Method for preparing hydrogen gas by taking marsh gas as raw material

A raw material and biogas technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of high production cost and complicated process, and achieve the effect of cost reduction, simple process and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

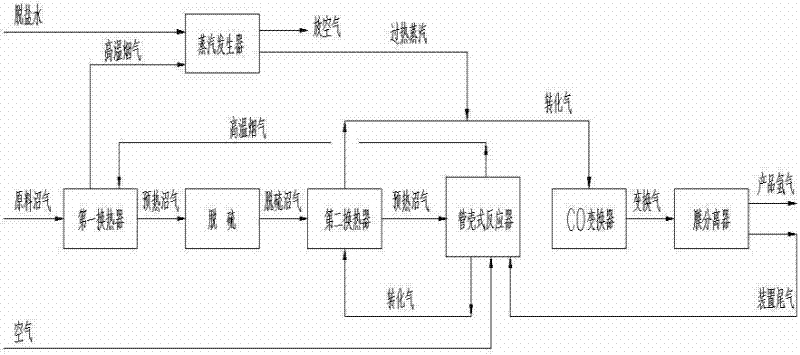

[0024] Embodiment 1: as figure 1 Shown in-3, a kind of method using biogas as raw material to prepare hydrogen comprises the following steps:

[0025] A. At room temperature, the raw material biogas with a pressure of 1.2Mpa (G) is heated to 340-360°C by the first heat exchanger, and then enters the desulfurization reactor for desulfurization. The total sulfur content in the gas is controlled at 20mg / m 3 the following;

[0026] B. After the desulfurized gas is heated to 580-600°C by the second heat exchanger, it enters the tube side of the shell-and-tube reactor. 2 o 3 Carry out reforming reaction under the action of catalyst;

[0027] C. The gas obtained in step B is sent to the CO converter to react with the superheated steam after being heat-exchanged by the second heat exchanger, and the gas obtained by the reaction is sent to the membrane separator for separation, and the product hydrogen and the tail gas of the device are obtained by separation ;

[0028] D, the dev...

Embodiment 2

[0032] Embodiment 2: as figure 1 Shown in-3, a kind of method using biogas as raw material to prepare hydrogen comprises the following steps:

[0033]A. At room temperature, the raw material biogas with a pressure of 1.2Mpa (G) is heated to 340-360°C by the first heat exchanger, and then enters the desulfurization reactor for desulfurization. The total sulfur content in the gas is controlled at 20mg / m 3 the following;

[0034] B. After the desulfurized gas is heated to 580-600°C by the second heat exchanger, it enters the tube side of the shell-and-tube reactor, and undergoes reforming reaction under the action of Ni / SBA-15 catalyst;

[0035] C. The gas obtained in step B is sent to the CO converter to react with the superheated steam after being heat-exchanged by the second heat exchanger, and the gas obtained by the reaction is sent to the membrane separator for separation, and the product hydrogen and the tail gas of the device are obtained by separation ;

[0036] D, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com