Low-temperature emulsification process of animal oil emulsion inactivated vaccines

A technology of inactivated vaccine and process method, applied in the field of vaccine preparation, can solve the problem of easy destruction of vaccine active antigen, and achieve the effects of ideal immune efficacy, stable product quality, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

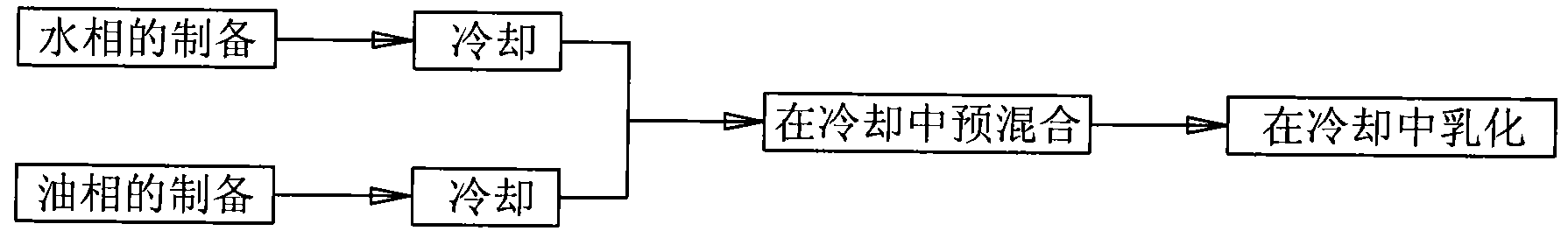

[0013] Such as figure 1 Shown, be the avian influenza (H9 hypotype F strain) inactivated vaccine emulsification process method, comprise the steps: 1), carry out the preparation of water phase in water phase tank and carry out the preparation of oil phase in oil phase tank, its The preparation method is the same as the preparation method of the prior art. After the preparation is completed, the water phase and the oil phase are cooled to 5-8°C; 2), the emulsification tank is pre-cooled, so that the temperature inside the tank is 5-8°C; 3) 1. Put the cooled water phase and oil phase together into the emulsification tank for pre-mixing, and keep the temperature in the emulsification tank at 5-8°C; 4) Perform high-speed stirring and emulsification in the emulsification tank to make the water droplets further broken and uniform Dispersed in the oil phase, during the emulsification process, keep the temperature in the emulsification tank at 5-8°C, and use cold water at a temperatur...

Embodiment 2

[0023] Also used as figure 1 The low-temperature emulsification process shown in the production of chicken Newcastle disease, avian influenza (H9 subtype F strain) dual inactivated vaccine comprises the following steps: 1), the preparation of the water phase is carried out in the water phase tank and the preparation of the water phase is carried out in the oil phase tank. The preparation of the oil phase, its preparation method is the same as the preparation method of the prior art. After the preparation is completed, the water phase and the oil phase are cooled to 5-8 ° C; 2), the emulsification tank is pre-cooled, so that the temperature in the tank is 5 -8°C; 3), add the cooled water phase and oil phase together into the emulsification tank for pre-mixing, keep the temperature in the emulsification tank at 5-8°C; 4), carry out high-speed stirring and emulsification in the emulsification tank, The water droplets are further broken and evenly dispersed in the oil phase. Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com