Liquid conveying and heating pipe

A technology for heating pipes and conveying pipes, which is applied in the direction of heating/cooling of pipes, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of uneven heating of heating belts, slow heating, and difficult to control the temperature of heating liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

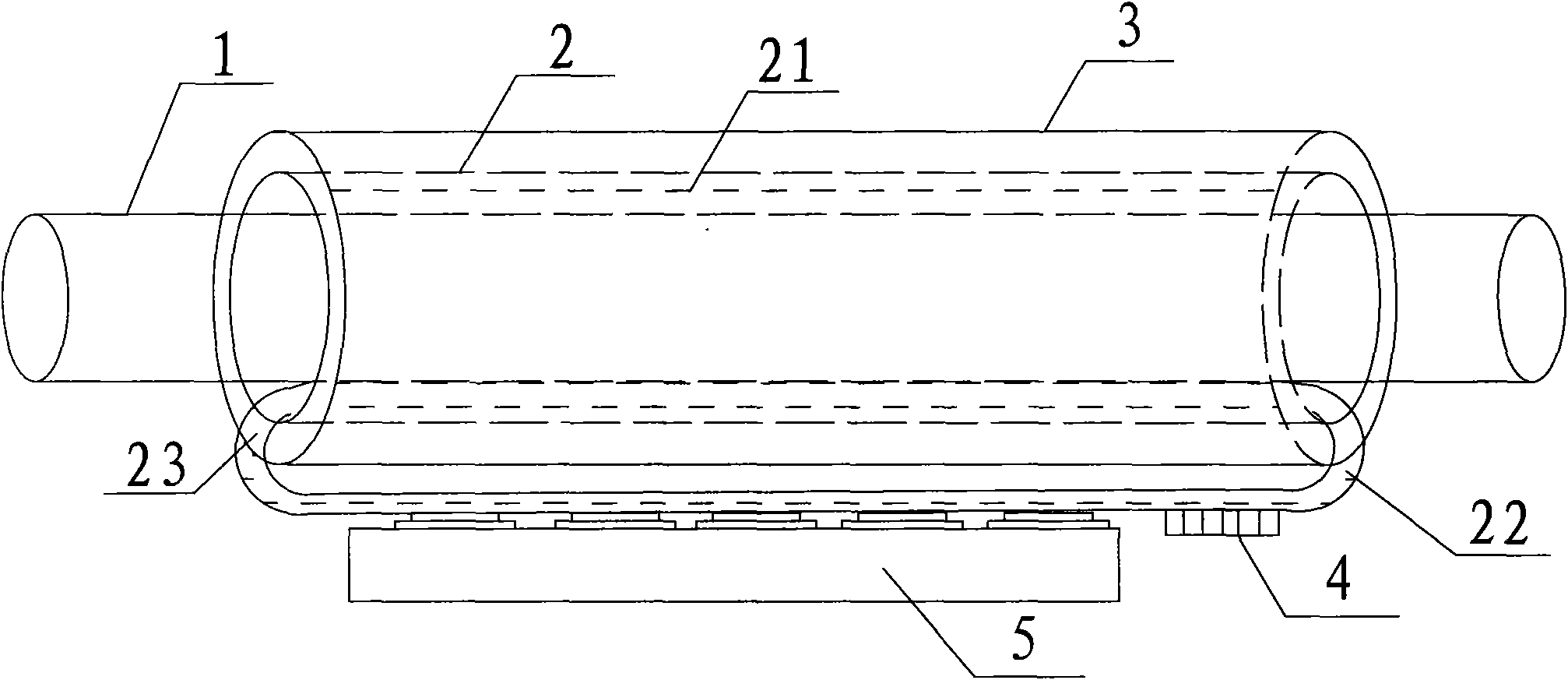

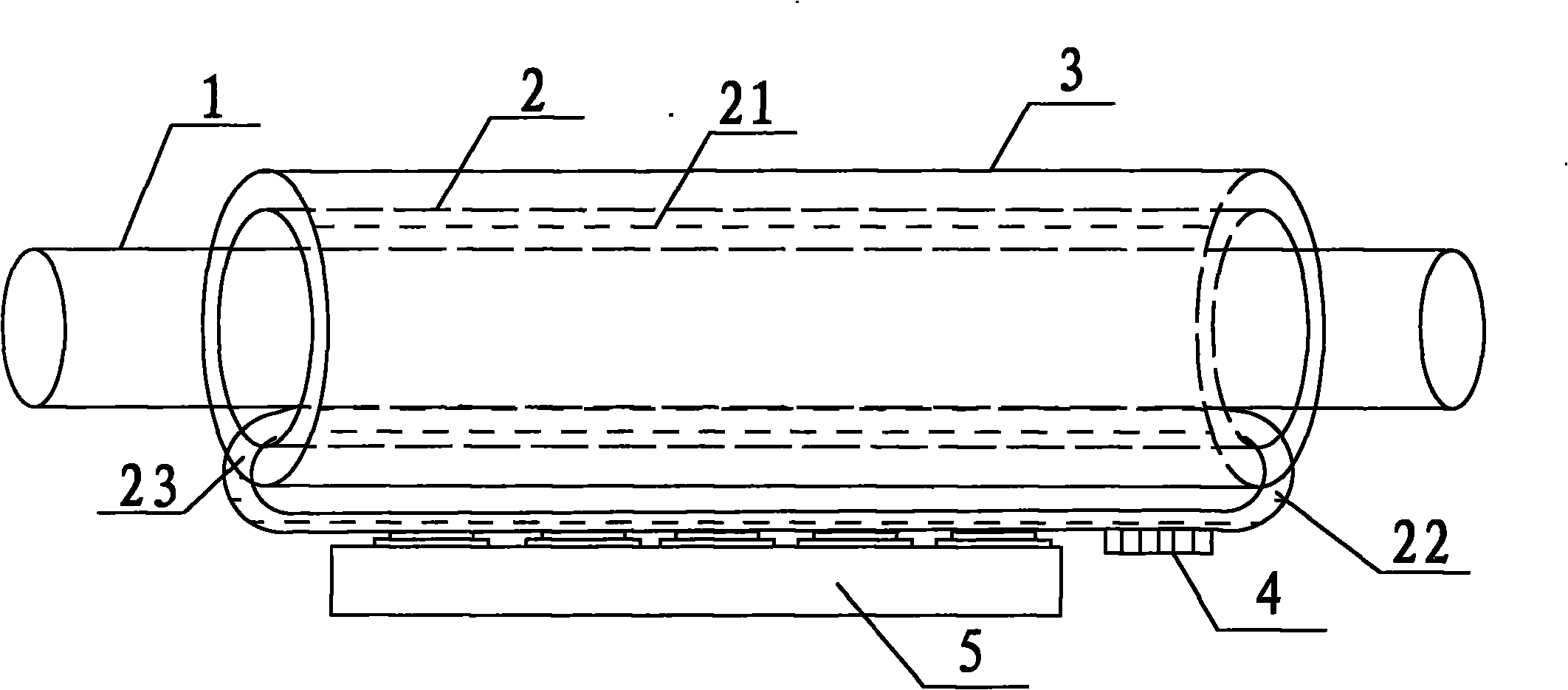

[0010] figure 1 A liquid conveying heating pipe is shown. A closed hot water pipe 2 is put on the outside of the conveying pipe 1. The inside of the hot water pipe 2 is equipped with a heat-conducting liquid 21. A heater is connected outside the hot water pipe 2. 5. A thermostat 4 is installed on one side of the heater 5, and a water inlet 22 and an outlet 23 are provided on both sides of the hot water pipe 2, which function to form a circulating liquid flow circuit with the heater 5 to maintain The temperature of the liquid 21 is constant in the closed hot water pipe 2, and the heating temperature can be controlled as required by the display of the external temperature controller 4.

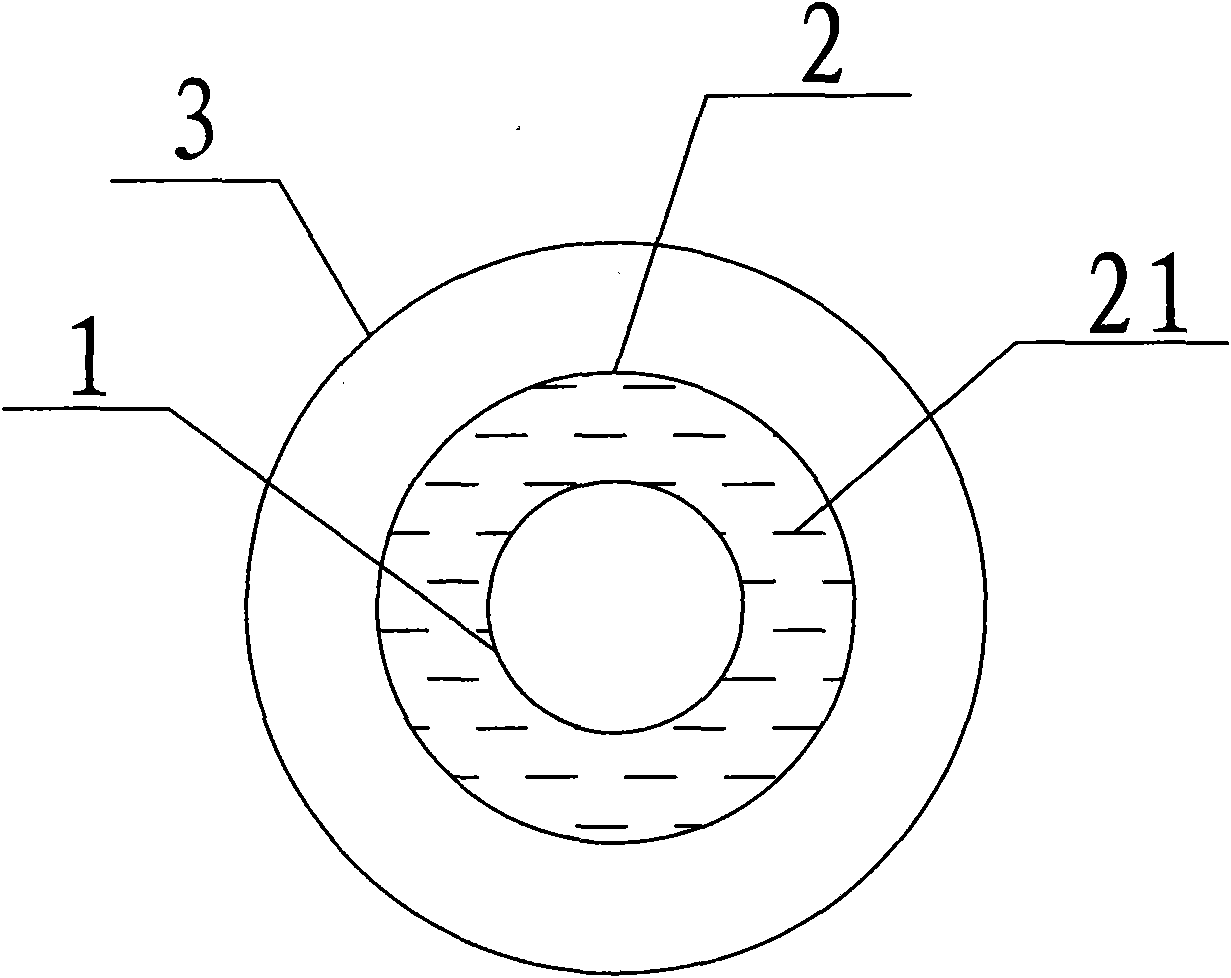

[0011] figure 2 The schematic diagram of the outer casing of the delivery pipe 1 is shown. A fixed pipe 3 is sheathed outside the hot water pipe 2 to fix the hot water official channel on the outside of the delivery pipe 1 .

[0012] Embed the delivery pipe 1 into the closed hot water pipe 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com