Heat exchange device

A technology of heat exchange device and micro-channel heat exchanger, which is applied in the directions of household heating, heating mode, household heating, etc., can solve the problems of unreasonable combination structure setting, long flow distance of condensate water, and obstruction of air circulation, etc. Improve drainage performance, reasonable design of air duct flow path, and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

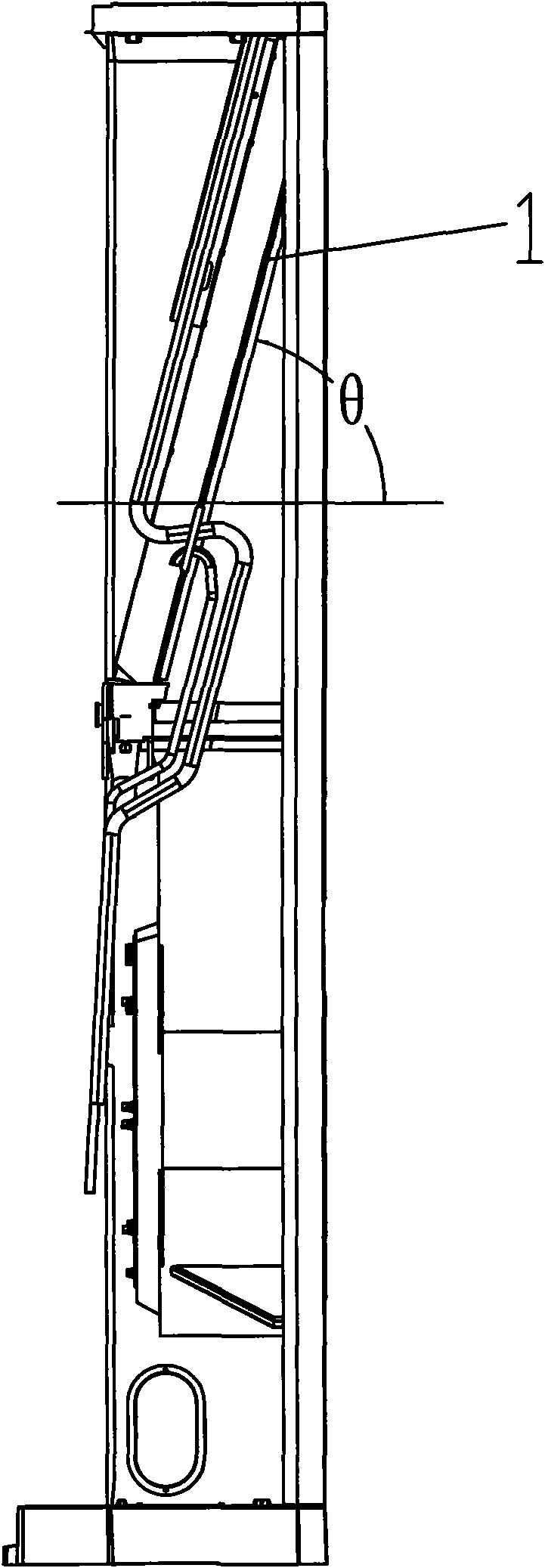

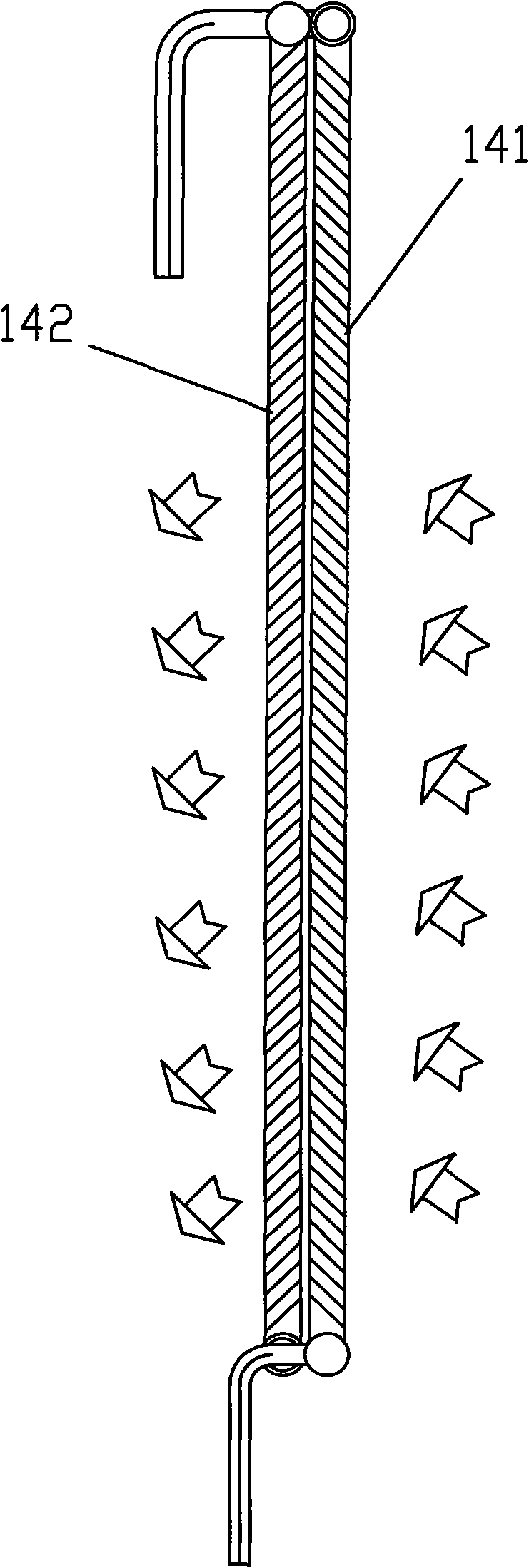

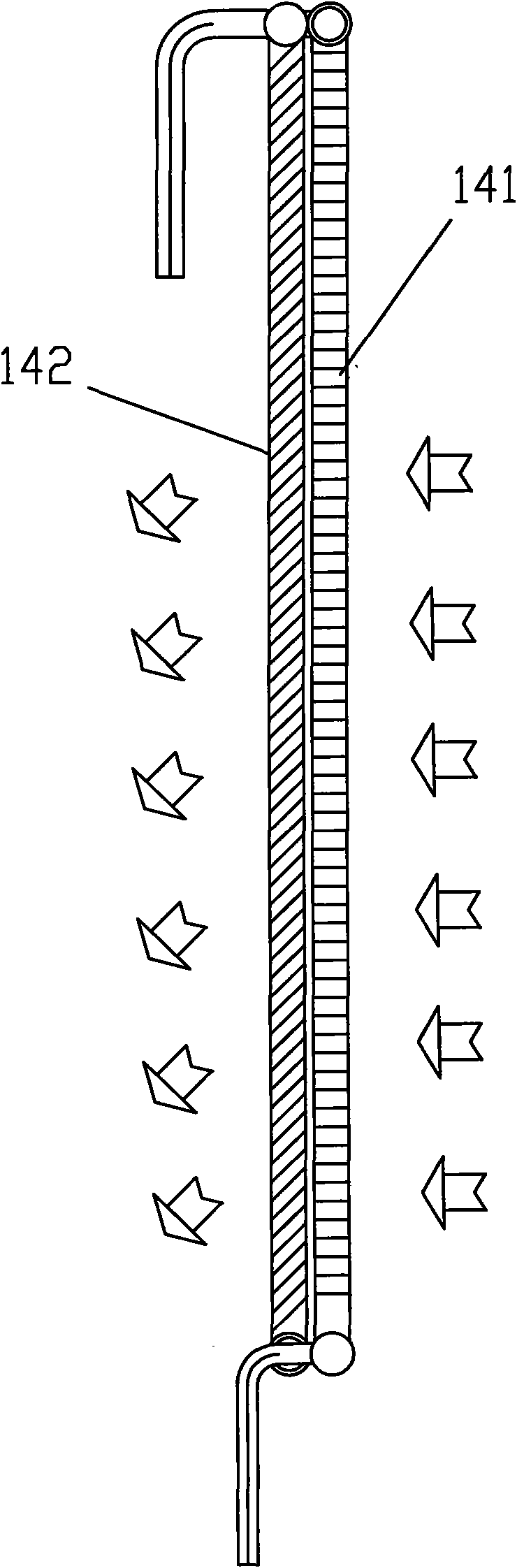

[0036] Such as figure 1 As shown, a heat exchange device is applied to a heat exchanger of an indoor unit or an outdoor unit of a cabinet air conditioner, such as an evaporator. It includes at least one microchannel heat exchanger 1 . See figure 1 , the microchannel heat exchanger arranged inside the indoor unit of the cabinet air conditioner forms an included angle θ with the horizontal direction, 30°≤θ≤90°. combine Figure 8 It can be seen that the microchannel heat exchanger 1 generally includes a first header 11, a second header 12 arranged in parallel with a certain distance from the first header 11, and a second header connected between the first header 11 and the second header. Among the flow tubes 12 are several flat tubes 13 spaced at a certain distance from each other and several fins 14 respectively arranged bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com