Integrated two-layer reverse energy-saving tunnel kiln

A tunnel kiln, double-layer technology, applied in the field of kilns, can solve the problems of high energy consumption, slow heat dissipation in the annealing section, and many people, and achieve the effect of improving the transmission speed and saving the cost of building a kiln.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

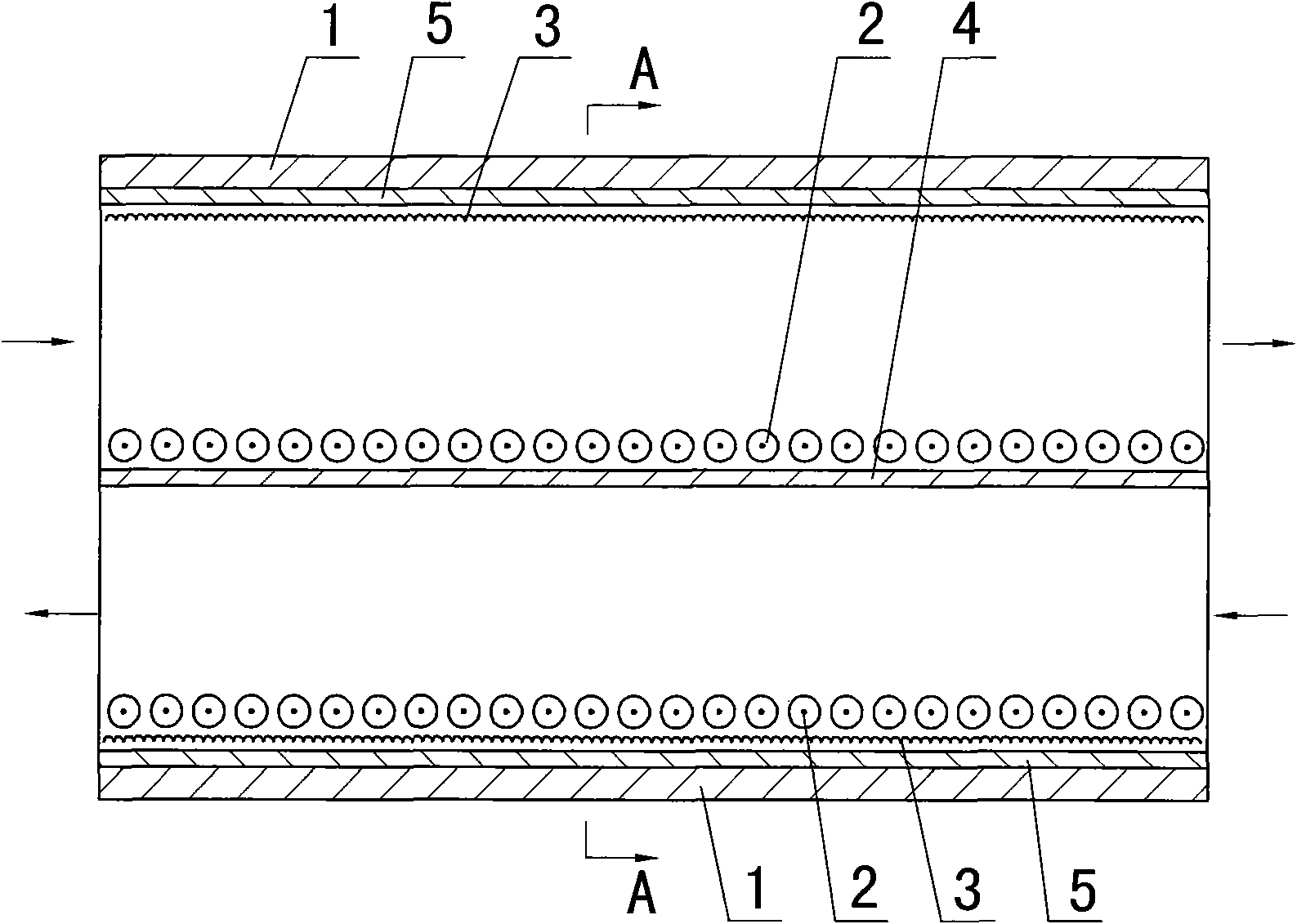

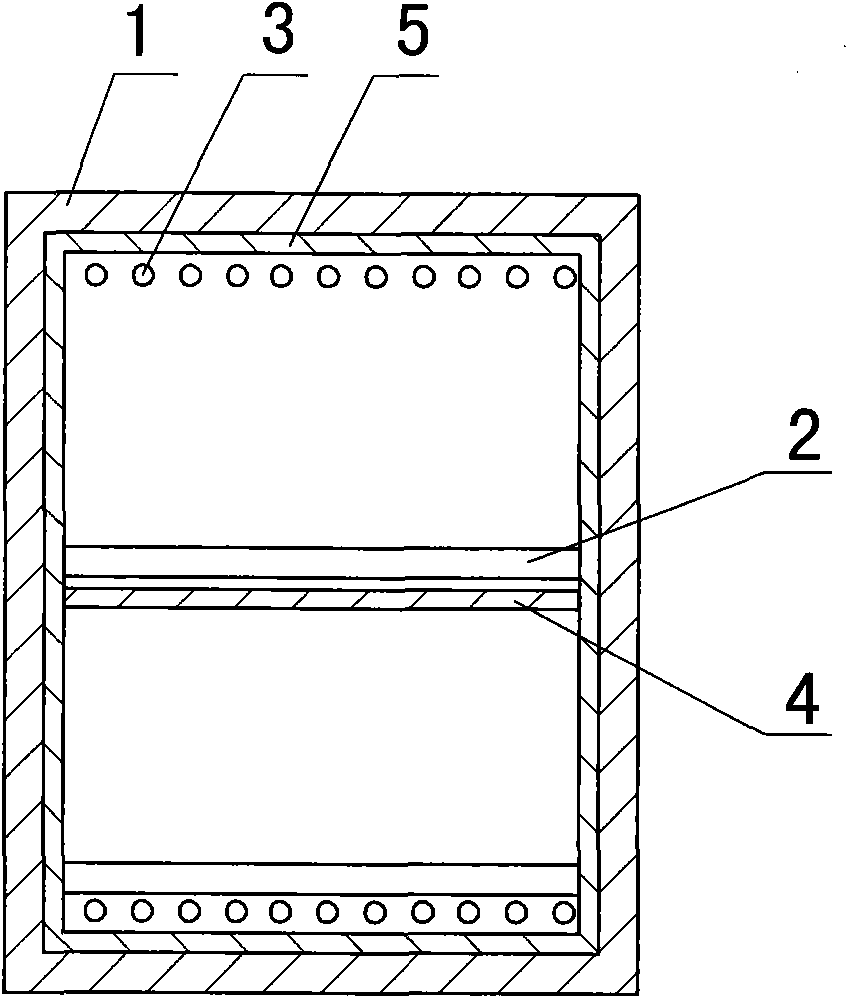

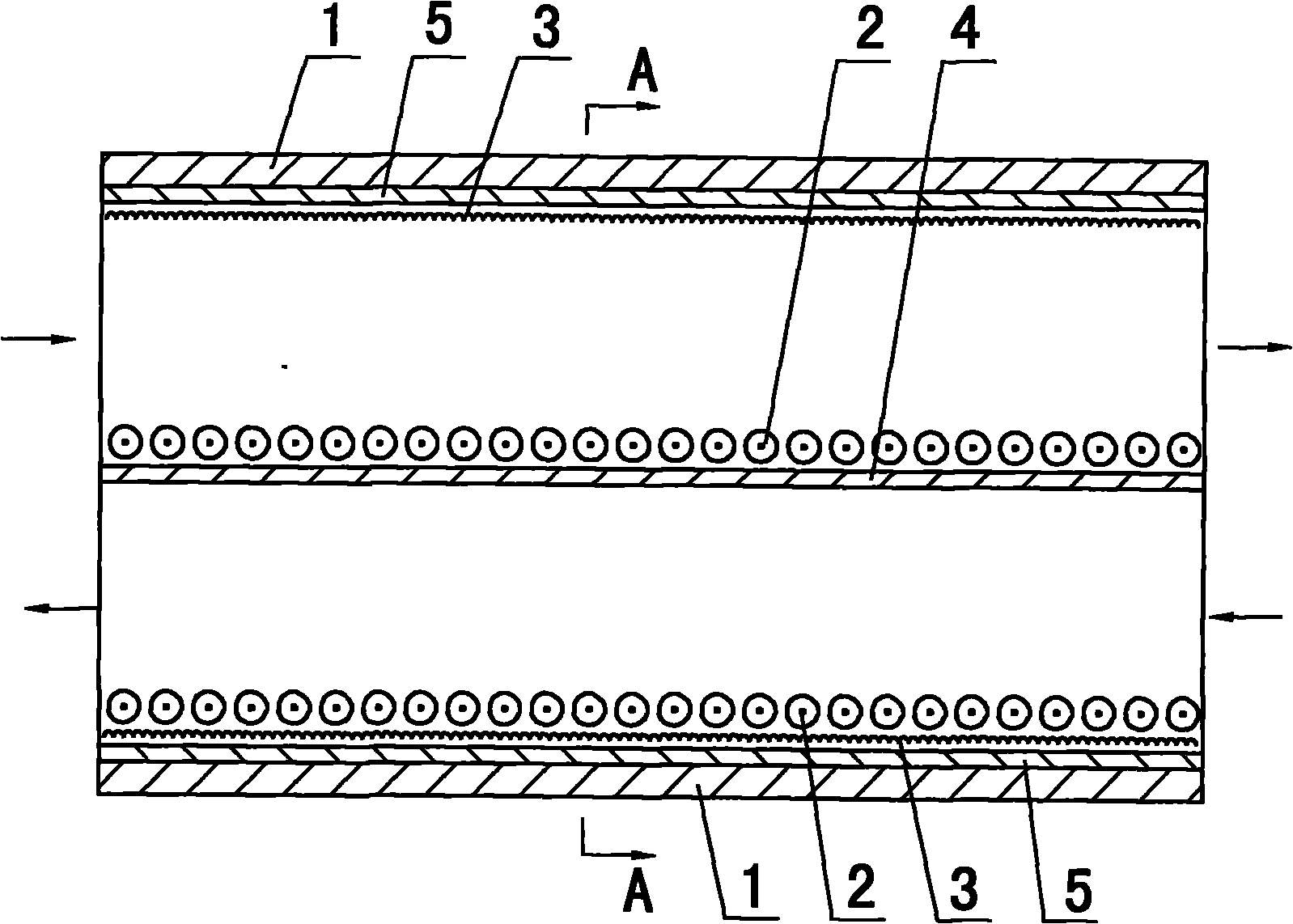

[0016] exist Figure 1-2 In the shown embodiment: the inner wall of the kiln body 1 is provided with an insulating layer 5, the electric furnace wire 3 is evenly installed close to the top surface and the bottom surface of the kiln body 1, and a horizontal partition 4 is added to horizontally divide the space in the kiln body 1 into upper, lower, and upper sides. The lower two layers, close to the bottom of each layer, are provided with drive rollers 2 along the direction of travel, and the rotation directions of the two layers of drive rollers 2 are opposite, thereby ensuring that the materials in the upper and lower layers enter and exit in opposite directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com