Diffraction optical element and method for manufacturing same

A technology of diffractive optical elements and diffraction gratings, applied in optical elements, diffraction gratings, optics, etc., can solve the problems of MTF characteristic dispersion and inability to mass-produce white diffractive optical elements, so as to ensure low cost and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of a diffractive optical element employing the present invention will be described with reference to the drawings.

[0031] (First Embodiment) First, an embodiment using a diffractive optical element of the present invention will be described.

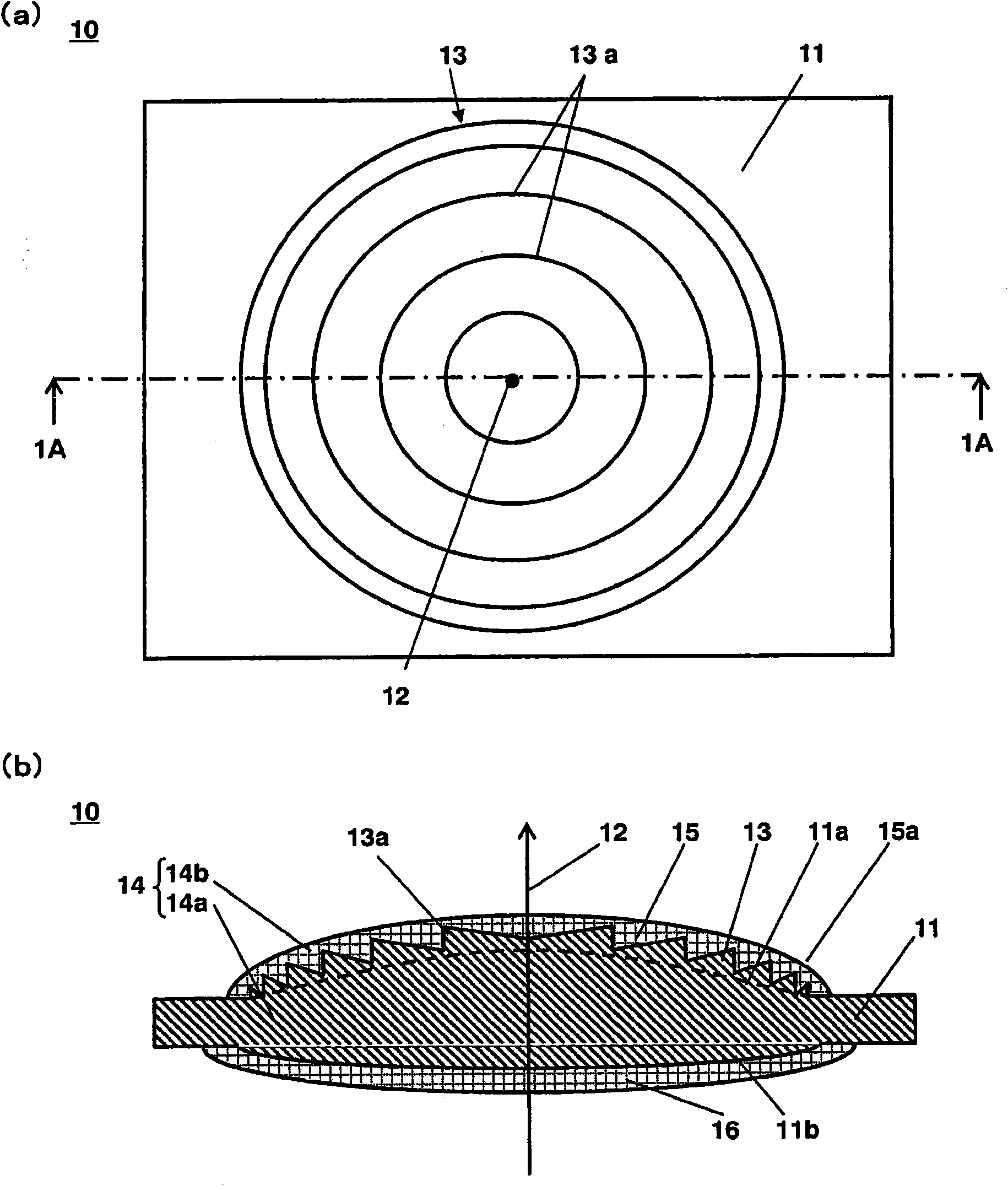

[0032] refer to figure 1 . figure 1 (a) is a plan view of the diffractive optical element 10 in this embodiment, figure 1 (b) is figure 1 1A-1A line sectional view in (a).

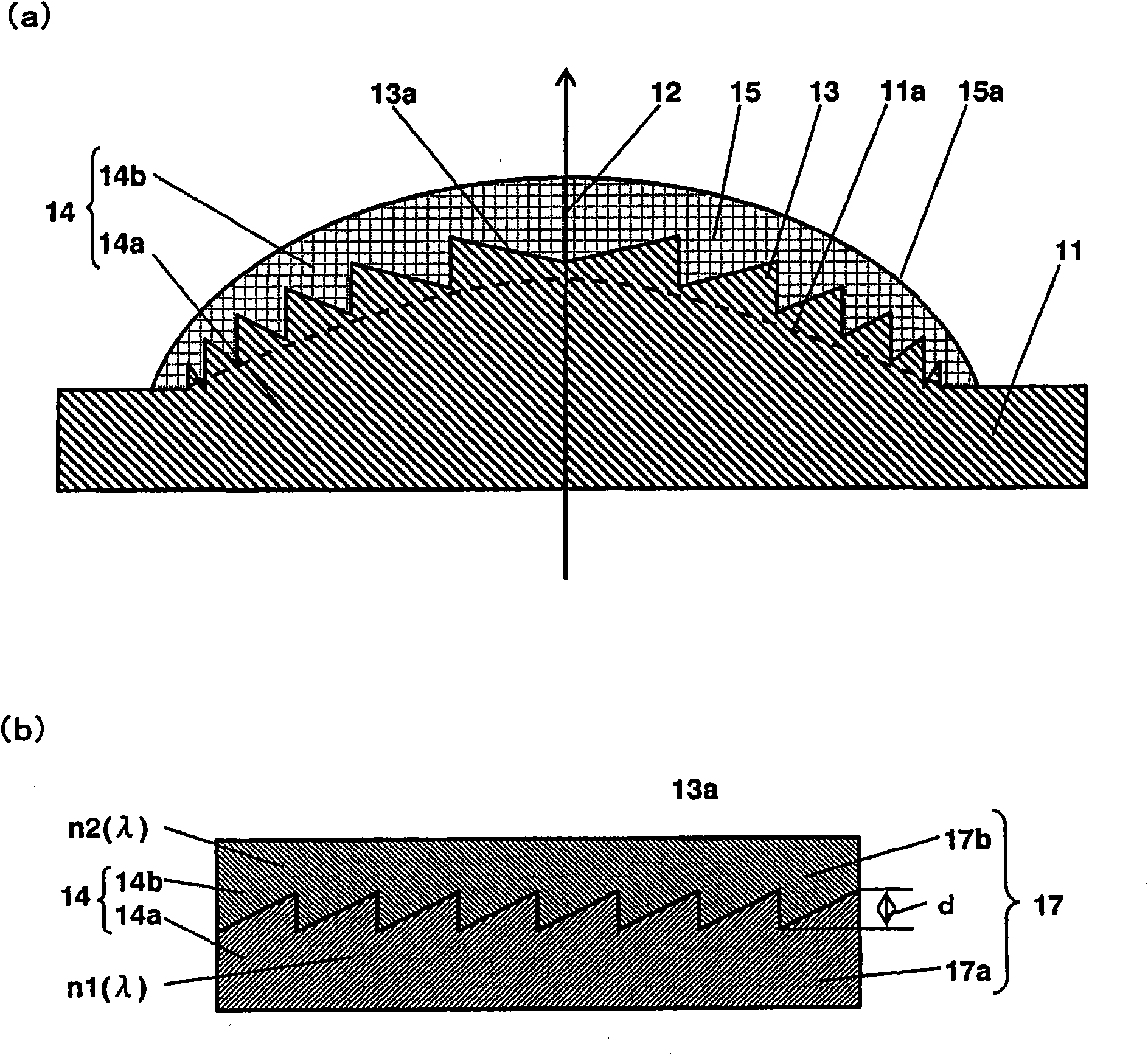

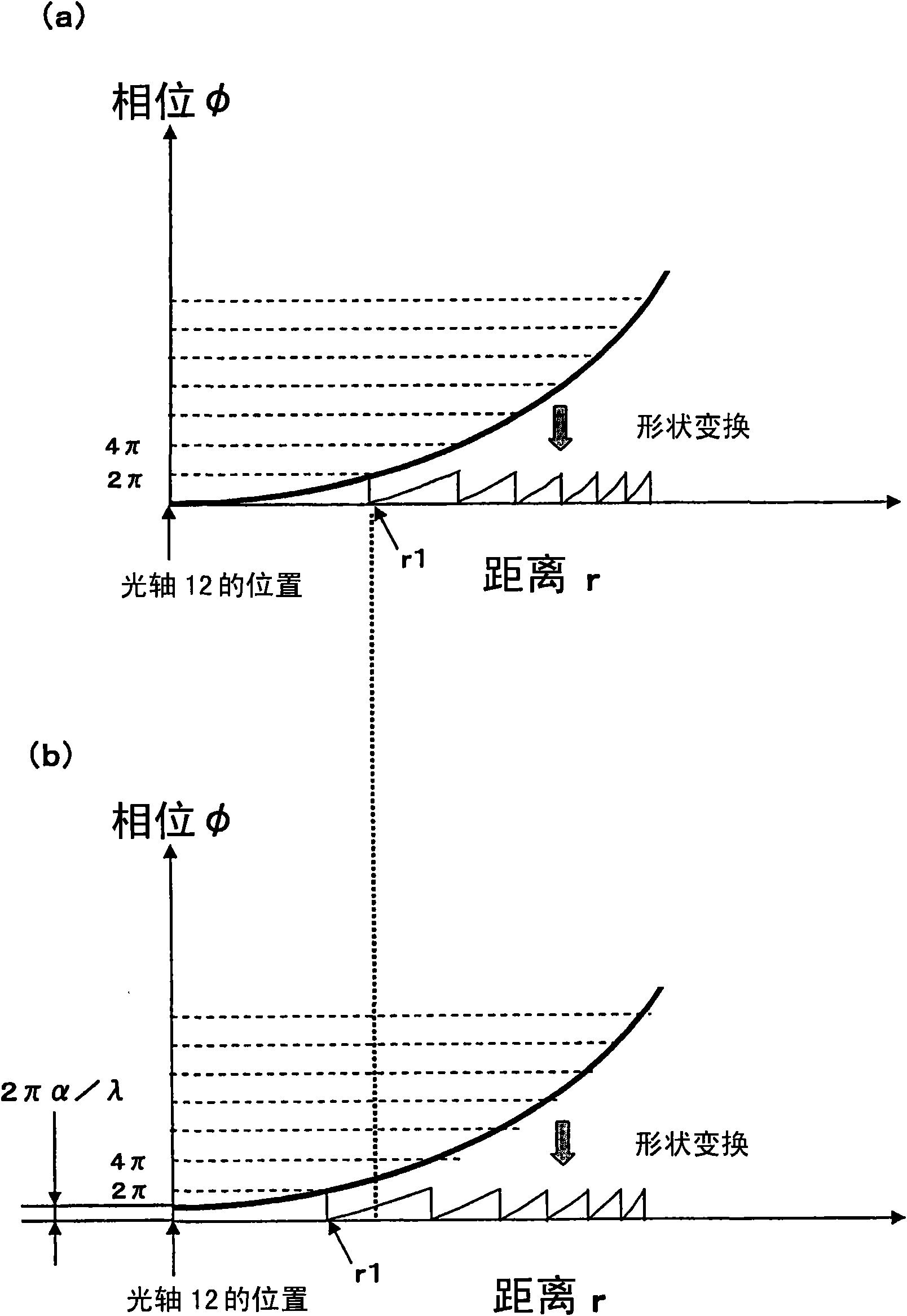

[0033] The diffractive optical element 10 in this embodiment, such as figure 1 As shown in (a) and (b), a lens base 11 (the lens base 11 is provided with a blazed diffraction grating 13 on the aspherical surface (first surface 11a)) and an optical adjustment layer 15 (the optical adjustment layer 15 covers the diffraction grating 13. The lens substrate 11 is formed by the first material 14a; the optical adjustment layer 15 is formed by the second material 14b whose refractive index is greater than the first material 14a.As a who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com