Light-section mud shield powder fine sand layer receiving method

A receiving method and technology of shield powder, which can be used in earth-moving drilling, mining equipment, tunnels, etc., and can solve problems such as bad social impact, water and sand gushing, and ground subsidence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

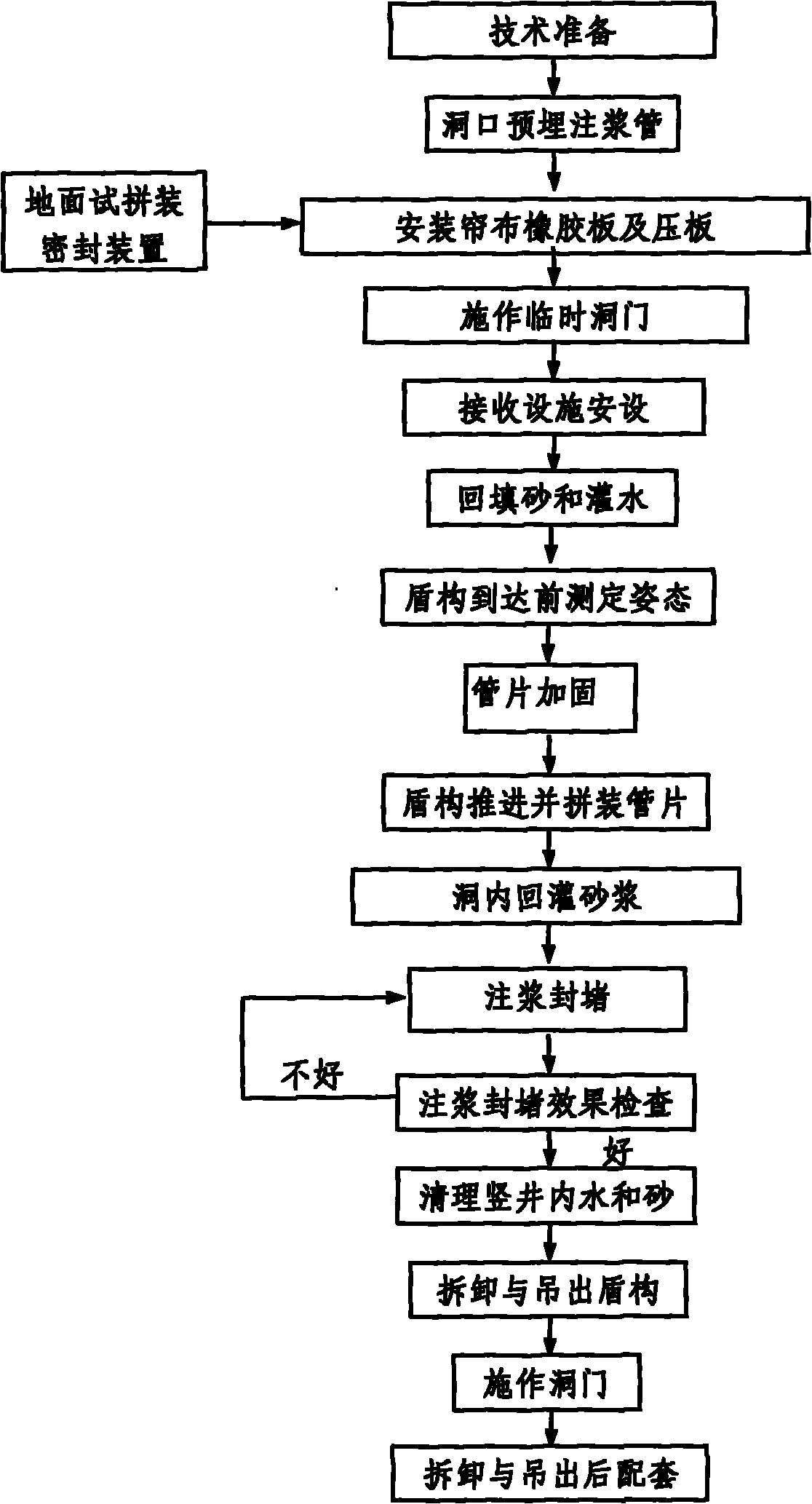

[0034] 1. Technical preparation

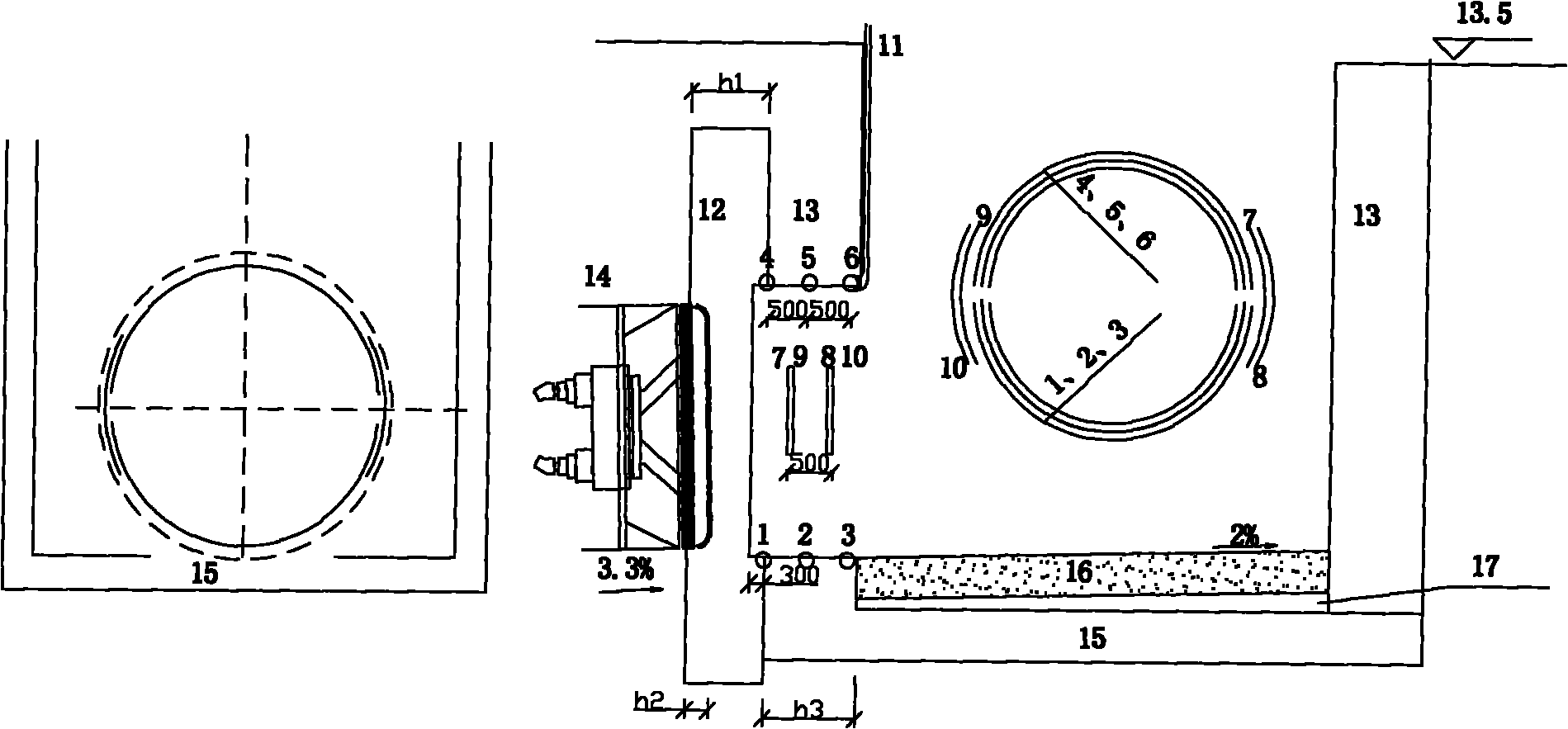

[0035] 1. On the basis of maintaining the balance of water and soil pressure inside and outside the well, simulate the situation when the shield machine is excavating down the river to carry out the design of sand filling and irrigation, so as to ensure that there is no water and sand gushing during the breakthrough.

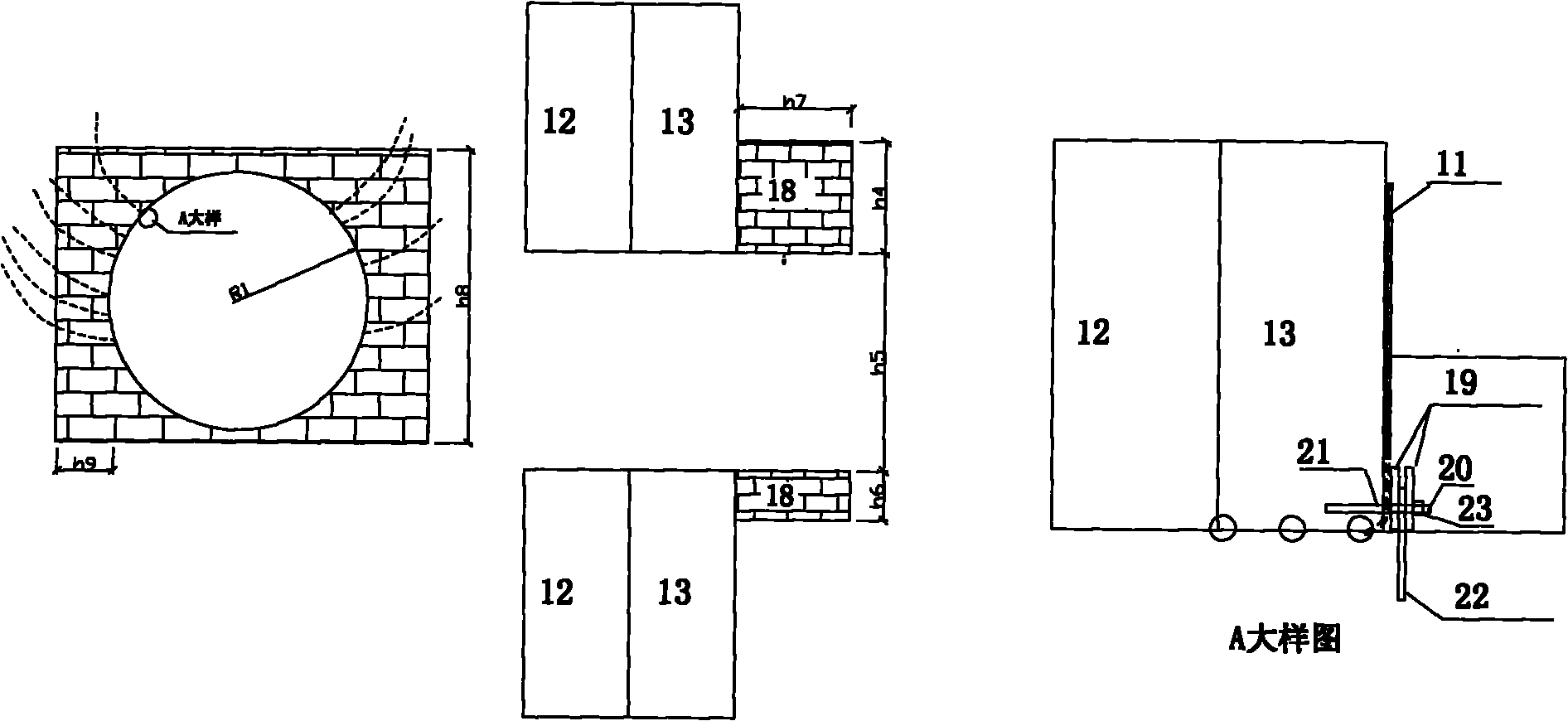

[0036] 2. In order to enable the shield machine to smoothly cut the diaphragm wall, reduce the shield propulsion resistance, and facilitate the position determination of the shield machine, the diaphragm wall within the opening range can be chiseled manually or by other means. The length of the continuous wall is determined based on the purpose of achieving smooth cutting of the shield, reducing the resistance of the shield to advance, and facilitating the determination of the position of the shield. In this embodiment, the length of the continuous wall is 30 cm.

[0037] 3. After the cutterhead cuts into the continuous wall fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com