Device and method for fixing track plate and cement emulsified asphalt slurry template

A technology of cement emulsified asphalt and fixing method, which is applied in the directions of track, track laying, track maintenance, etc., can solve the problems of influence of steel insulation, influence on concrete base, time-consuming and labor-intensive, etc., so as to ensure the pull-out resistance and save the embedded parts. Demolition work process and cavity grouting sealing work process, the effect of improving anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

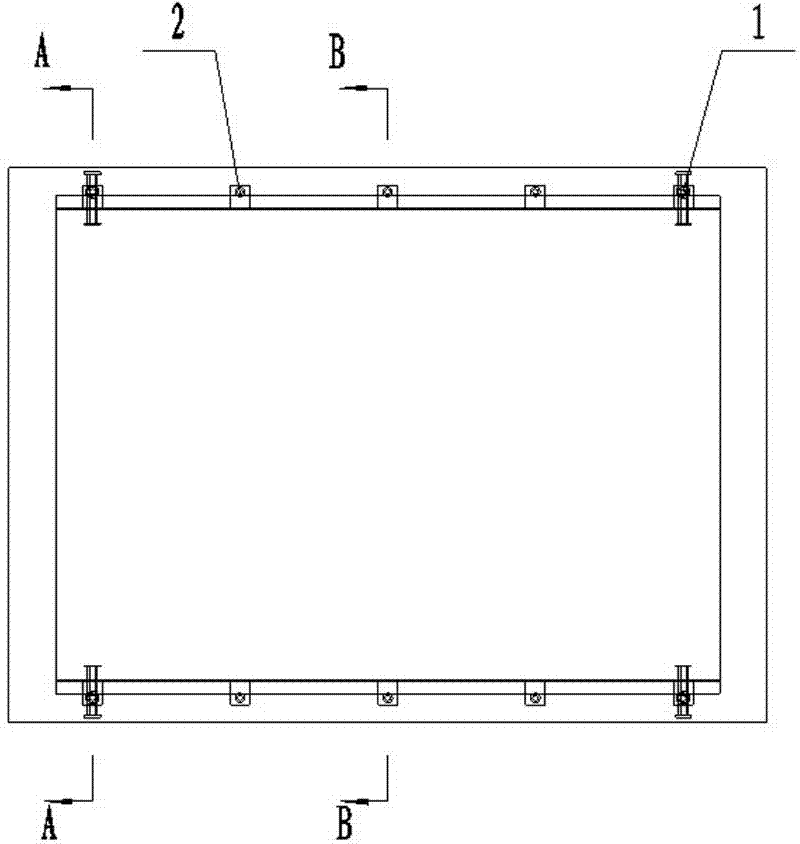

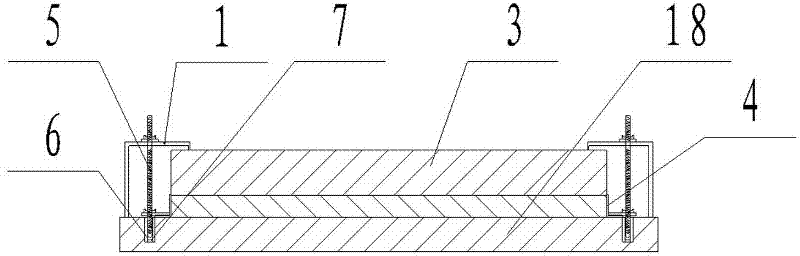

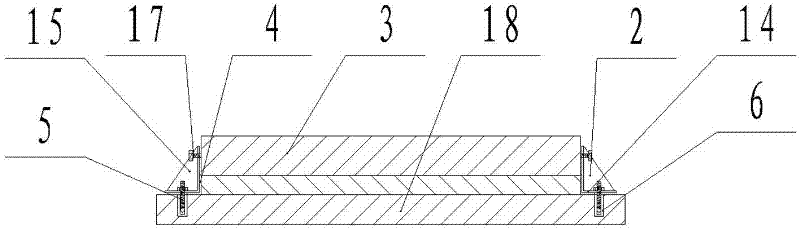

[0023] The fixing device for the track slab and the cement emulsified asphalt mortar formwork includes a number of track plate pressing parts 1 and formwork fixing parts 2 as well as screw rods 5 respectively threaded on the two. The screw rods 5 are screwed on the upper end face to be flush with the upper surface of the concrete base On the insulating sleeve 6, a lower end cover 7 is fixed at the lower end of the insulating sleeve 6, the outer cylindrical surface of the insulating sleeve 6 is threaded, and the outer cylindrical surface of the insulating sleeve 6 is fixed with a non-slip strip 8. The rail plate pressing member 1 includes two horizontally placed pressing channels 9 with a vertical gap between the waists. The front end of the pressing channel 9 is fixed with a lower pressing plate 10 whose lower end is lower than its lower end, and the pressing groove The back end of the steel 9 is provided with a vertically placed support channel 11, the upper waist of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com