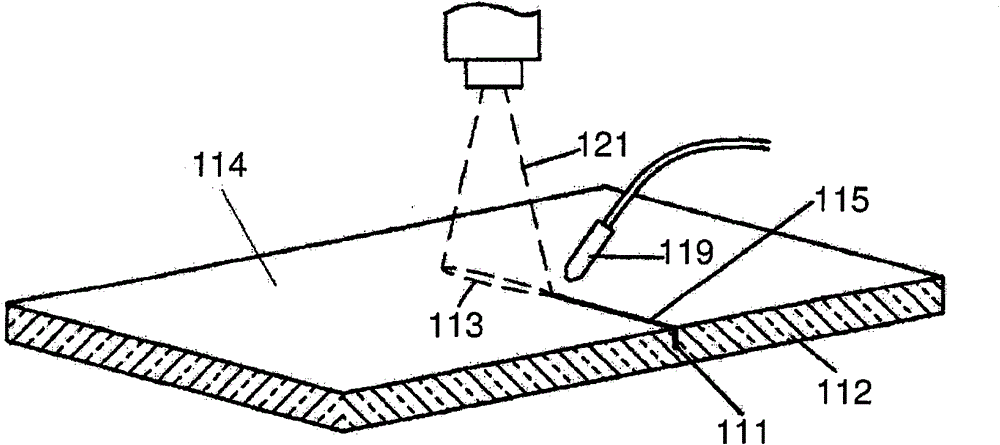

[0076] As noted above, in an exemplary embodiment, the present invention is directed to an apparatus and method for initiating cracks in a moving glass ribbon using a mechanical scoring device. Mechanical scoring devices can have various configurations and structures now known or later developed. Regardless of configuration, the mechanical scoring apparatus will include a mechanical scoring head that contacts the surface of the glass ribbon and forms the initial crack. A representative structure may include an indentation or scoring wheel made of tungsten carbide or diamond attached to a mechanism such as an air cylinder for maintaining a substantially constant pressure on the glass surface. The scoring force of , regardless of the variation in the position of the surface, for example along the direction perpendicular to the nominal plane of the glass surface.

[0077] Because glass ribbons can be very thin and flexible, for example glass ribbons used to produce substrates fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com