Single-phase multi-pole switched reluctance motor

A multi-pole switching, reluctance motor technology, applied in electric components, electrical components, electromechanical devices and other directions, can solve the problems of single-phase switched reluctance motor can not operate normally, can not effectively eliminate residual magnetism, etc., to eliminate residual magnetism , the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

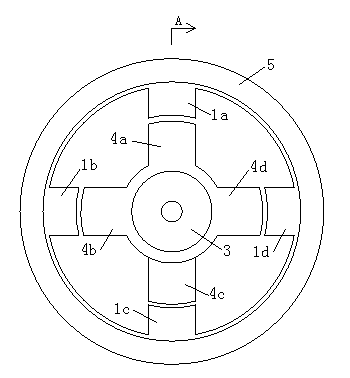

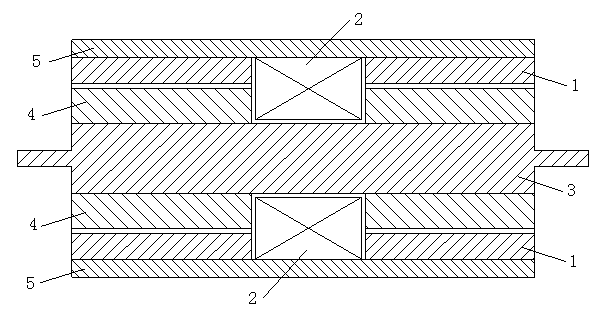

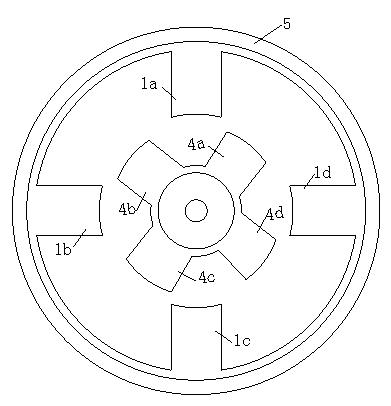

[0011] A single-phase multi-pole switched reluctance motor includes a rotor and a stator, the stator includes a stator magnetic pole 1 and an excitation coil 2, the rotor includes a rotor core 3 and a rotor magnetic pole 4, and the rotor magnetic poles are 4 sets Set on the rotor core 3, the stator magnetic pole 1 is located outside the rotor magnetic pole 4, the stator magnetic pole 1 and the excitation coil 2 are fixed in the motor housing 5, the signal input terminal of the motor controller 6 is connected to the position sensor, and the motor controls The signal output terminal of the device 6 is connected to the excitation coil 2 through the oscillator 7, such as figure 1 Shown. The excitation coil 2 is located between the motor housing 5 and the rotor core 3. The motor controller 6 is connected to the oscillator 7 through an electronic switch 8, the oscillator 7 is connected to the excitation coil 2, and the oscillator 7 is an LC series attenuated oscillator. In the LC se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com