Surface mounting metal elastic sheet with bending enhancement part on spring arm

A metal shrapnel, surface-mounted technology, applied in the direction of clamping/spring connection, etc., can solve the problem of easy breakage, avoid easy deformation, reduce the probability of failure, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

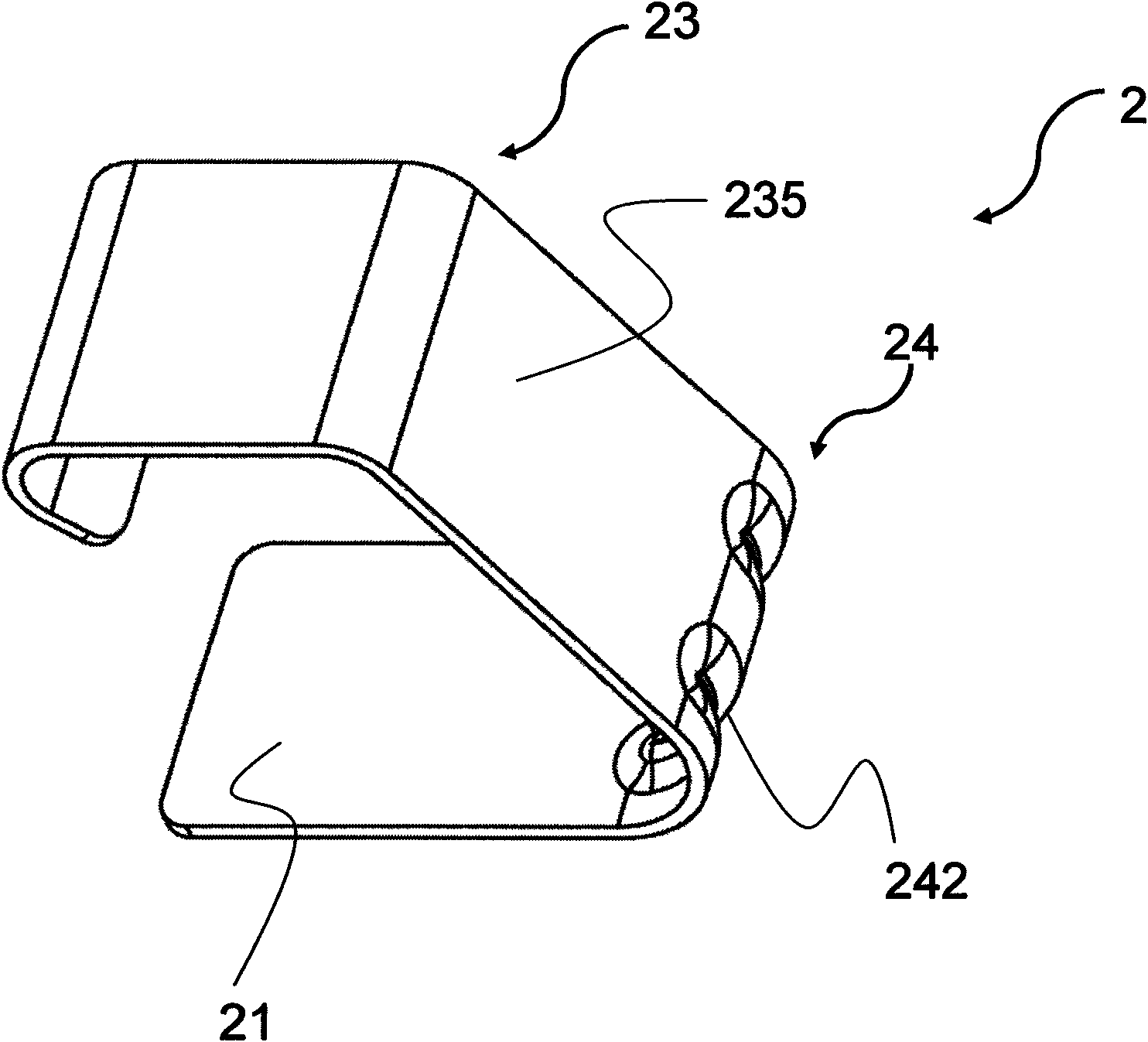

[0033] The invention can be used to electrically connect a substrate and other matching components, and can be used for electromagnetic protection. The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with accompanying drawings. And for the sake of explanation, in addition to the installation section of the following shrapnel for welding to the circuit board, various complex deformations above the installation section are called elastic arm sections. As for the differences between the elastic arm sections of various shrapnel, in this The inventions are not listed one by one.

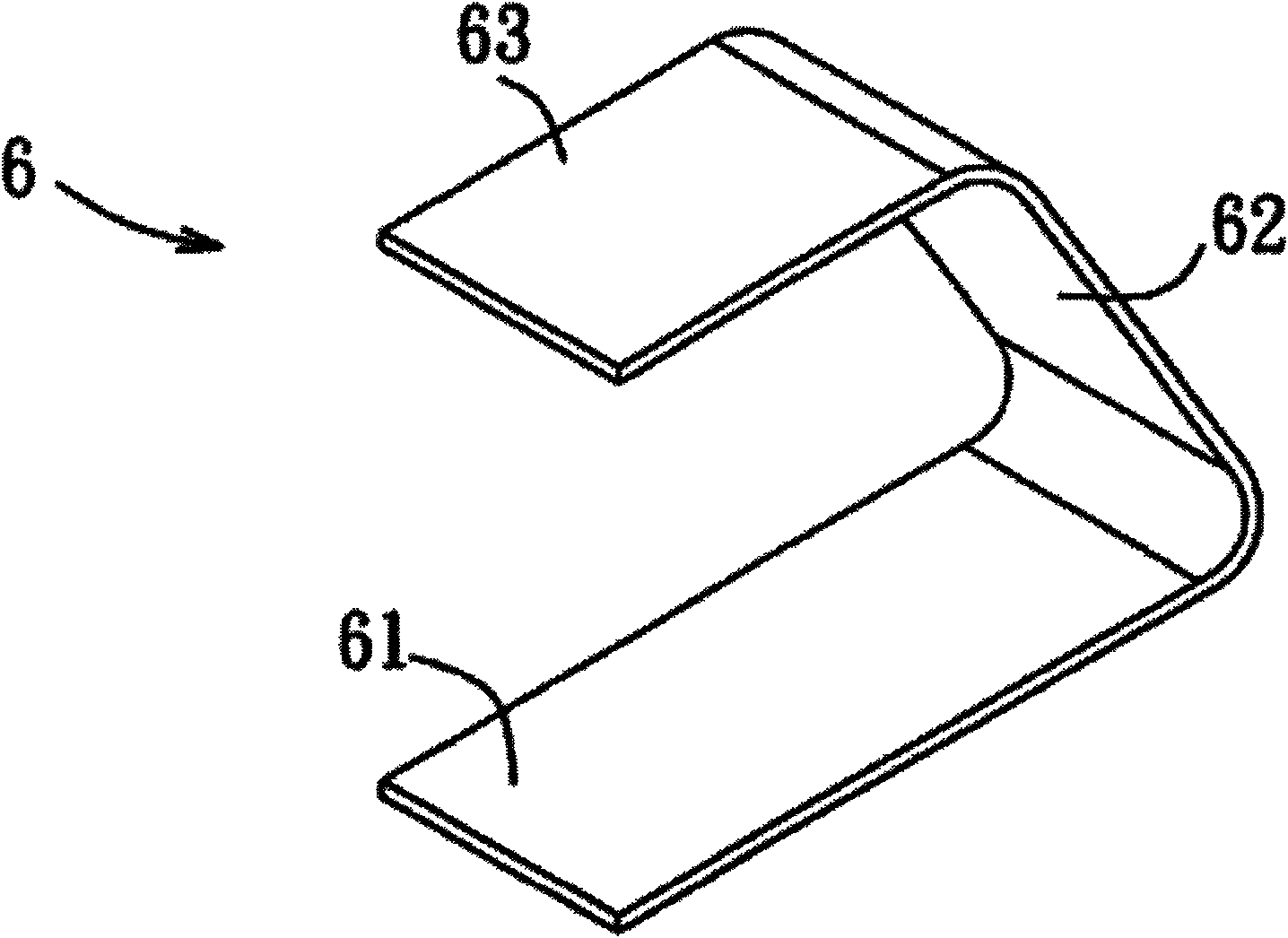

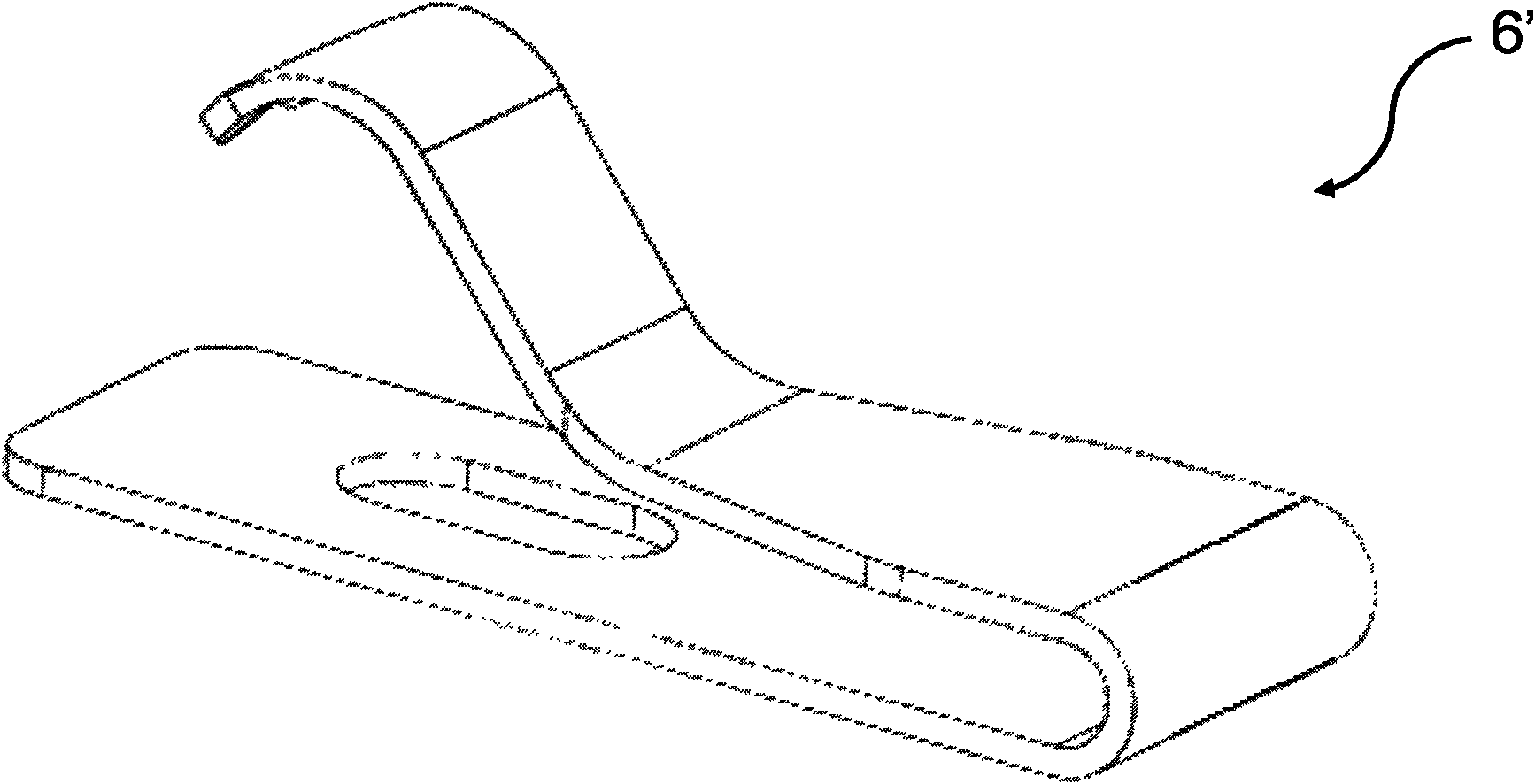

[0034] Please refer to image 3 , 4 The shrapnel 2 shown is made by bending a copper sheet, and is soldered to the substrate 1 by the surface adhesion method, and the conductive material of the shrapnel 2 itself is used for electrical connection; it includes a section of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com