Hub motor with torque sensing function and electric bicycle adopting motor

A wheel hub motor and torque technology, applied in the field of electric bicycles, can solve problems such as unsatisfactory use effect, unstable performance, unreasonable design, etc., and achieve the effect of man-machine coordination, high measurement sensitivity, and good signal transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

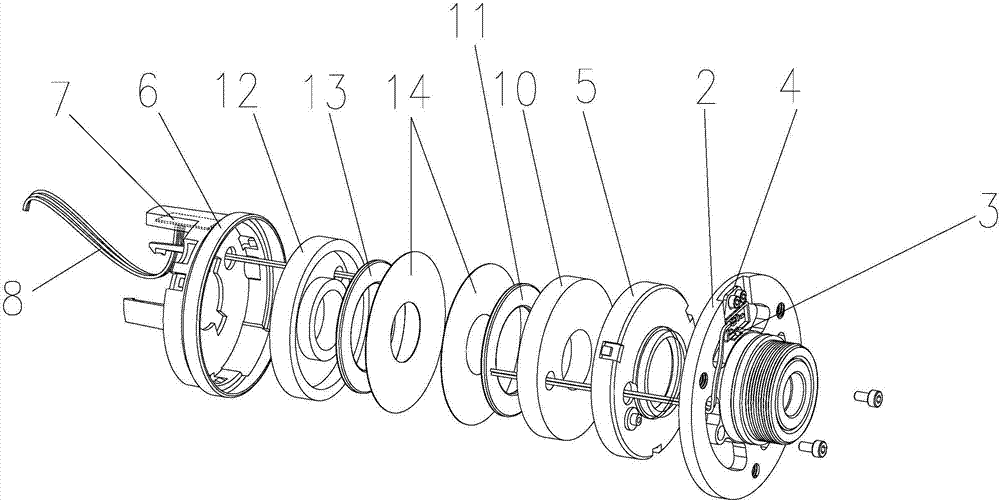

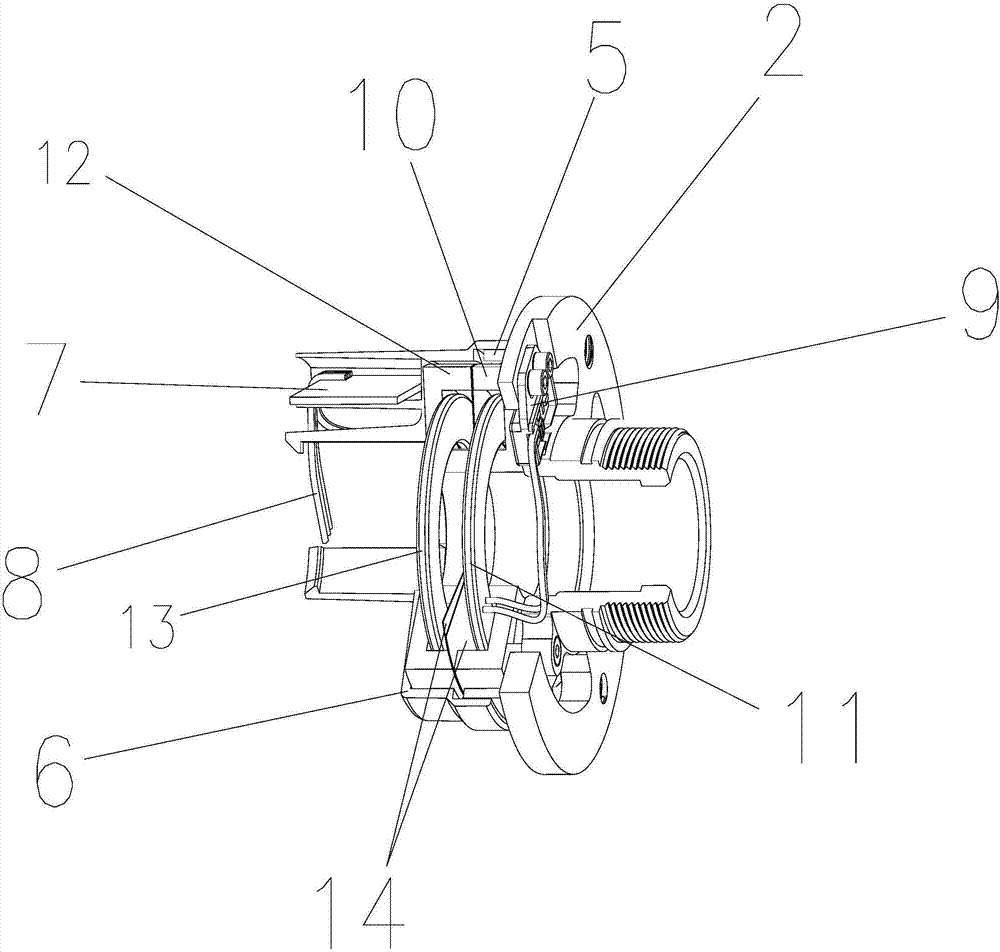

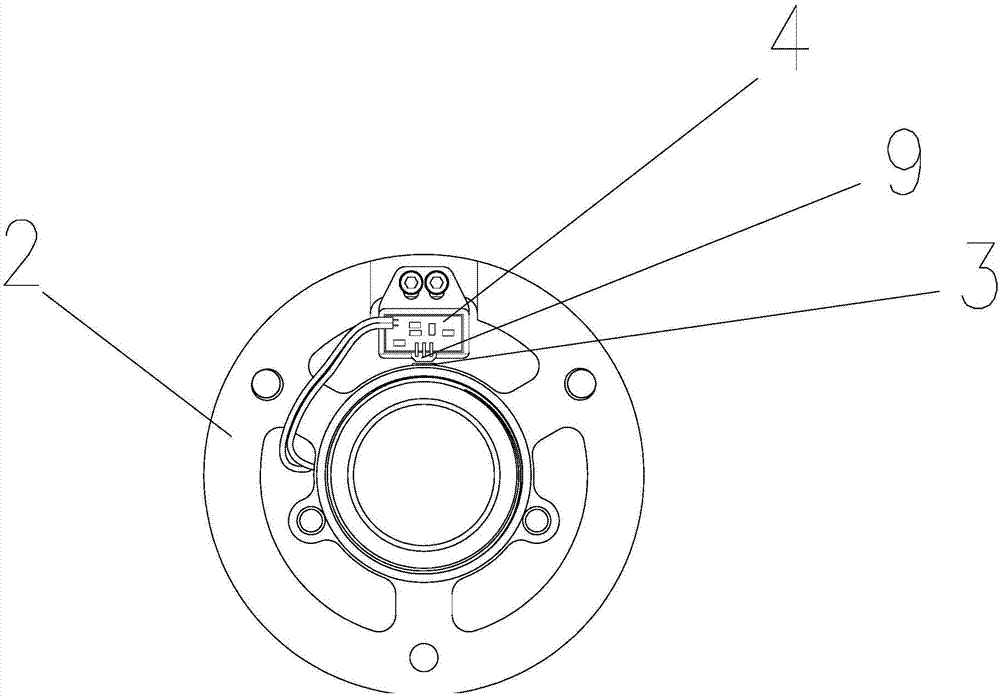

[0031] Figure 1 ~ Figure 3 A preferred embodiment of the hub motor with torque sensing function of the present invention is shown, which includes a hub 1, a motor core and a drive hub 2, wherein the motor core is arranged inside the hub, and the drive hub 2 and the hub 1 coaxial fixed.

[0032] During practical application, the wheel hub 1 is installed on the rear wheel of the bicycle, which is rotatably connected to the bicycle frame, and the flywheel of the bicycle is coaxially fixed on the drive shaft sleeve 2 . Hub 1 is made of figure 1 The hub shell 1a and the hub right end cover 1b are locked and fixed together by six screws. In the electric mode, the motor core is energized to drive the wheel hub 1 to rotate, thereby driving the vehicle forward; in the human riding mode, the rider steps on the crank to drive the crankset to rotate through the chain, and the crankset drives the hub 1 through the drive bushing 2 Rotate, and then drive the vehicle to move forward.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com