Shearing type elastic sleeper compound shock absorber

A shock absorber and shear type technology, applied in the field of sleeper shock absorbers, can solve the problems of inability to effectively absorb high-frequency vibration energy of rails, poor vibration and noise reduction, poor assembly accuracy, etc., to avoid abnormal wave-shaped wear, The effect of good vibration and noise reduction and reduced installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

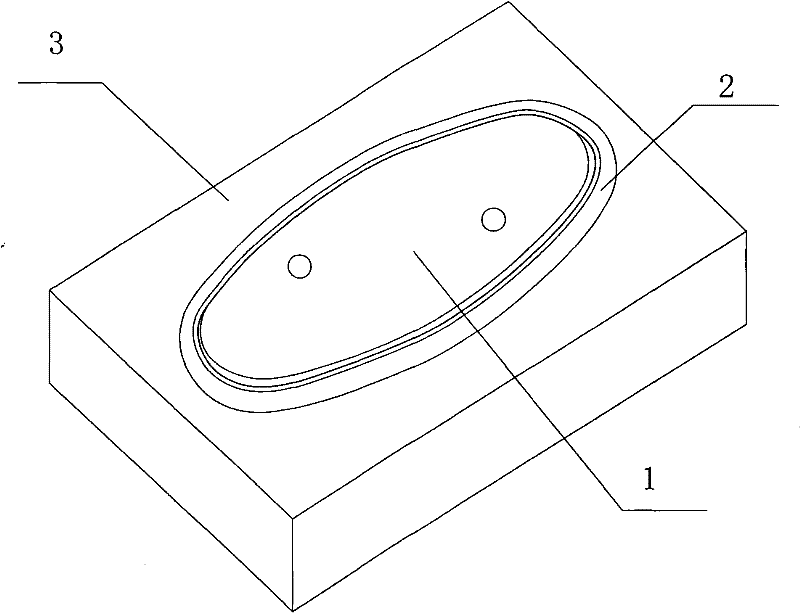

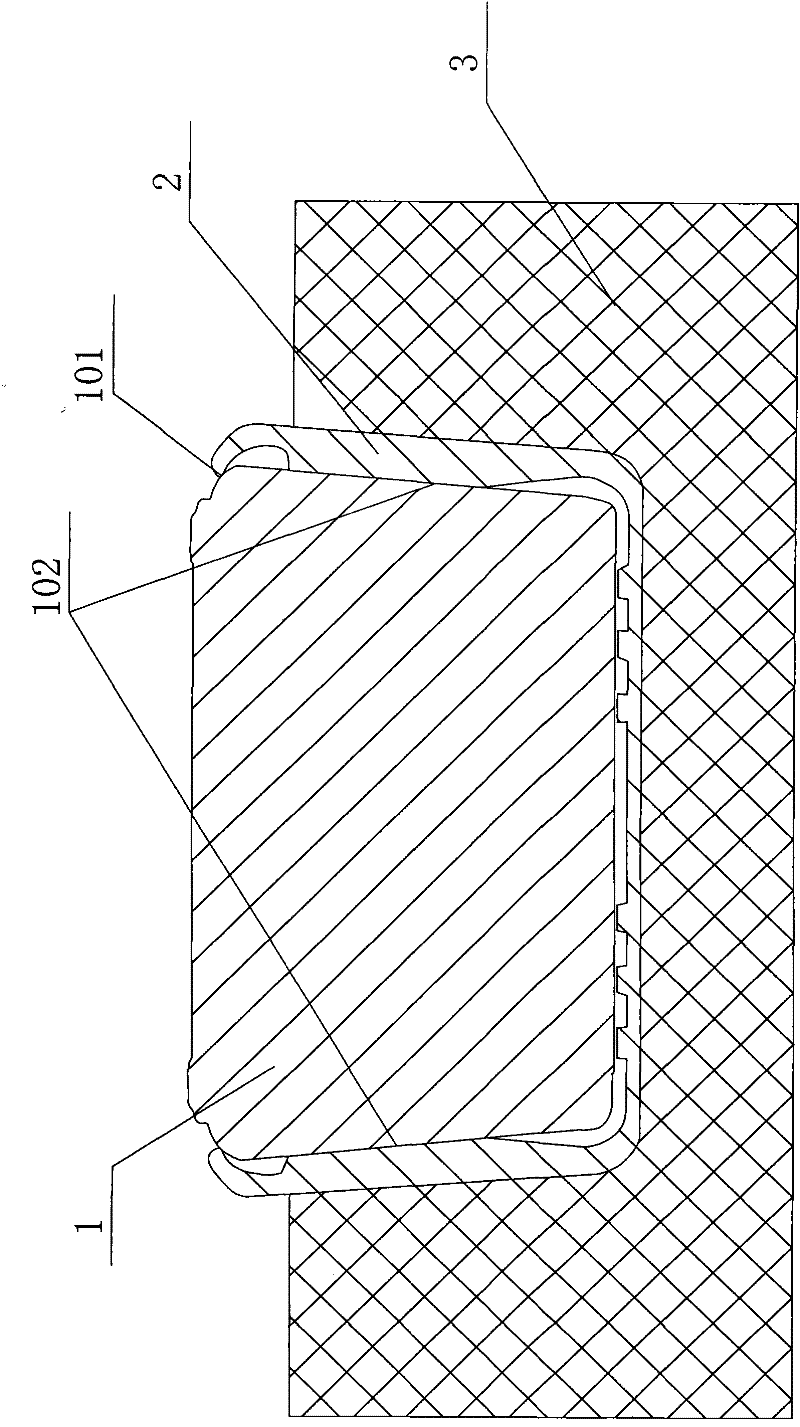

[0021] see Figure 1~2 , figure 1 It is a schematic diagram of the three-dimensional structure of the shear type elastic sleeper composite shock absorber of the present invention. figure 2 for figure 1 elevation view. Depend on figure 1 and figure 2 It can be seen that the shear type elastic sleeper composite shock absorber of the present invention comprises a concrete sleeper 1, a rubber shock absorber 2 and an integral track bed 3 of cast-in-place concrete. The concrete sleeper 1 is in the shape of an ellipse table, and the top end surface The end surface of the big bottom is small, and the outer edge of the top surface of the concrete sleeper 1 is provided with a circle of grooves 101 , and the middle section of the concrete sleeper 1 is sunken inward, forming a circle of sunken areas 102 .

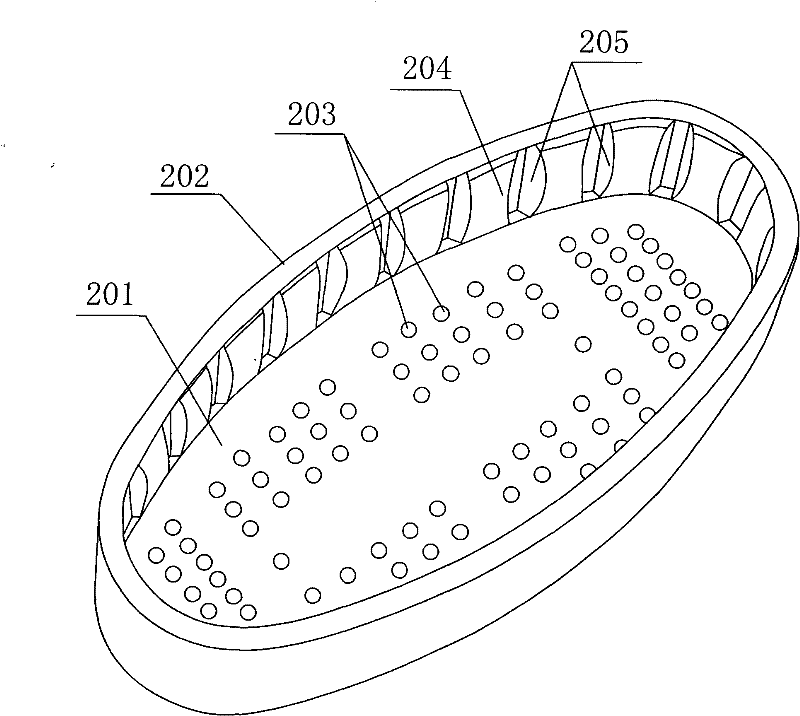

[0022] see Figure 3-4 , image 3 It is a schematic diagram of the three-dimensional structure of the rubber shock absorber of the present invention. Figure 4 for image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com