Moment and speed sensor of electric bicycle

A technology of electric bicycles and speed sensors, which is applied in the direction of instruments, torque measurement, vehicle components, etc., can solve the problems of complex structure, no output, easy winding of sensor lead wires, etc., and achieve good signal transmission stability and measurement sensitivity High, the effect of improving work performance and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

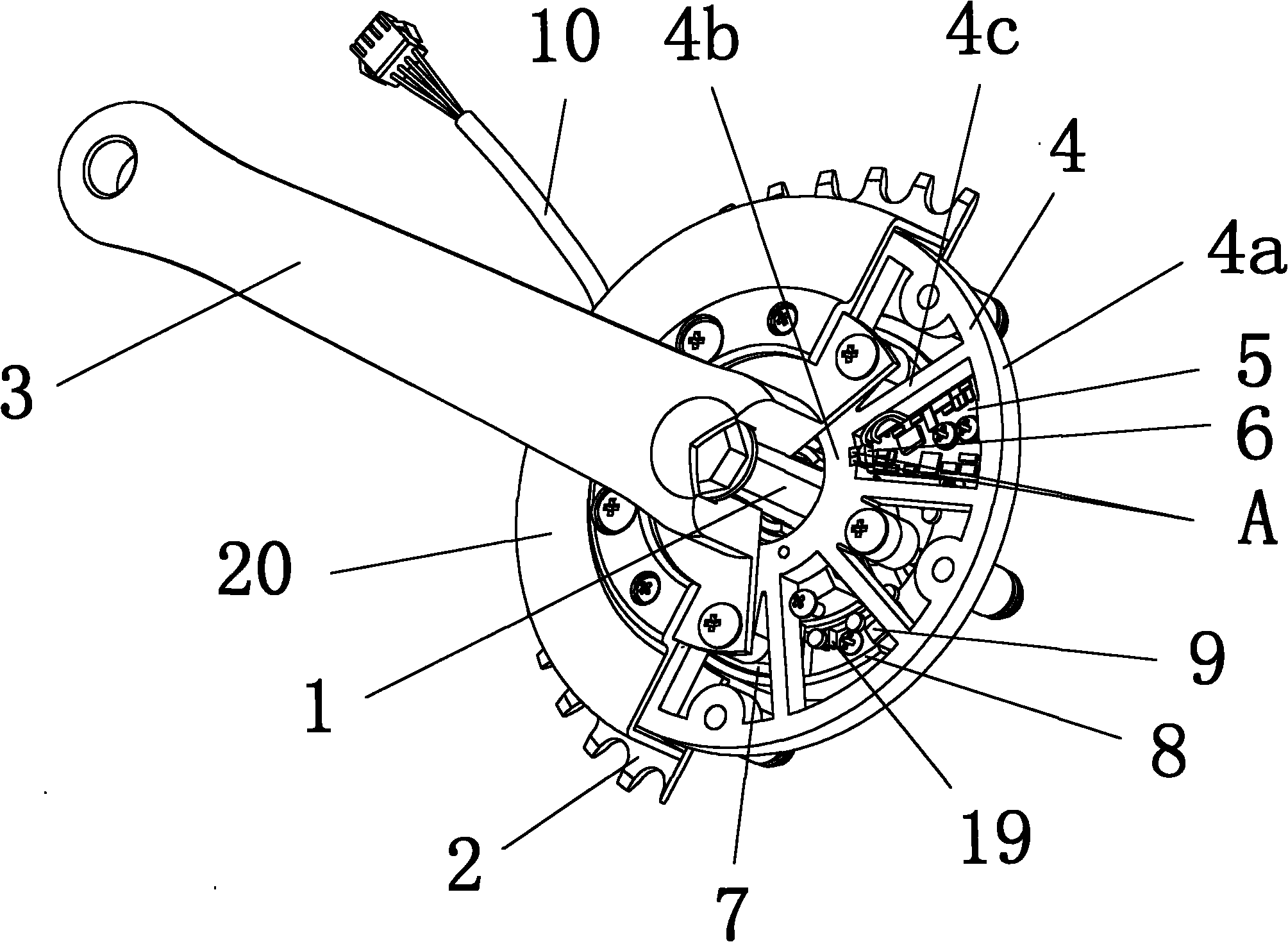

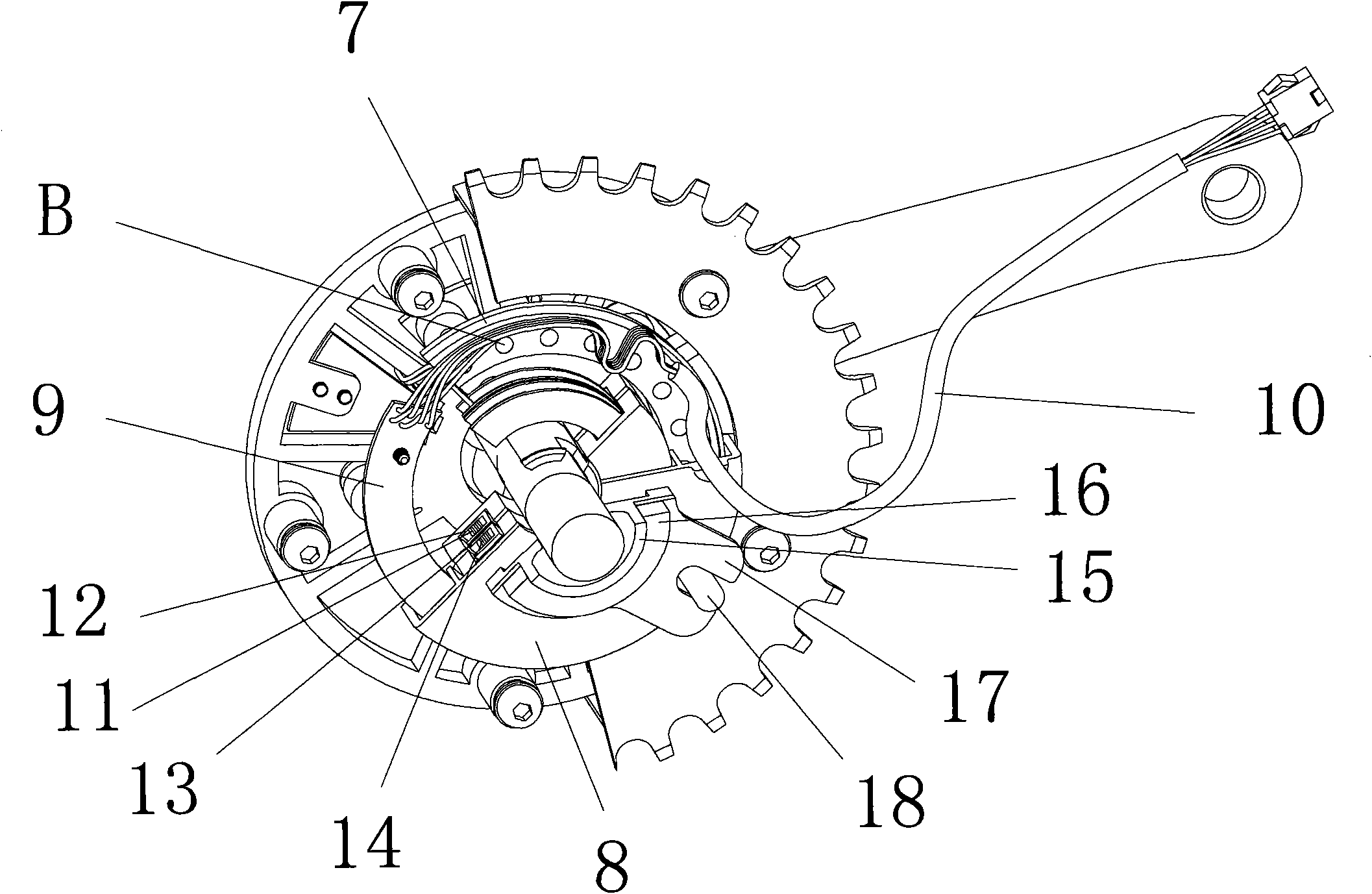

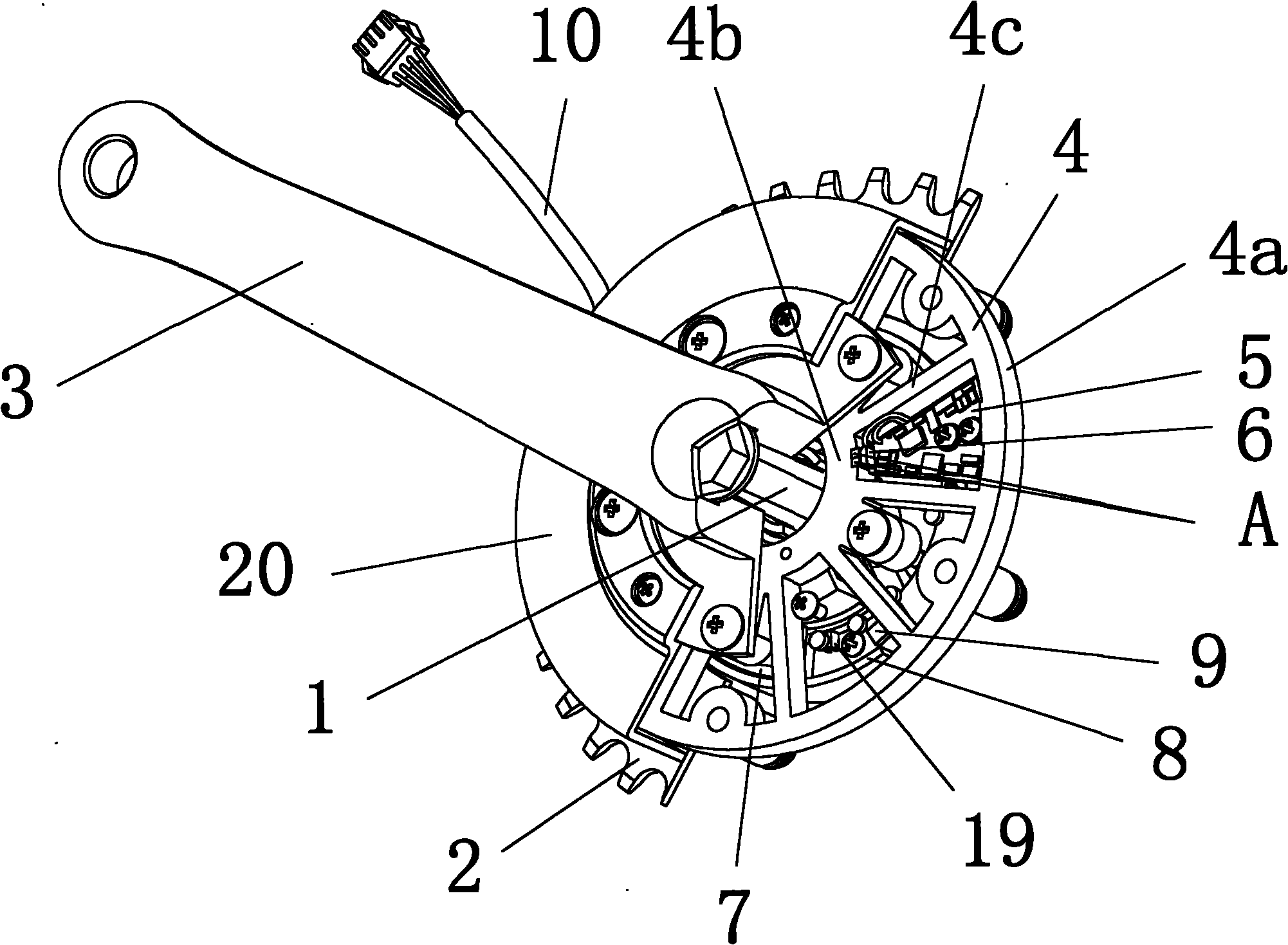

[0022] Example: Combine figure 1 , figure 2 As shown, the electric bicycle torque and speed sensor provided by the present embodiment consists of a central shaft 1, a tooth plate 2, a crank 3 fixed on the central shaft 1, a deformation frame 4, a signal output plate 5, a linear Hall element 6, Rotating part 7, stationary part 8, signal receiving plate 9, lead wire 10, rotating magnetic pot 11, rotating coil 12, stationary magnetic pot 13, stationary coil 14, central axis bowl 15, central joint 16, stop-rotating piece 17, stop The rotary rod 18, the switch Hall element 19 and the protective cover 20 are formed together.

[0023] In the present embodiment, the deformation frame 4 is composed of an outer ring 4a, an inner ring 4b and 10 connecting ribs 4c that are radially connected between the inner ring and the outer ring ( figure 1 Only half of the deformation frame 4) is shown in the figure, in which the inner ring 4b and the crank 3 are fastened by screws, and the outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com