Blowing additive metering system

A metering system and admixture technology, which is applied in the field of metering systems, can solve problems such as difficulty in ensuring the metering accuracy of admixtures, constraints on the stability of metering accuracy, and prolonging the stirring time, so as to shorten the stirring time, reduce the use cost and electricity cost , Improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

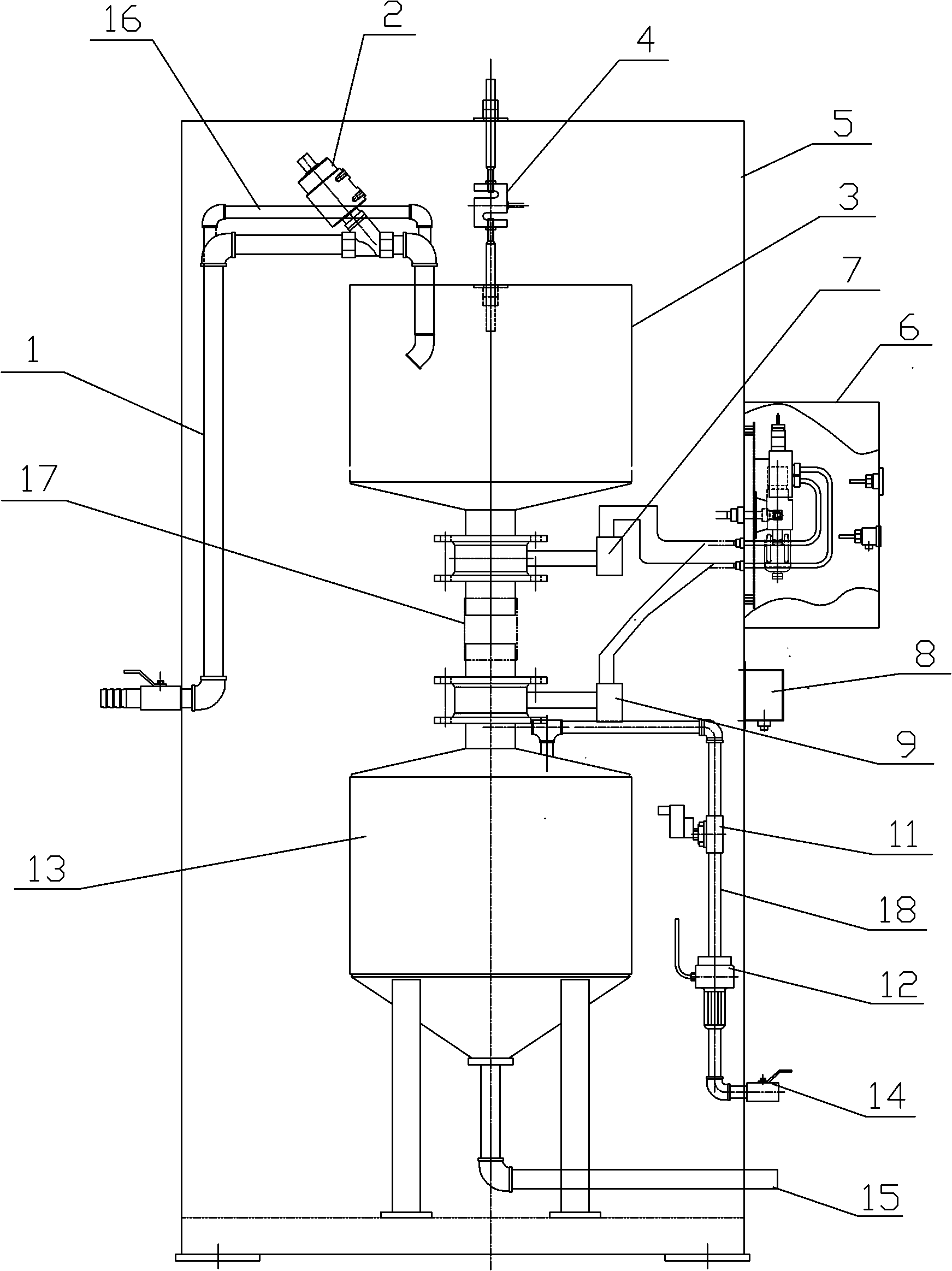

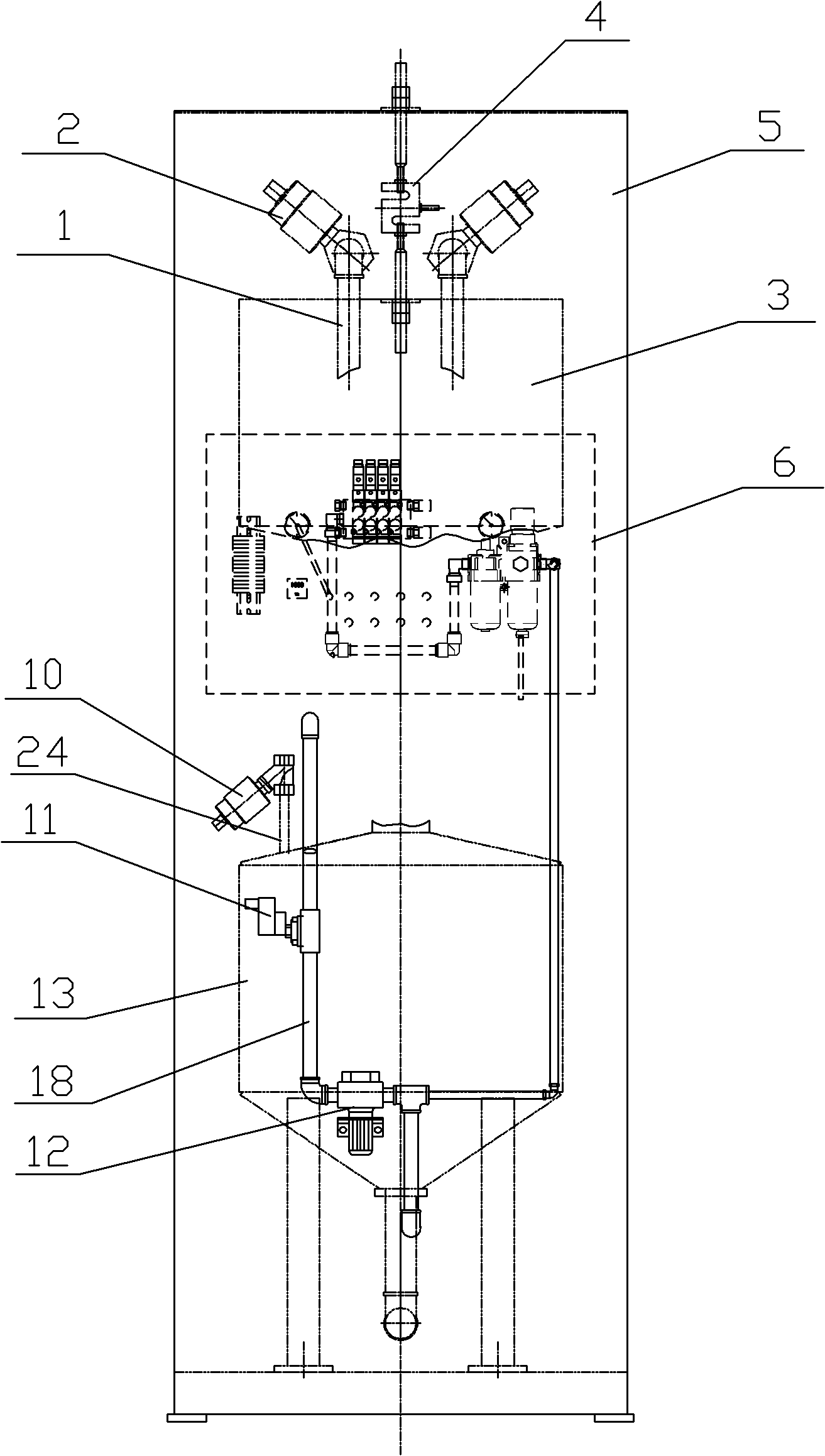

[0014] Refer to the attached figure 1 To attach Figure 4 The air blowing admixture metering system of the present invention will be described in detail below.

[0015] The air blowing admixture metering system of the present invention comprises an admixture scale, the admixture scale includes a scale body 3, a scale body unloading butterfly valve 7 and a sensor assembly, and the sensor assembly includes a sensor 4 and a sensor assembly Junction box 8, the sensor 4 is connected to the sensor junction box 8, the sensor 4 is arranged on the top of the scale body 3, the discharge butterfly valve 7 of the scale body is arranged at the bottom of the scale body 3, and the top of the scale body 3 A cleaning pipeline 16 and an upper admixture pipeline 1 are provided. The upper admixture pipeline 1 is provided with an upper admixture valve 2. The upper admixture pipeline 1 is two-way, and the admixture The scale is connected with the air blowing admixture device.

[0016] The air-bl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap