High-speed catch-release type parallel robot mechanism capable of realizing complete-turn rotation

A robot and high-speed technology, applied in the field of robots, can solve problems such as inertia asymmetry, large size of moving platform, stiffness, accuracy and acceleration asymmetry, and achieve good accuracy, high speed and acceleration capabilities, and large frame volume ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

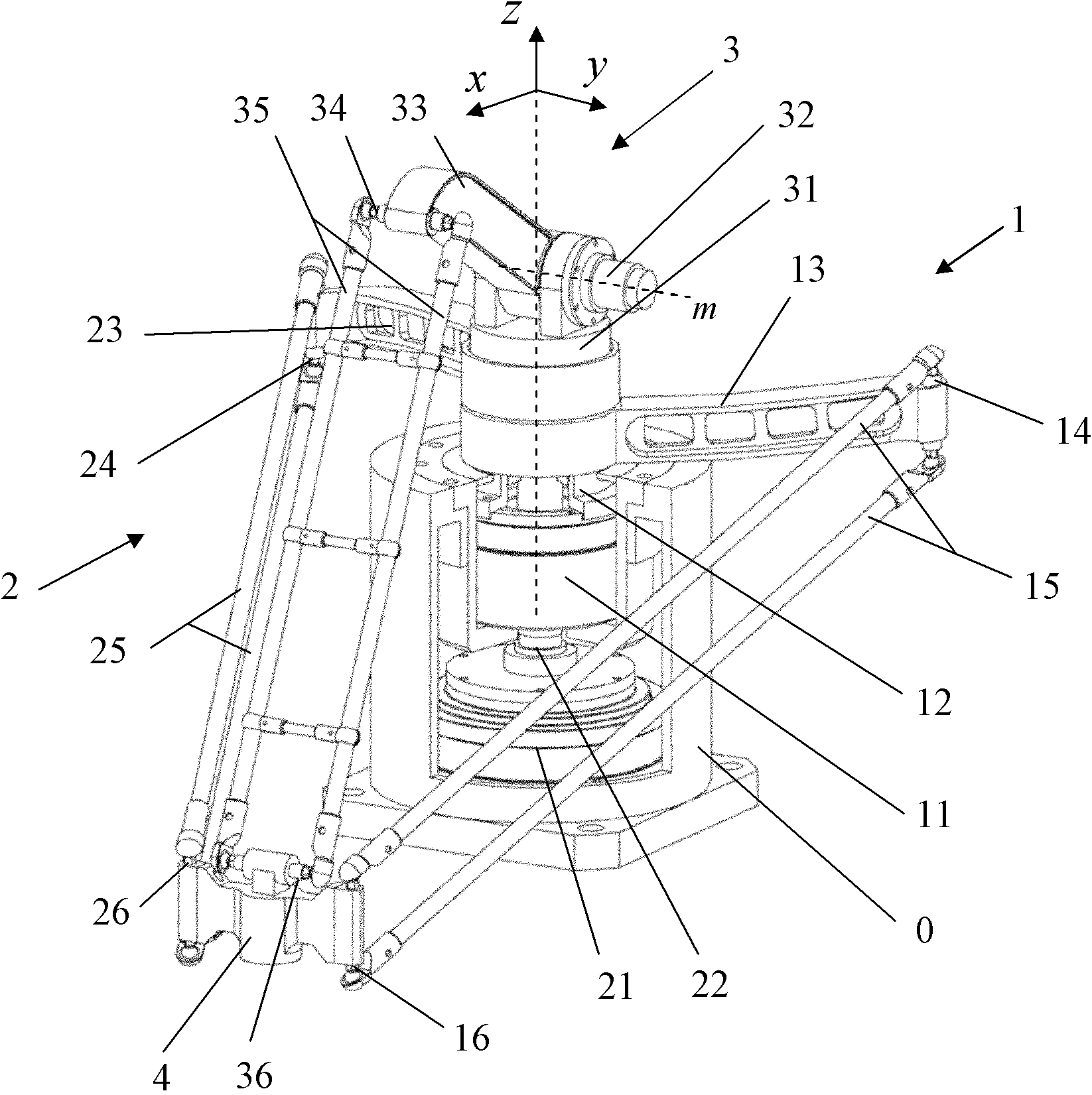

[0023] see Figure 1 ~ Figure 2 , a high-speed pick-and-place parallel robot mechanism capable of full rotation and three-dimensional translation. The mechanism includes a fixed frame 0, a moving platform 4, and a first branch chain 1 and a second branch chain connecting the fixed frame 0 and the moving platform 4. 2 and the third branch chain 3, the first branch chain 1 includes the first drive device 11, the first drive shaft 12, the first near-frame rod 13, the first near-frame connecting shaft 14, and two parallel first far-frame rods 15 and the first far frame connecting shaft 16, the first driving device 11 is fixedly arranged on the fixed frame 0, and its output end is fixedly connected with one end of the first driving shaft 12, the first driving device 11 and the first driving shaft 12 are both Hollow structure, the first drive shaft 12 can freely rotate around the axis z of the first drive shaft 12 relative to the fixed frame 0, the other end of the first drive shaft...

Embodiment 2

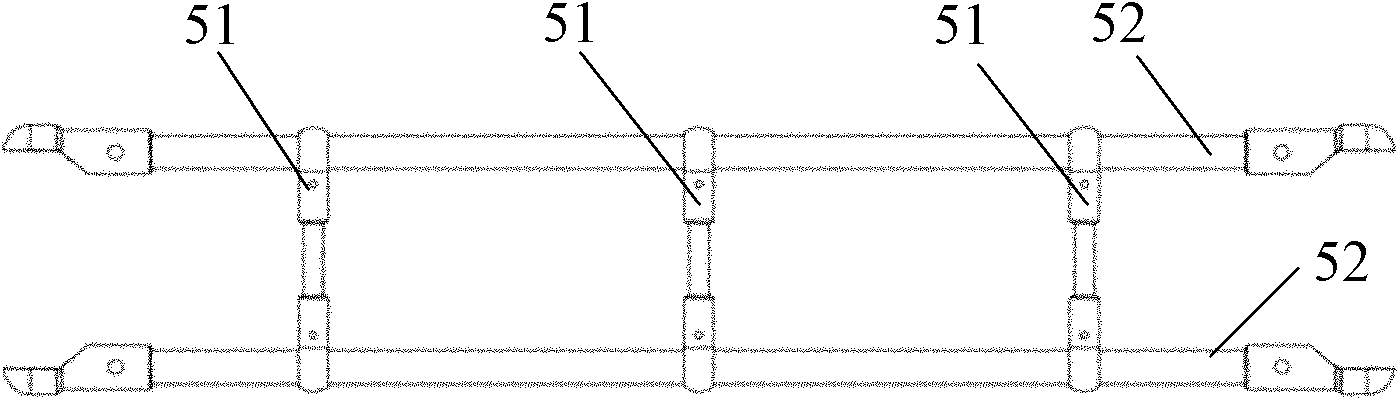

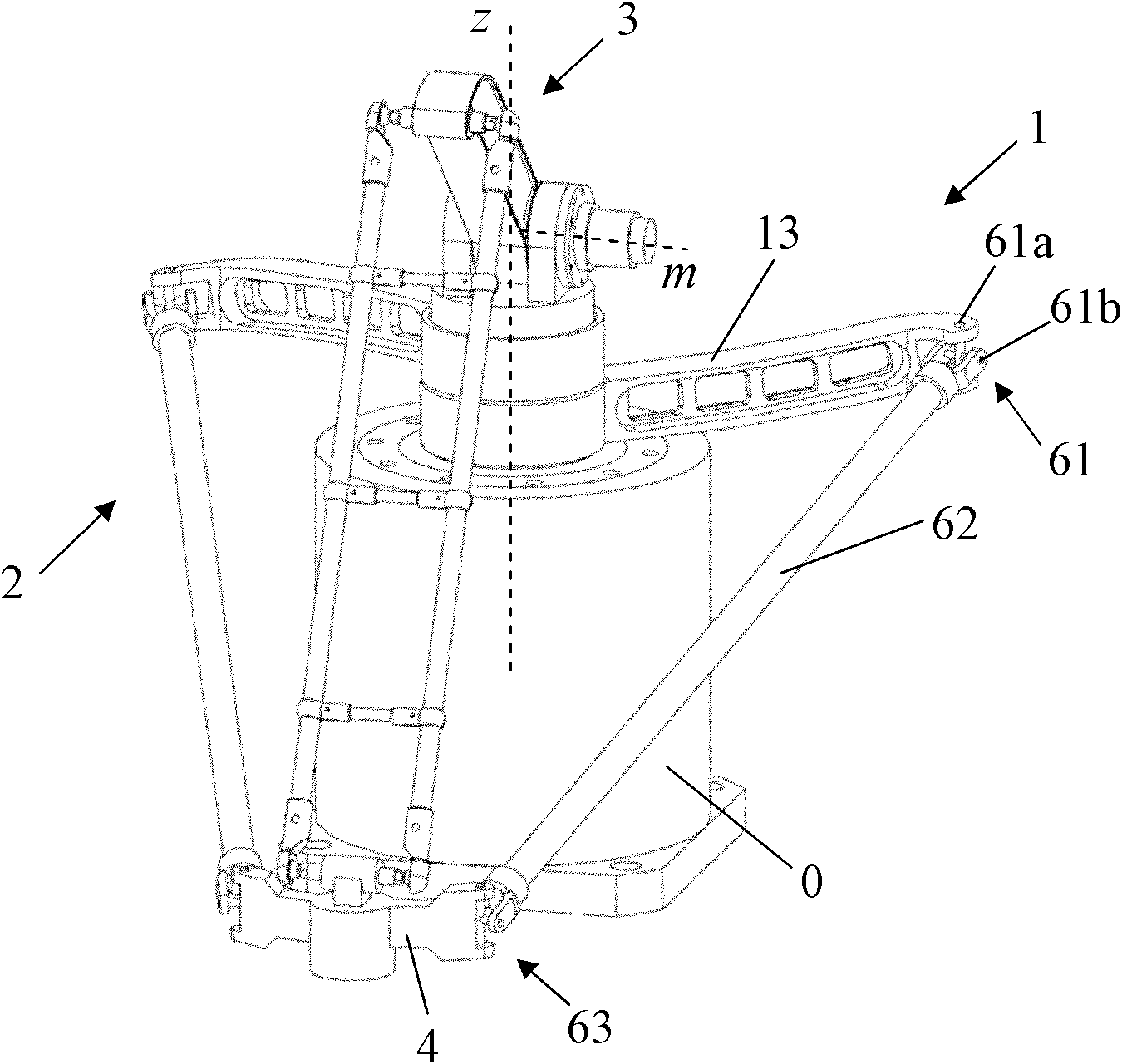

[0033] See Figure 3 ~ Figure 4 , a high-speed pick-and-place parallel robot mechanism that can realize full rotation and three-dimensional translation. The structure of the first and second remote support rods adopts a single rod structure. At this time, both ends of the remote support rod need to have two The Hooke hinges with four orthogonal rotational degrees of freedom are respectively hinged to the near-frame bar and the moving platform of the corresponding branch chain. In the first branch chain, the first near frame rod 13 is hinged with the first far frame rod 62 through the Hooke hinge 61, so that the first far frame rod 62 has two orthogonal angles relative to the first near frame rod 61. Degree of freedom of rotation, the Hooke hinge 61 is composed of a vertical hinge axis 61a and a horizontal hinge axis 61b, the axis of the vertical hinge axis 61a is parallel to the z-axis, the axis of the horizontal hinge axis 61b is perpendicular to the axis of the plumb hinge a...

Embodiment 3

[0036] See Figure 5, a high-speed pick-and-place parallel robot mechanism that can realize full-cycle rotation and three-dimensional translation, the third far frame rod uses a single rod structure, and the third near frame rod 33 of the third branch chain is connected to the first rod through the hinge shaft 71 The three far frame rods 72 are hinged, so that the third far frame rod 72 has a degree of freedom of rotation relative to the third near frame rod 33, the axis of the hinge shaft 71 is parallel to the m axis, and the third far frame rod 72 is connected to the third far frame rod 73 through the hinge shaft 73. The moving platform 4 is hinged, so that the moving platform 4 has a rotational degree of freedom relative to the third remote frame rod 72, and the axis of the hinge shaft 73 is also parallel to the m-axis. The connection mode of the first branch chain 1, the second branch chain 2 and other parts can be the same as that of embodiment 1, and also can be the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com