Dual force ram drive for a screw press

A driving device and screw-driven technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of high cost, large physical size, and high power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

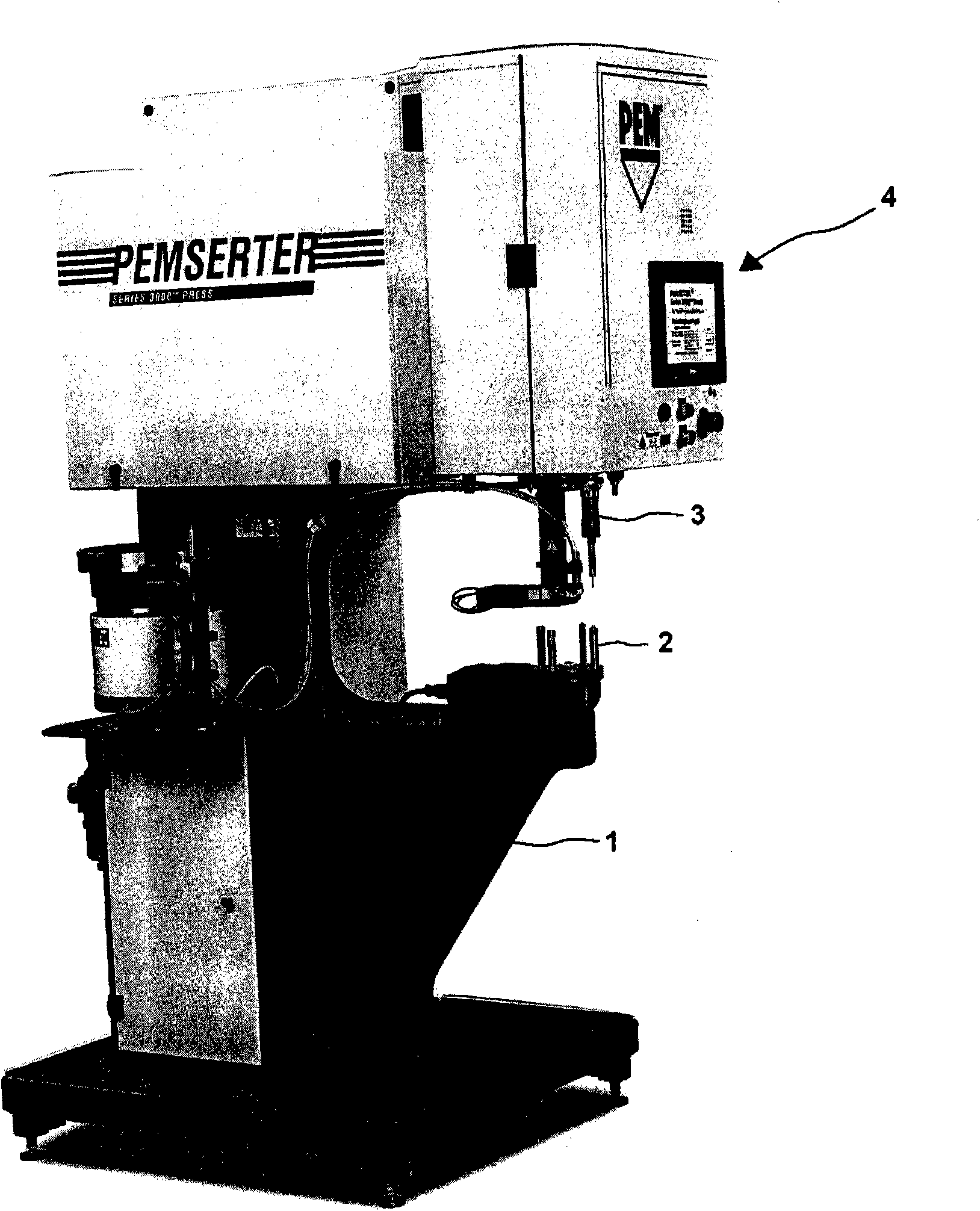

[0015] now refer to figure 1 , shows a punching machine 4 embodying the invention comprising a C-shaped frame 1 supporting an anvil 2 reciprocally impacted by a ram 3 .

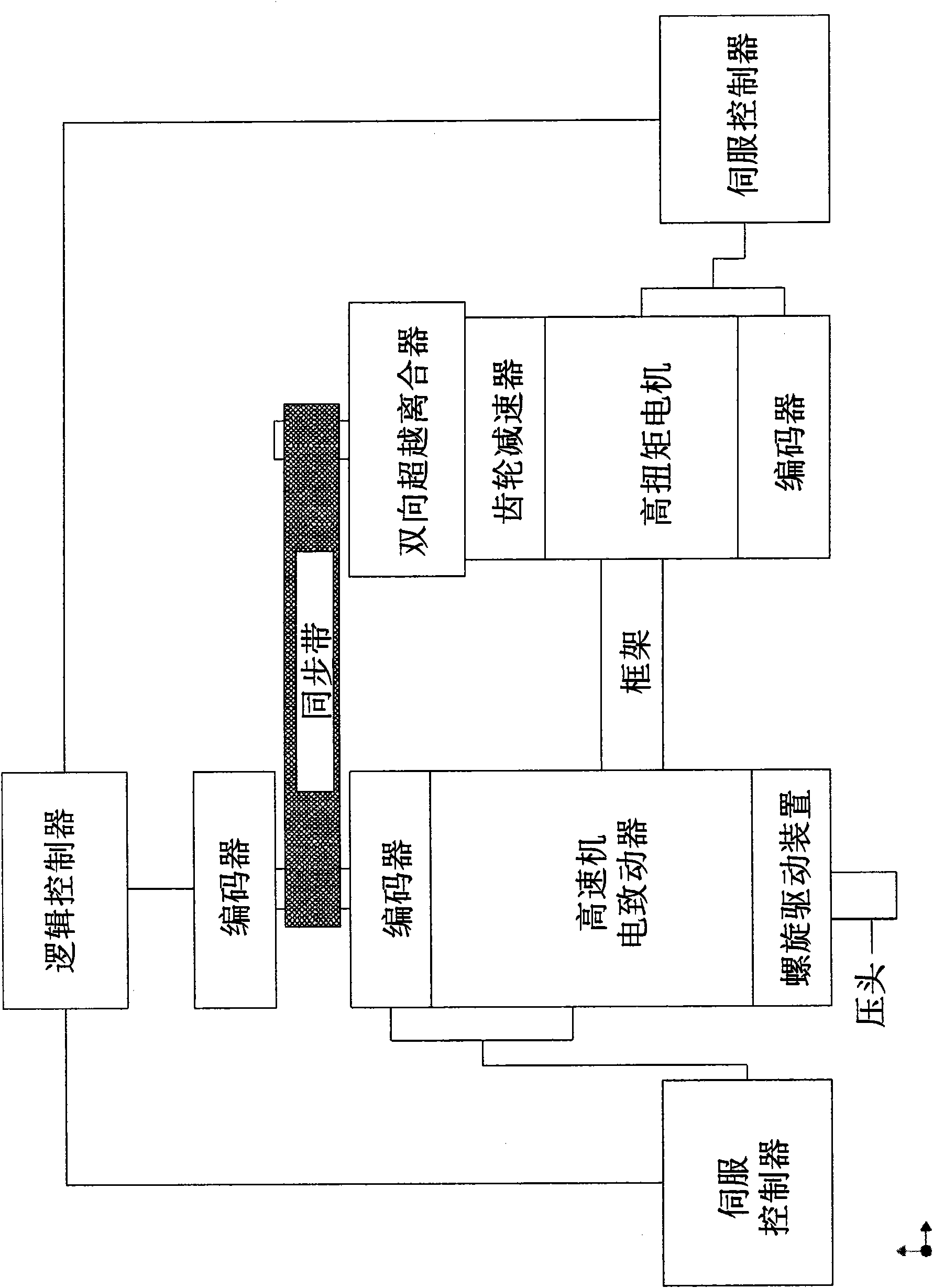

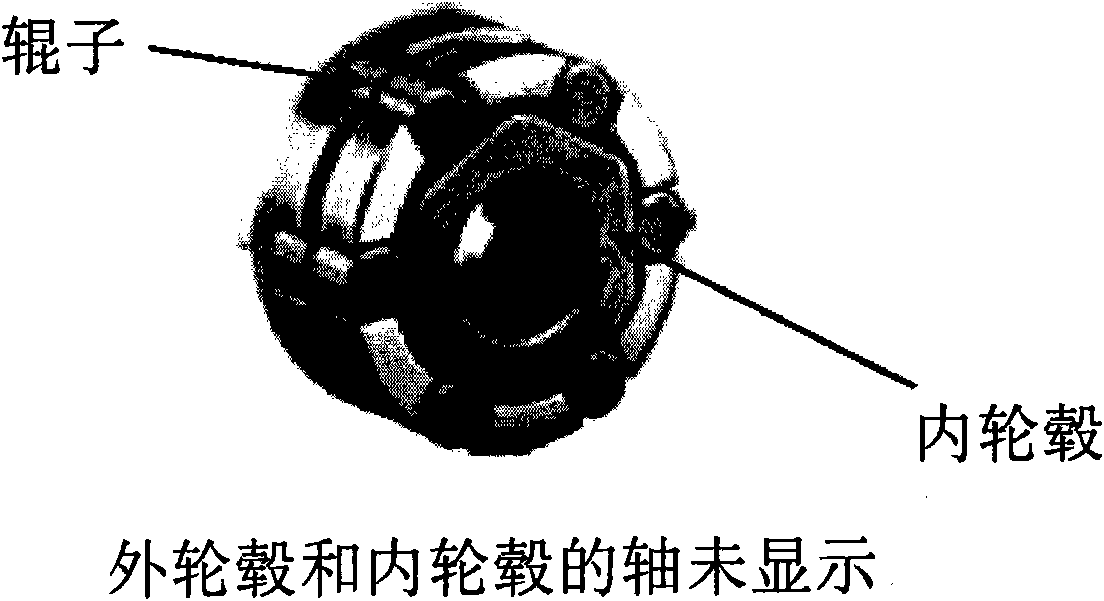

[0016] now refer to figure 2 , which discloses the main components of the invention, including a frame for supporting the basic mechanical components of the invention, including high-speed mechanical drives and high-torque motors. The frame also supports a screw drive which can be operated in both directions by high speed or low speed motor means. A bi-directional self-disengaging clutch is connected to a high torque motor unit which includes a motor / gear reducer combination. The programmable logic controller regulates the operation of the two motors through the screw drive device, thereby regulating the movement of the ram. The two-way clutch is connected to the main shaft of the screw drive via a timing belt. The logic controller regulates the movement of the ram according to a stamping profile, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com