Foam\water mixing balanced valve

A balance valve, horizontal technology, applied in the direction of balance valve, valve detail, multi-way valve, etc., can solve the problems of narrow adjustment range and poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

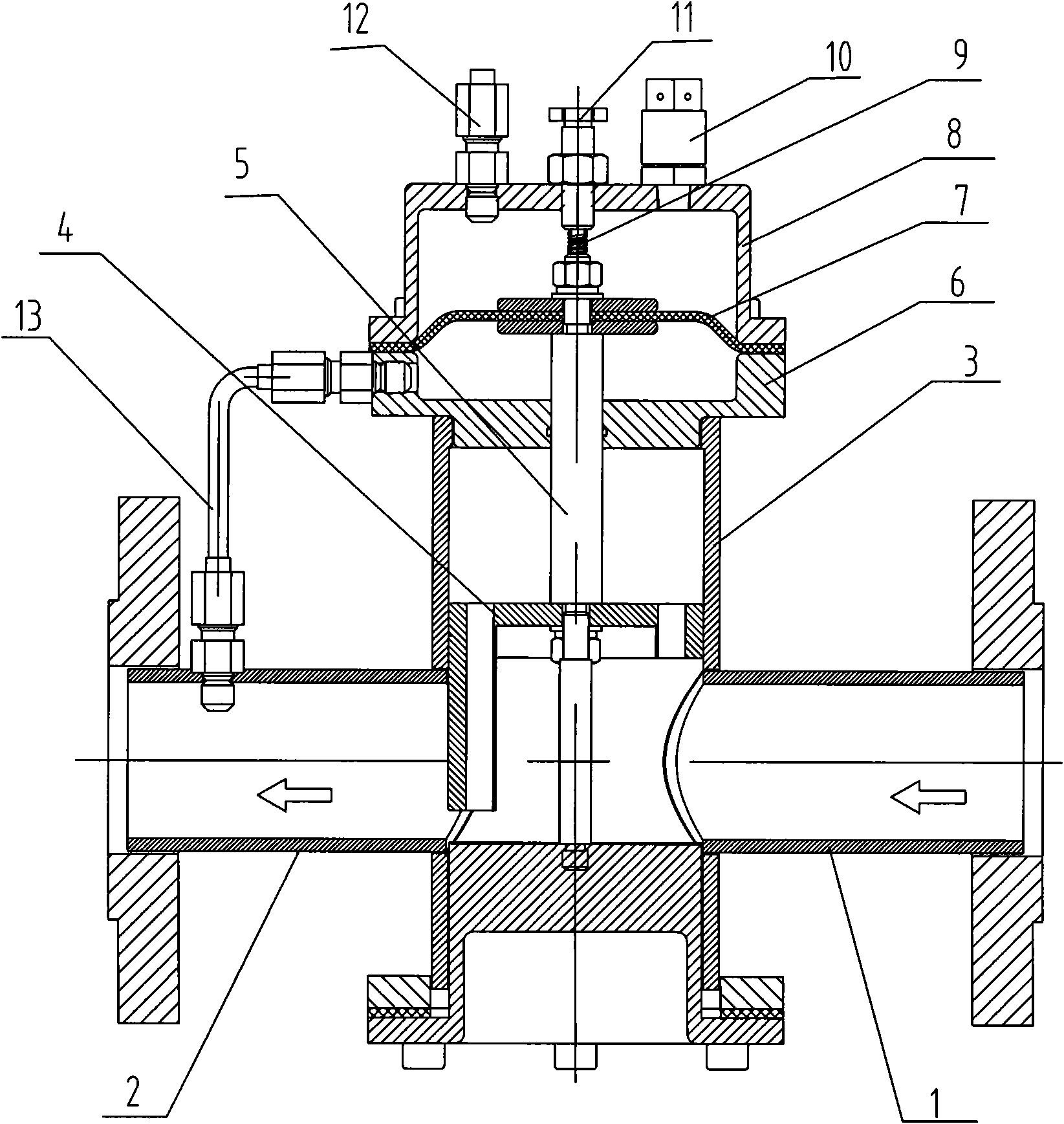

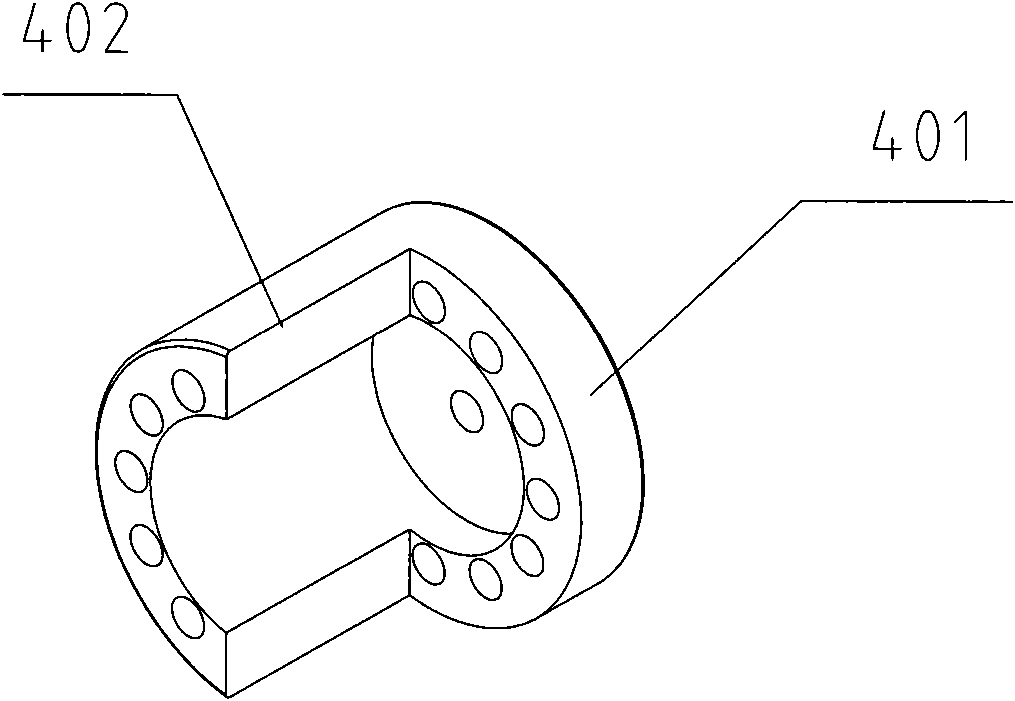

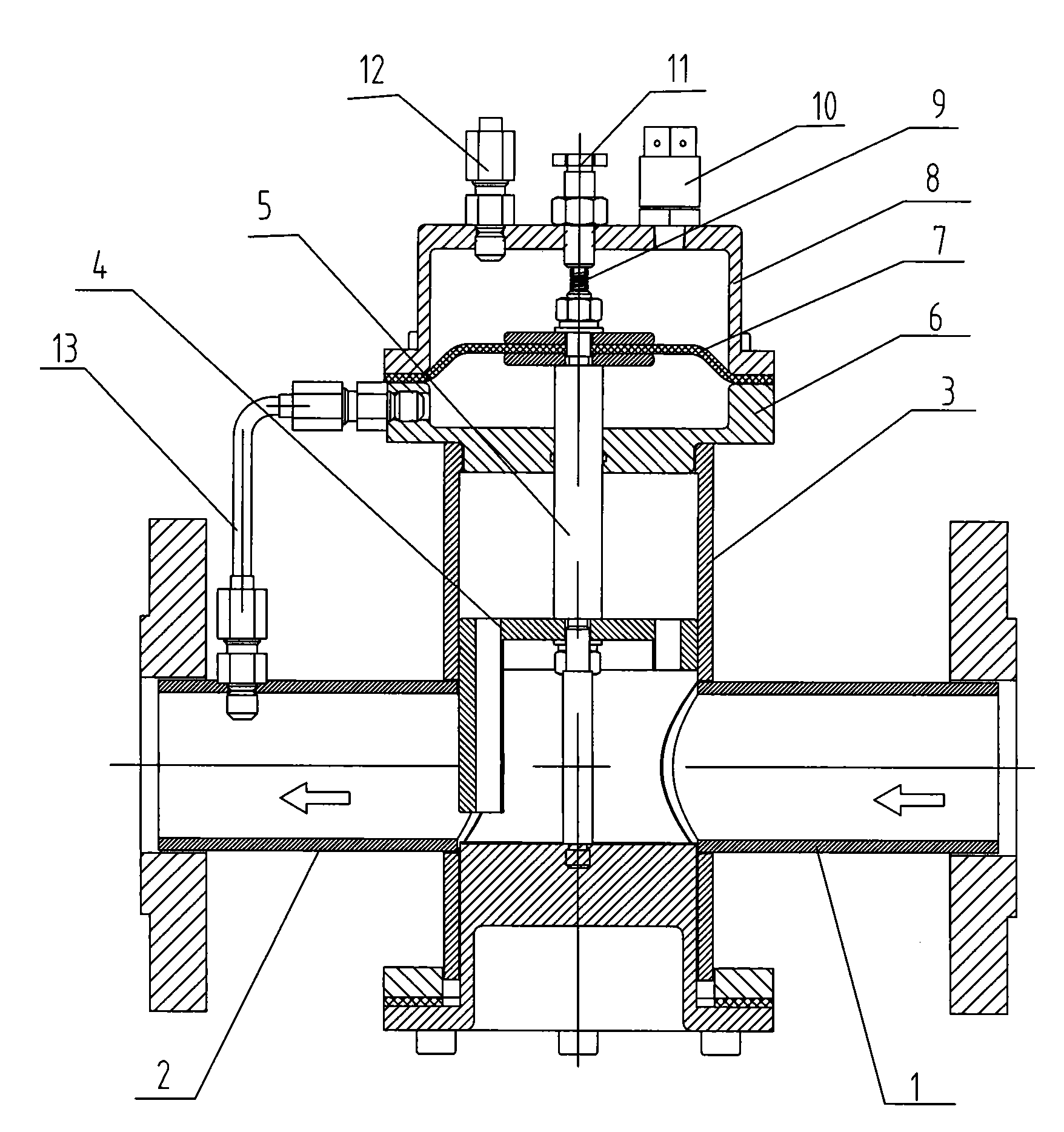

[0015] refer to figure 1 , figure 2 , a foam / water mixing balance valve of the present invention mainly includes a valve body, a valve core 4, a valve stem 5 and a balance cavity. Wherein, the valve body is a typical three-way valve body, which has a horizontal inlet pipe 1, a horizontal outlet pipe 2 and a vertical pipe 3, and a valve core 4 and a valve stem 5 for fixing the valve core 4 are arranged in the vertical pipe 3, and the valve core 4 includes a vertically connected flashboard 402 and a piston 401, the flashboard 402 is close to the horizontal outlet pipe 2, and the piston 401 is in sliding fit with the vertical pipe 3. Fill the foam liquid into the horizontal inlet pipe 1, the piston 401 moves the valve stem 5 upward under the pressure of the foam liquid, and opens the gate 402, and when the gate 402 is opened, the pressure of the piston 401 decreases, and the gate 402 opens again. There is an adjustment tendency for the opening to decrease, therefore, the spool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com