Thermal treatment vacuum furnace material transferring device

A technology of transfer device and vacuum furnace, applied in heat treatment equipment, quenching device, furnace, etc., can solve the problems that materials can not withstand friction on it, movement speed limitation, poor adaptability to heavy loads, etc., to achieve reliable work and avoid material friction , the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

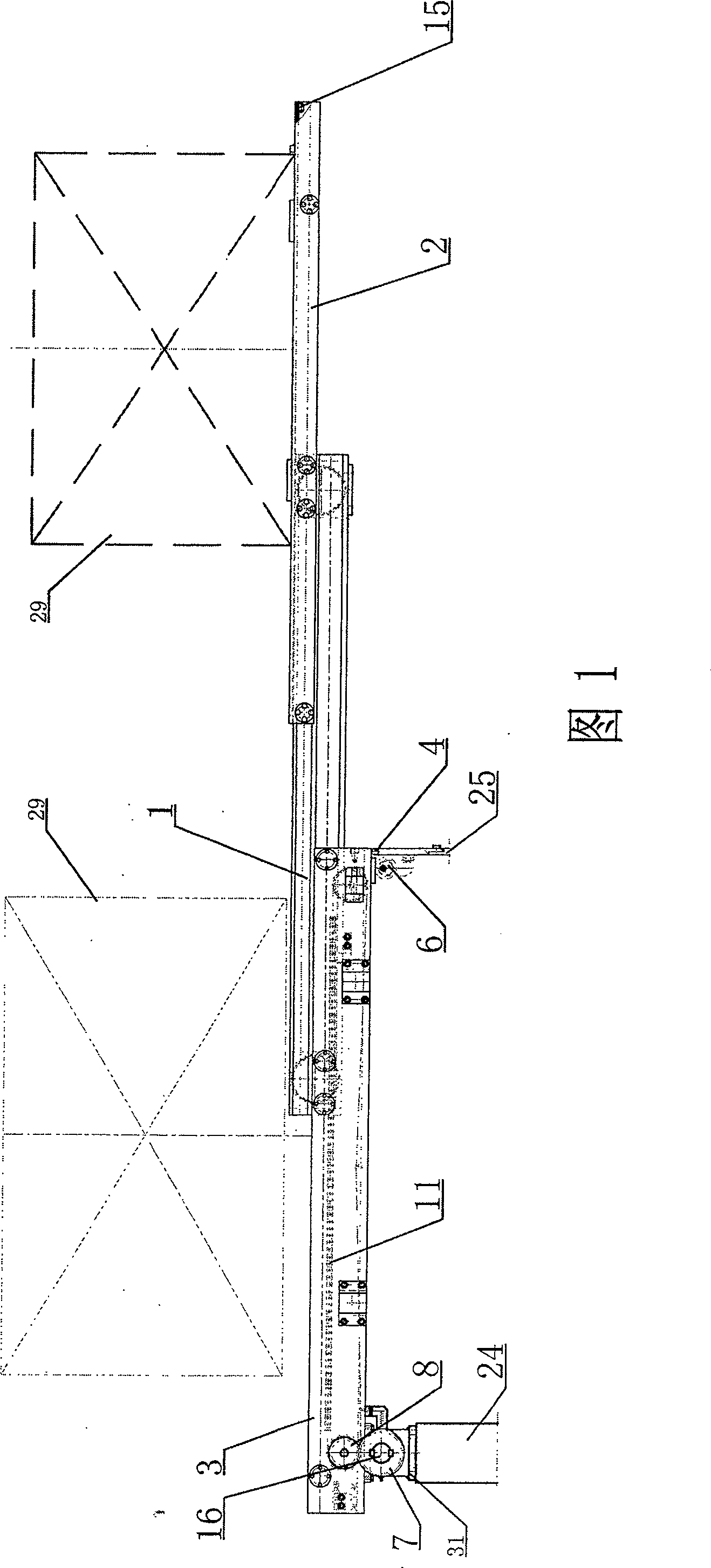

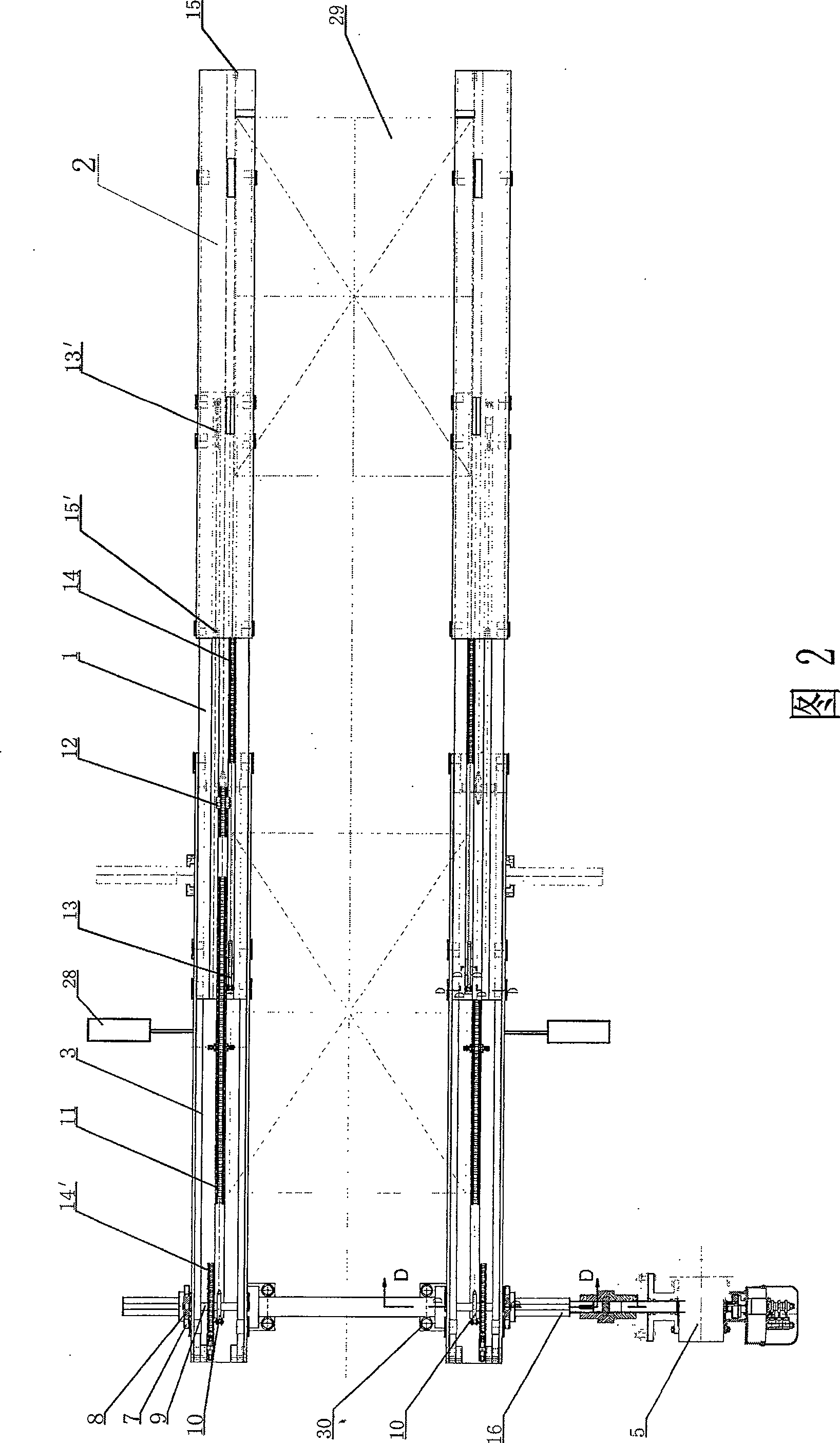

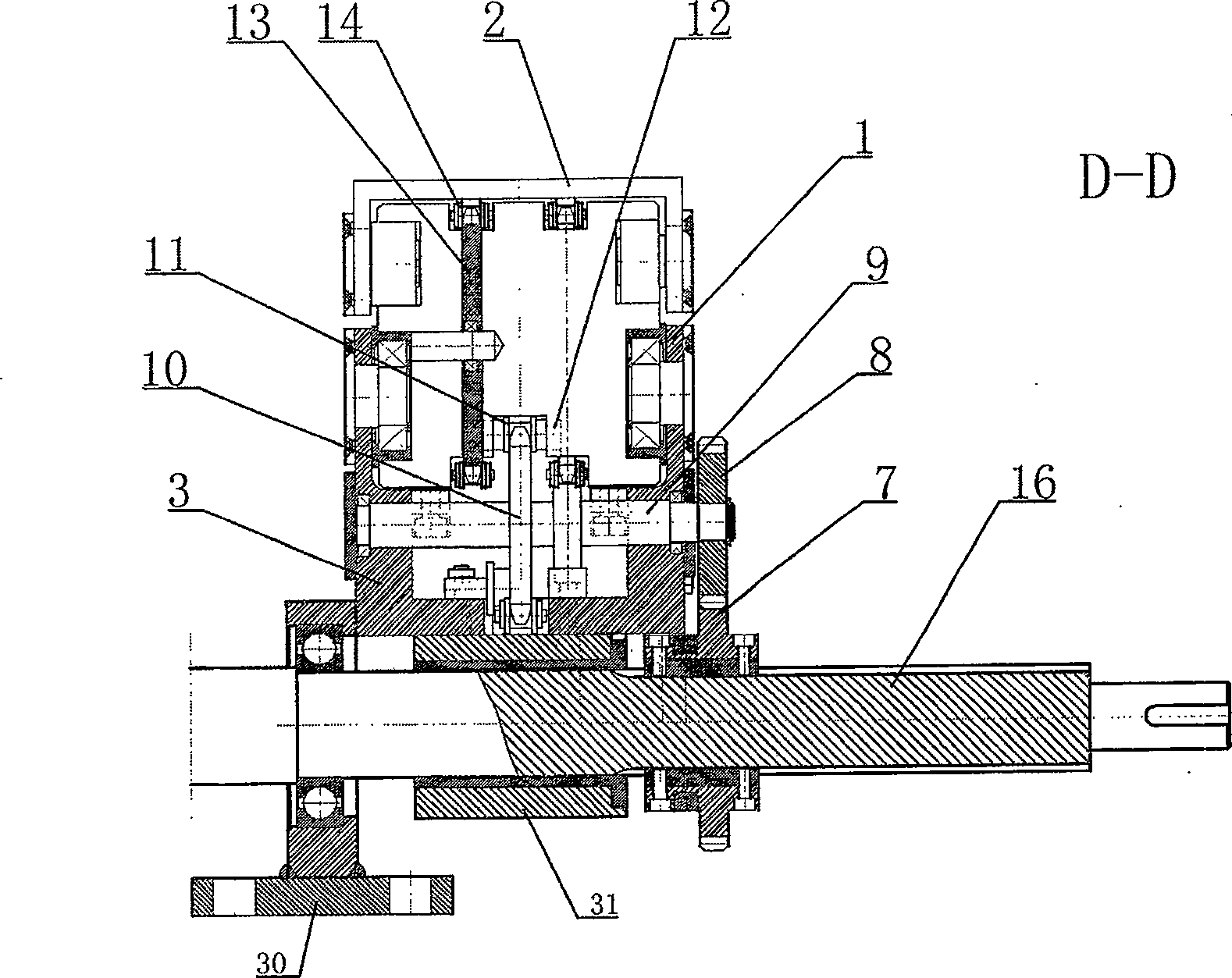

[0021] 1 to 7A, 7B and 7C, this embodiment of the present invention includes a ram 1, a ram seat 3, a slide plate 2 and a driving device, the ram 1 is slidably connected to the upper side of the ram seat 3, and the slide plate 2 is slidably connected to the upper side of the ram seat 3. On the upper side of the ram 1, a ram seat sprocket 10 is respectively installed at the two ends in the described ram seat 3, wherein one of the ram seat sprockets 10 is connected with the driving device through a transmission shaft 9; A ram drive chain 11 is installed between the two ram seat sprockets 10, and the ram drive chain 11 is connected with the ram 1 through a wedge 12. The ram seat sprocket 10, the ram driving chain 11 and the wedge 12 form the driving mechanism of the ram 1.

[0022] Front and rear ram sprockets 13' and 13 are installed at the front and rear ends of the ram 1 respectively, and a front and rear ram sprocket 13 are wound around the front of the front ram sprocket 13'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com