Method for correcting image sensor

An image sensor, pixel technology, applied in instruments, data processing input/output process, electrical digital data processing and other directions, can solve problems such as signal strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

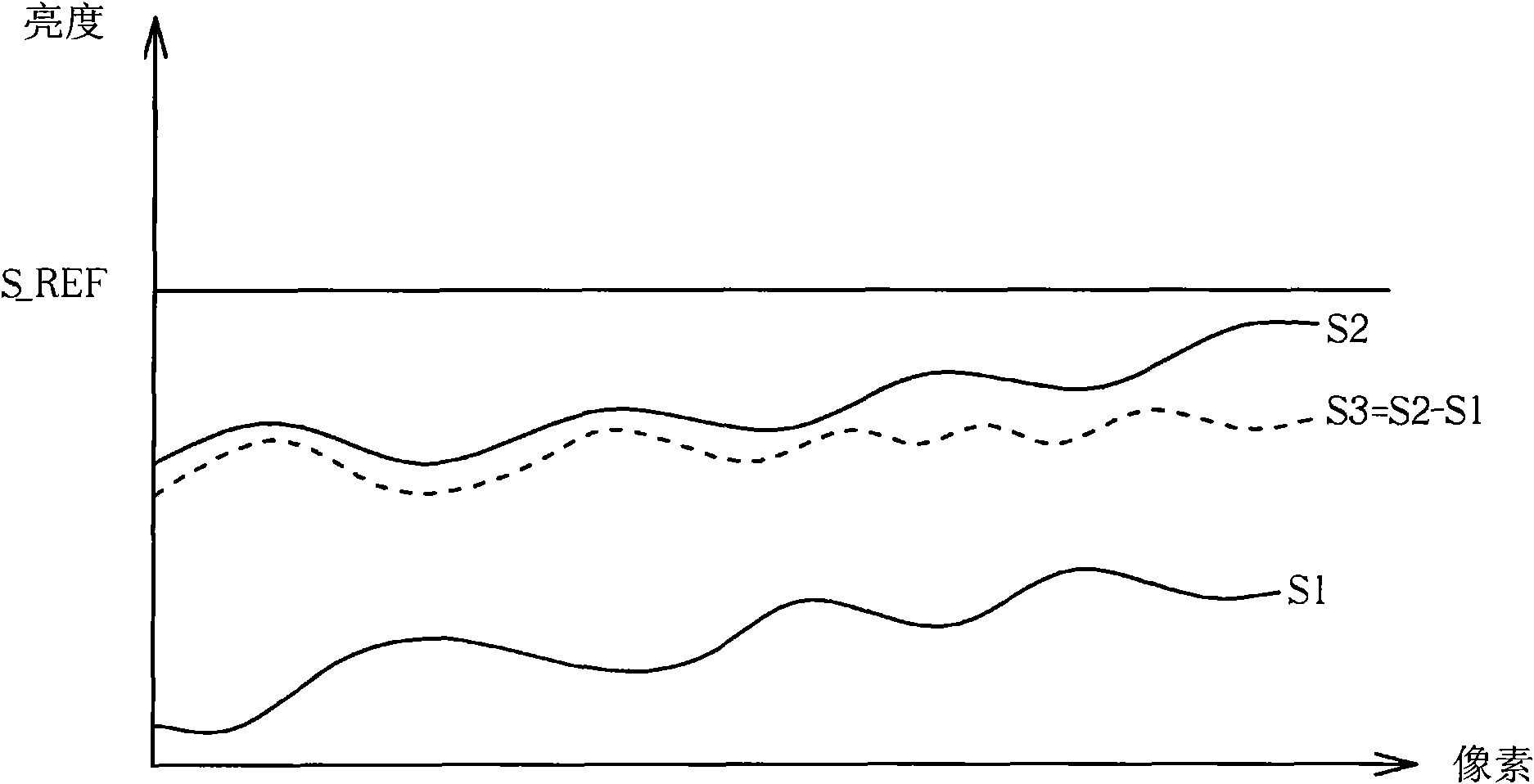

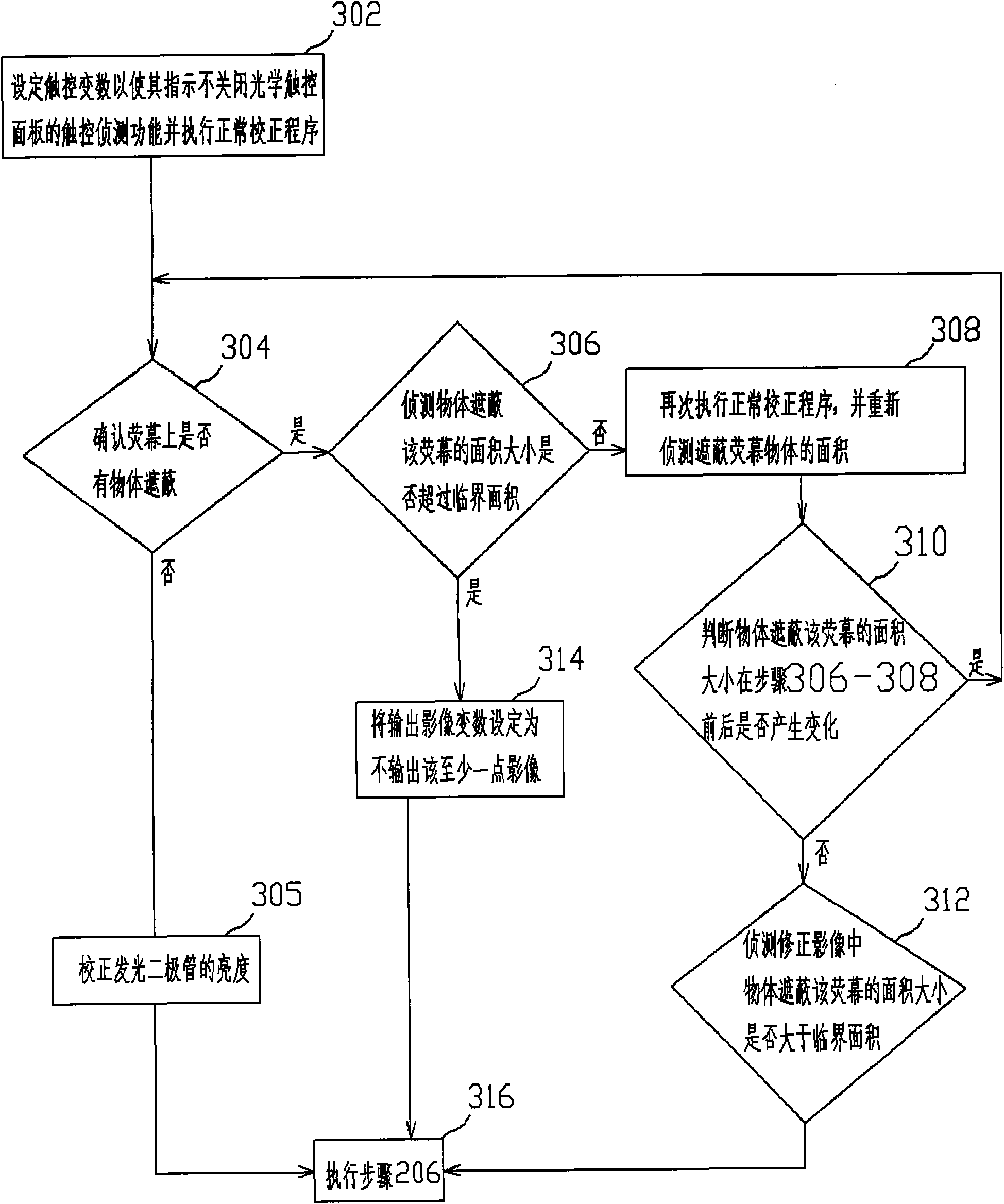

[0024] The invention discloses a method for calibrating an image sensor. In this method, when the image sensor is turned on, it is first calibrated according to specific conditions, and after the image sensor is turned on, at regular intervals, a part of the frame originally scheduled for image processing is intercepted. The brightness magnification ratio of the group is calibrated so as to make the image sensor operate correctly in response to any environmental changes that may occur during the operation of the image sensor without affecting the general operation of the image sensor.

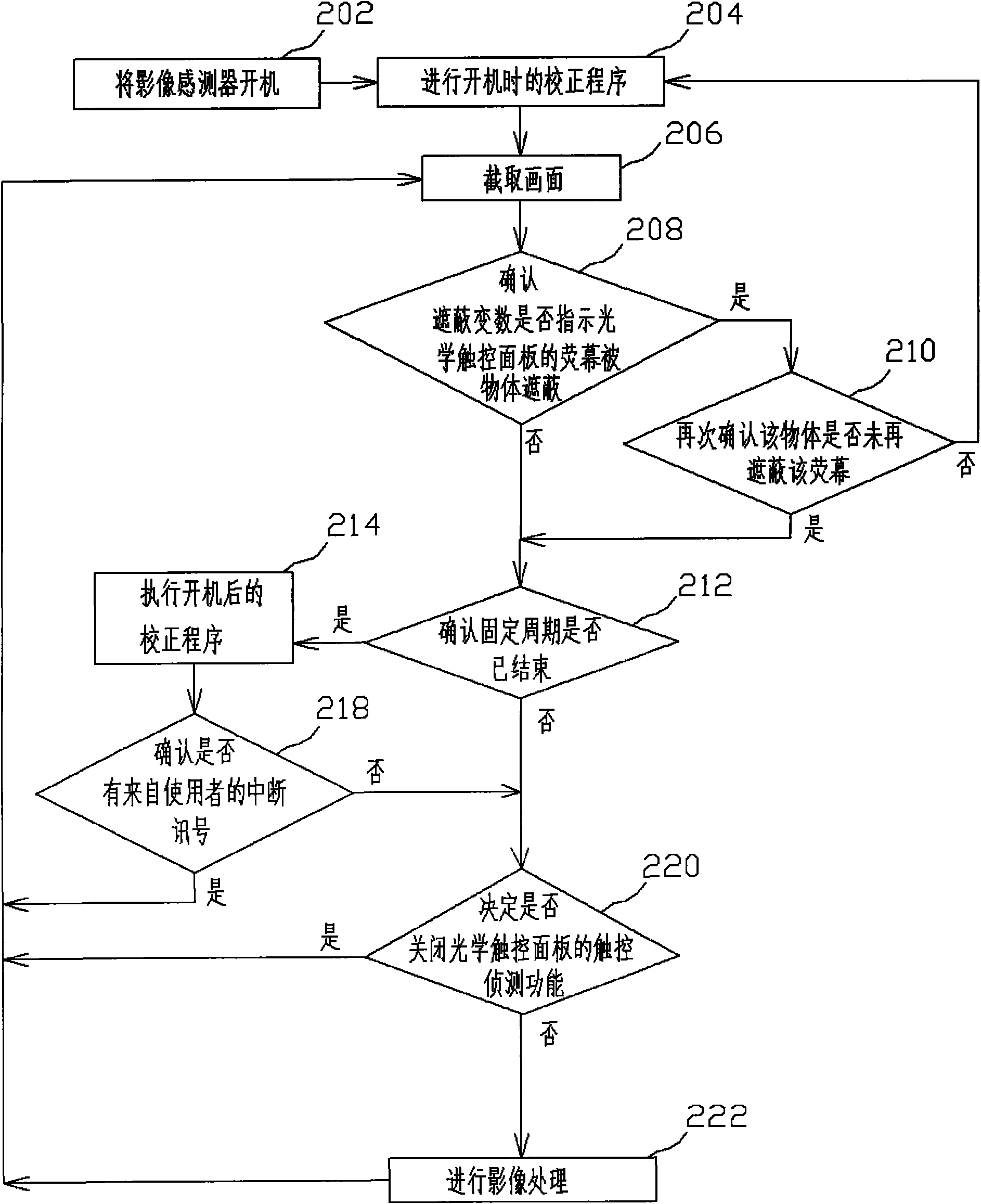

[0025] see figure 2 , which is a flowchart of a method for calibrating an image sensor disclosed in the present invention. Such as figure 2 As shown, the method for calibrating an image sensor disclosed in the present invention includes the following steps:

[0026] Step 202: Turn on the image sensor;

[0027] Step 204: Carry out the calibration procedure when starting up;

[0028] Step 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com