Multi-degree-of-freedom four-track counterweight trolley synchronous control system and control method

A technology of synchronous control and counterweight trolley, which is applied to non-deflectable wheel steering, vehicle components, steering mechanisms, etc., can solve the problems of high price, high mechanical performance requirements, and large loss, so as to reduce the overall weight and ensure synchronization Effect of controlling precision and reducing stress load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

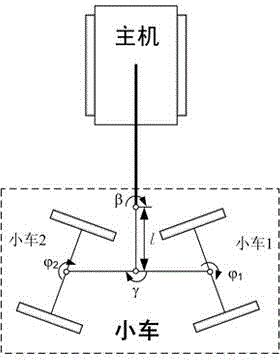

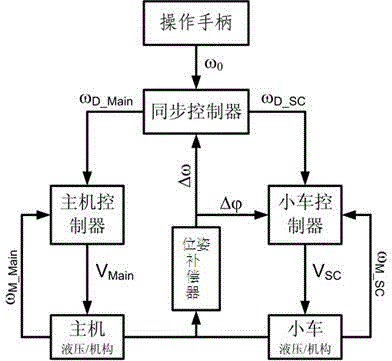

[0053] In the present invention, the crawler crane (hereinafter referred to as the main engine) is equipped with a super-lifting counterweight trolley (hereinafter referred to as the trolley), which is equipped with two left and right crawler mechanisms that can independently rotate around its own axis of rotation. The two crawler mechanisms They are referred to as trolley 1 and trolley 2 for short, and the specific structural block diagram is as follows figure 1 shown. It can be seen from the figure that the main engine is connected to the trolley through a telescopic two-link mechanism. In the above structure, the whole system provides three degrees of freedom in pose and orientation, namely the rotation angles β and g, and the telescopic length l of the two linkages. Among them, the first set of crawler mechanism trolley 1 and the second set of crawler m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com