Assembly method after disassembling general assembly of four doors of automobile

An assembly method, four-door technology, applied in the field of body-in-white four-door matching process, to achieve the effect of saving investment and implementation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

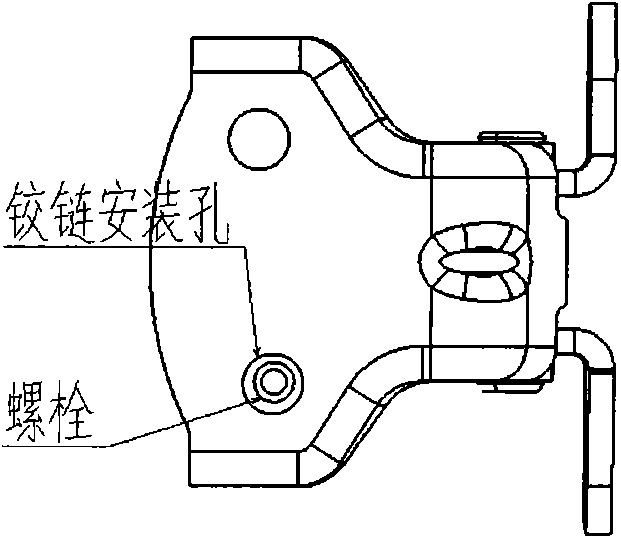

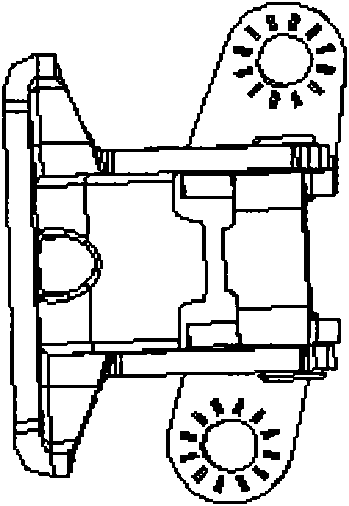

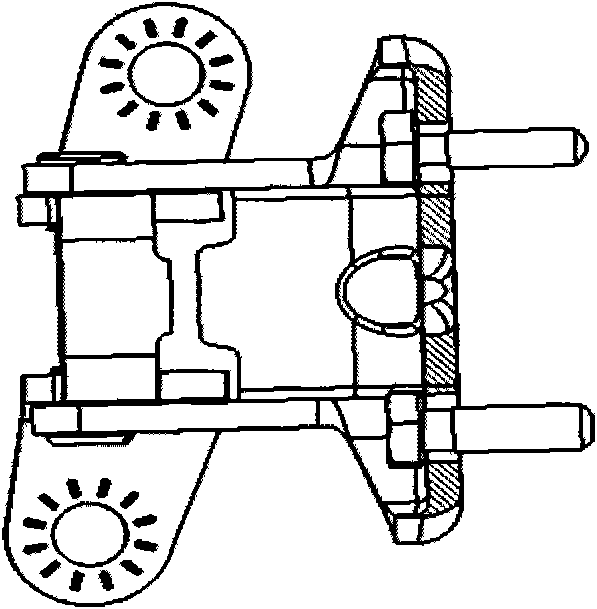

[0029] Refer to attached figure 1 , 2. It is an existing newly developed model, and the hinge is a part of the original platform model. According to the requirements of the final assembly process, the four doors of the new model will be assembled separately after the final assembly and disassembly. The original hinges are stamped hinges, and the four mounting holes are through holes or oblong holes, leaving adjustment margins to absorb the tolerances of the door assembly and ensure the flatness and clearance of the four doors when they are matched.

[0030] After this kind of hinge is assembled on the welding adjustment line, if it is dismantled in the final assembly, it still needs to be adjusted when the four doors are reassembled, and after assembling the door inner panel and other co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com