Torque and speed sensor for electric bicycle

A technology of electric bicycles and speed sensors, which is applied to vehicle components, rider driving, transportation and packaging, etc. It can solve the problems of inability to achieve human-machine coordination, inability to output, complex structure, etc., to improve work performance and measurement accuracy , stable signal transmission and high measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

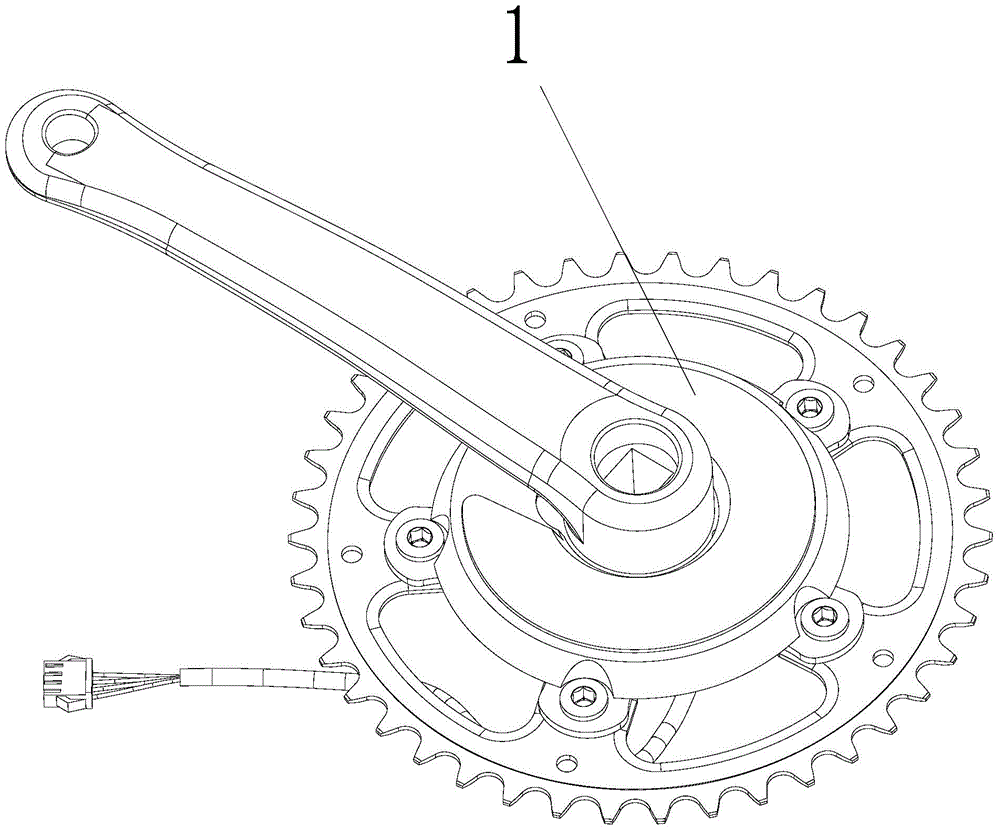

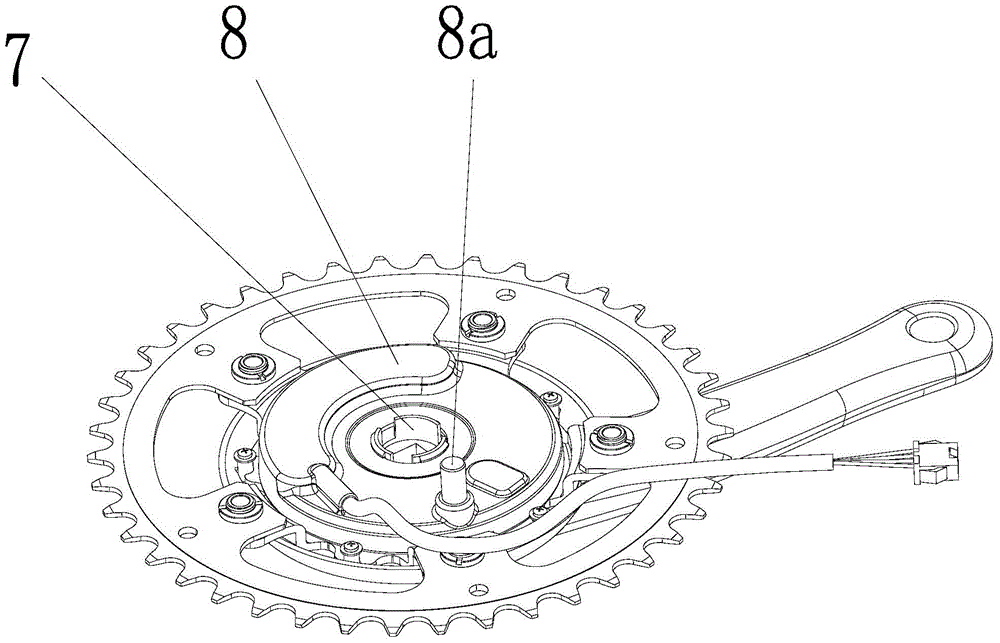

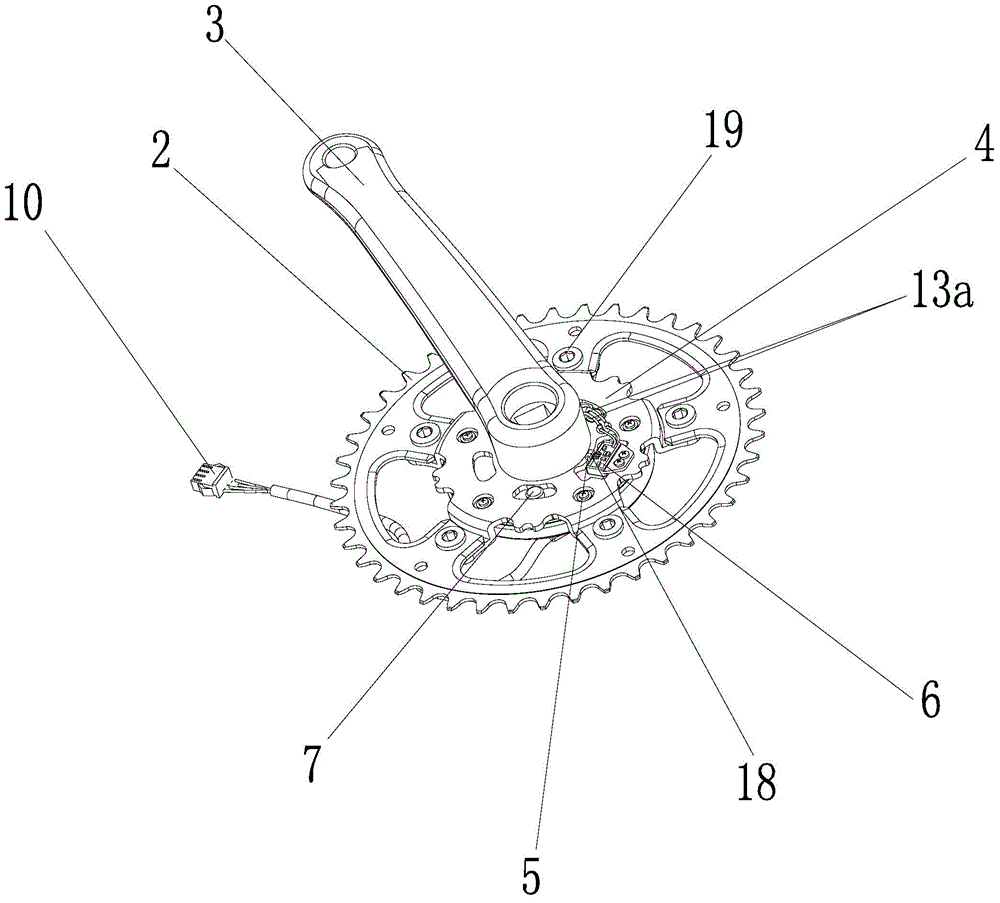

[0033] Figure 1 to Figure 9 A specific embodiment of the moment and the speed sensor of this electric bicycle of the present invention is shown, and it comprises crankshaft 2, crank 3 and deformation frame 4, and wherein deformation frame 4 is made of coaxially arranged outer ring 4a and inner ring 4b, And five connecting ribs 4c distributed radially and connected between the outer ring 4a and the inner ring 4b.

[0034] refer to image 3 and Figure 4 As shown, the deformable frame 4 is stamped from a metal material, and its inner ring 4b has a central tooth hole 4g, and the crank 3 is riveted and fixed in the central tooth hole 4g, so that the crank 3 and the inner ring 4b are fixed. The outer ring 4a is provided with five crankset installation holes 4e distributed in a circular shape, and the crankset 2 is connected to the five crankset installation holes 4e with special fasteners 19, so that the crankset 2 and the outer ring 4a phase fixed.

[0035] In actual applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com