Drive means and chain drive

A driving device and chain transmission technology, which is applied in the direction of transmission devices, belts/chains/gears, escalators, etc., can solve problems such as interference, damage to the stability of the conveyor belt/escalator, and bearing wear, so as to achieve durable costs, avoid wear and tear. Possibly with the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

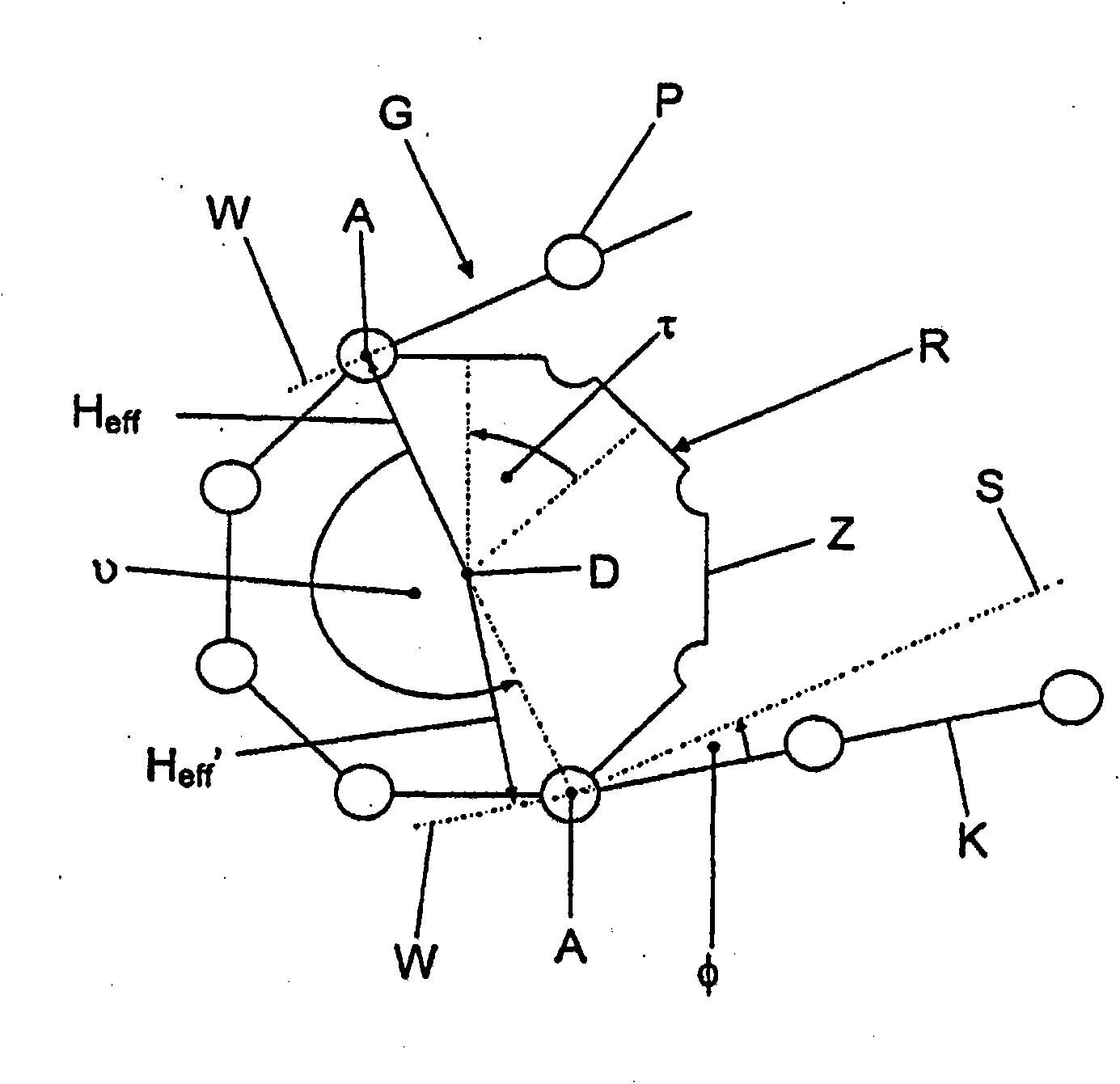

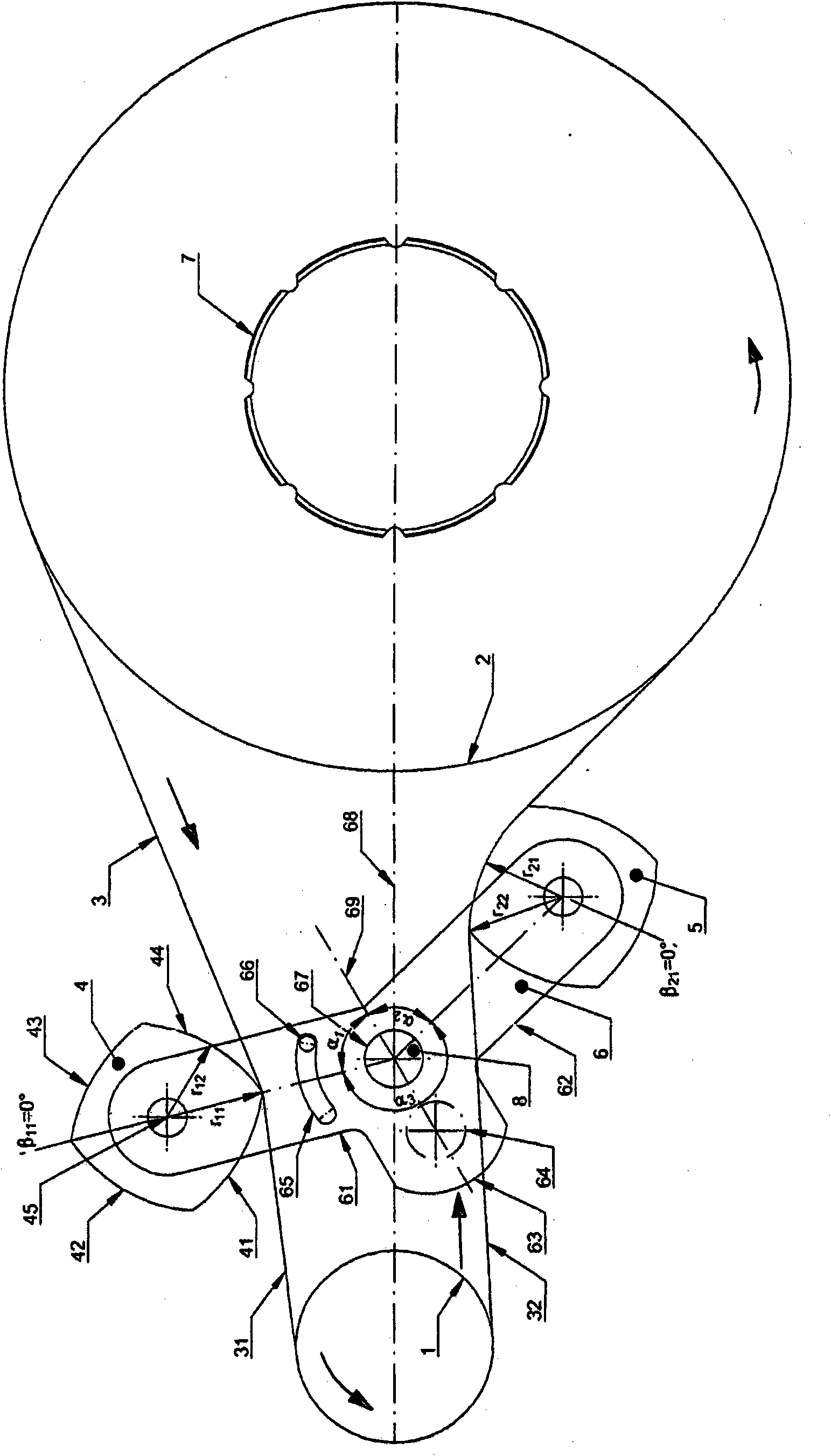

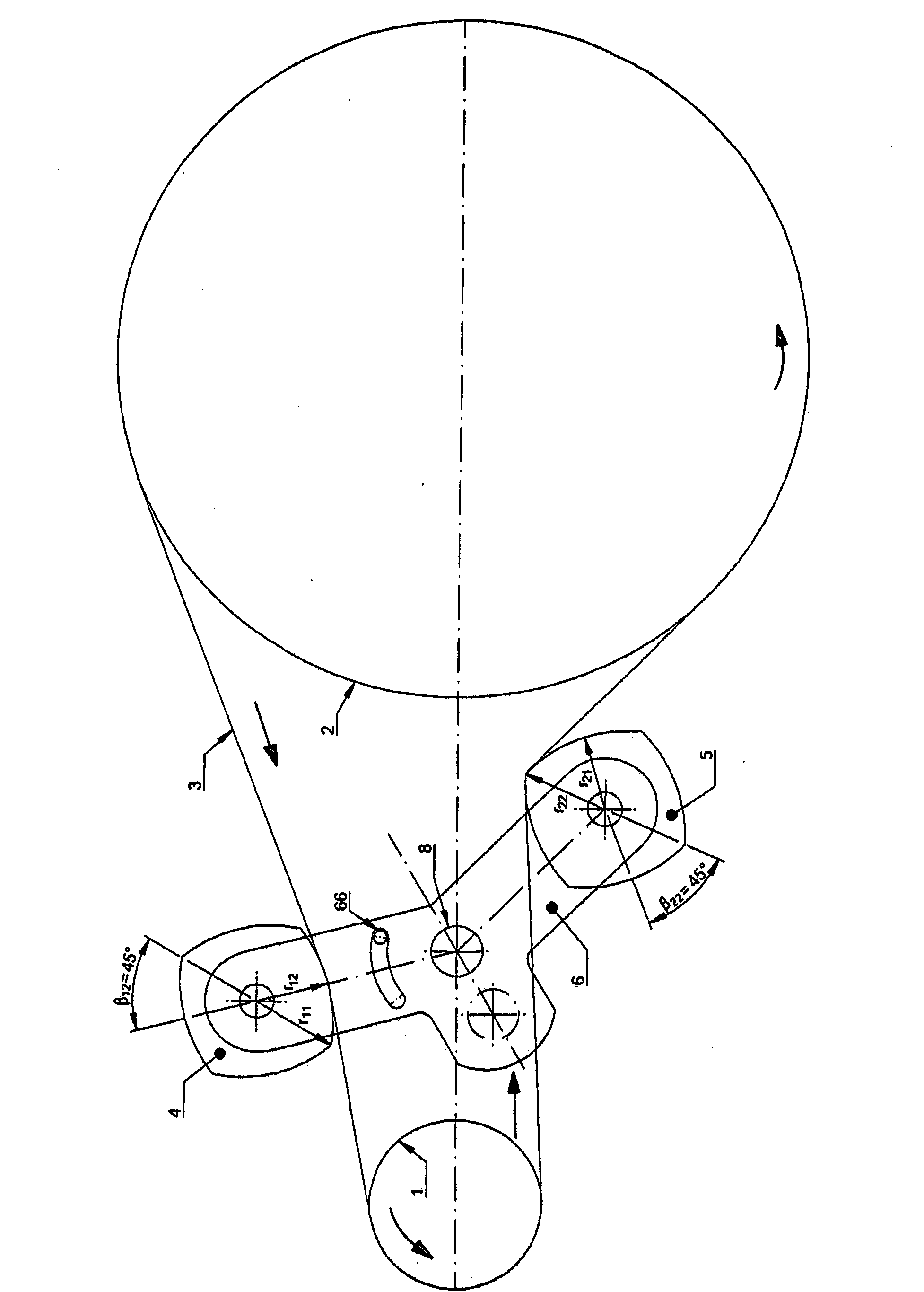

[0084] The drive according to the invention basically comprises a first traction device wheel 1 , a second traction device wheel 2 , a traction device 3 , a first equalizing wheel 4 , a second equalizing wheel 5 and a rocker 6 .

[0085] The chain drive according to the invention comprises at least one drive according to the invention and at least one sprocket 7 which is driven by the drive. In particular, the chain drive according to the invention comprises a conveyor chain, preferably a stair chain or a tread chain, on which a plurality of escalator steps or treads are mounted, and the chain drive according to the invention also comprises another ( not shown) sprockets, where the conveyor chain runs on sprocket 7 and another sprocket.

[0086] The traction device 3 is, for example, a chain, preferably a roller chain, arranged around the first traction device wheel 1 and the second traction device wheel 2 in the form of an endless chain. This forms a first part of the tracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com