Probe base

A technology of probes and ribs, which is applied in the field of probe bases, can solve the problems of high stability, inapplicability to the installation of probe bases, and the inability to give components, etc., to achieve high stability, simple manufacturing, and reduce stress formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

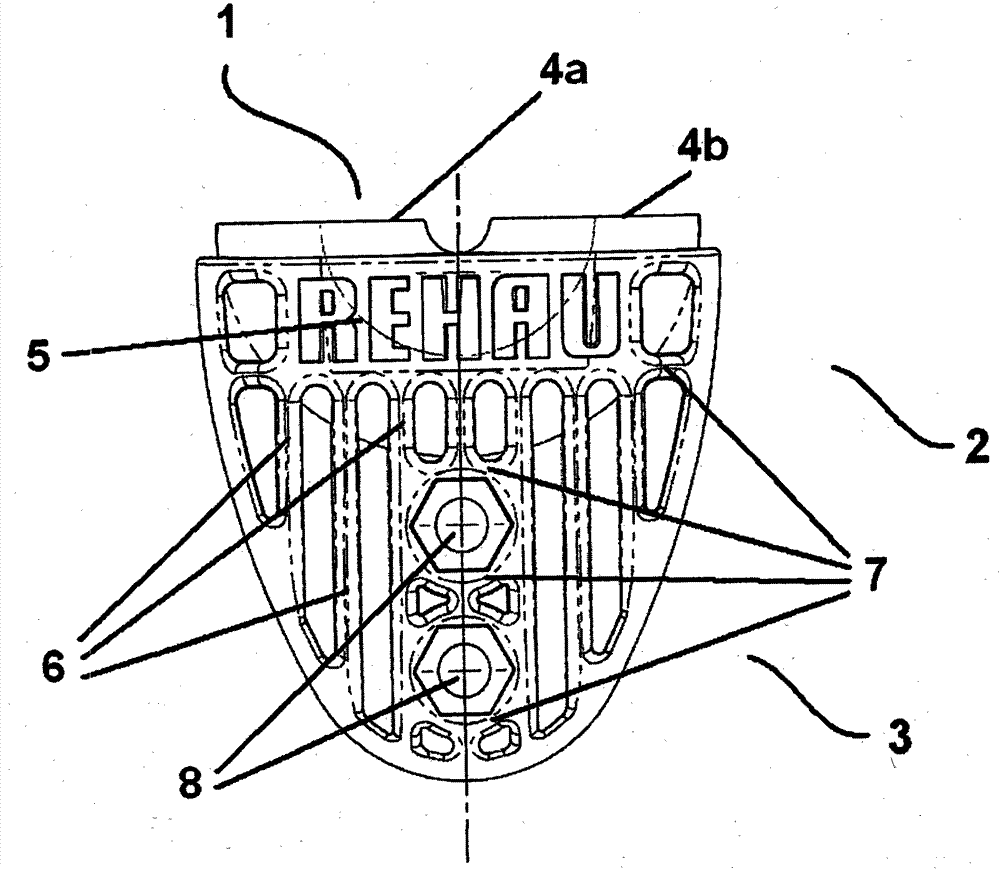

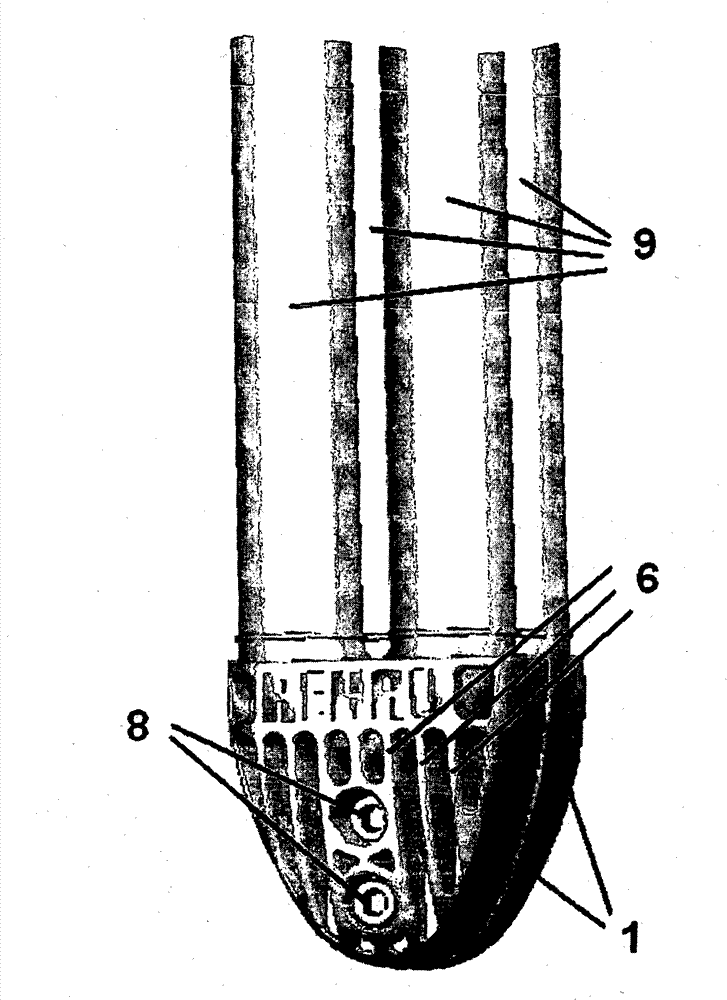

[0035] exist figure 1 A plan view of a probe base 1 according to the invention is shown in . The probe base 1 has a fluid guiding part 2 and a base part 3 . Tube elbow ends 4 a , 4 b are formed on the fluid guide part 2 for connecting the probe base 1 to a tube, not shown here.

[0036] exist figure 1 The pipe bend 5 shown in is an integral part of the fluid guide part 2 . The rib 6 is arranged on the probe base 1 such that the rib extends substantially between the fluid guiding part 2 and the base part 3 in the direction of the axis of the tube, not shown here.

[0037] Furthermore, connecting ribs 7 are arranged between the ribs 6 and extend substantially perpendicular to the ribs 6 . Two such probe bases 1 can be connected in pairs by means of connecting elements through through holes 8 . Mechanisms for force transmission can also be mounted on the through-opening 8 .

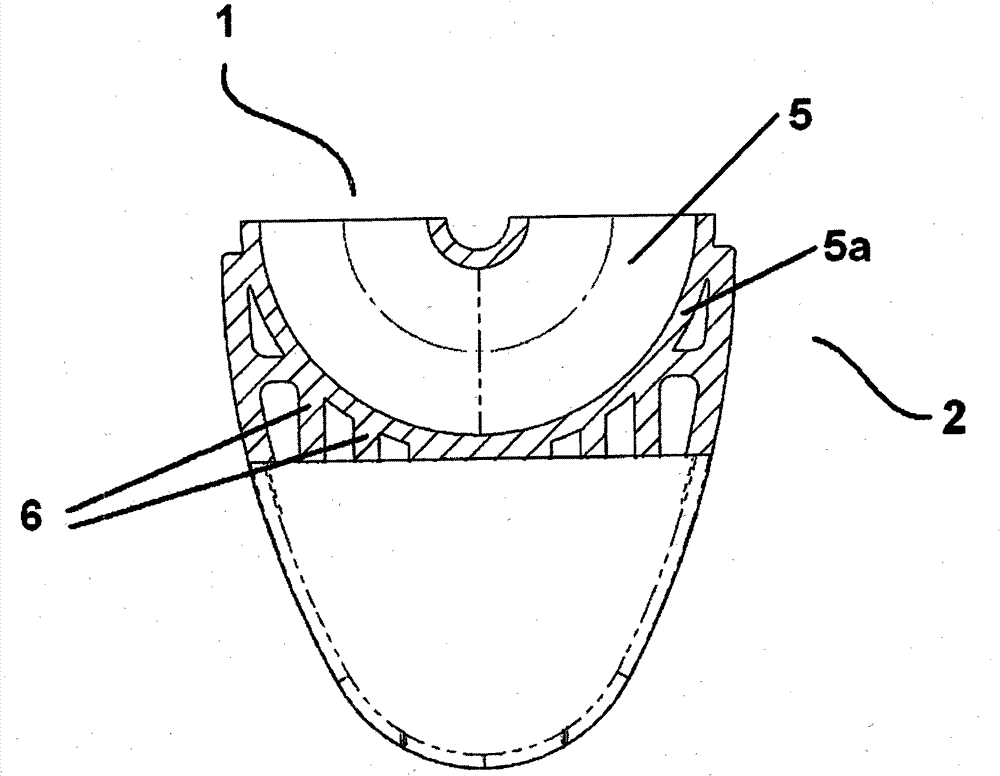

[0038] according to figure 2 , shown in a cross-sectional view, a pipe bend 5 is formed in the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com