System for detecting activity of adsorbent

An activity detection and adsorbent technology, applied in the field of activity detection systems, can solve the problems of lack of important forms of mercury in coal-fired flue gas, inability to detect the content of total mercury and elemental mercury in an adsorption reactor at the same time, and achieve convenient and practical pipeline design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

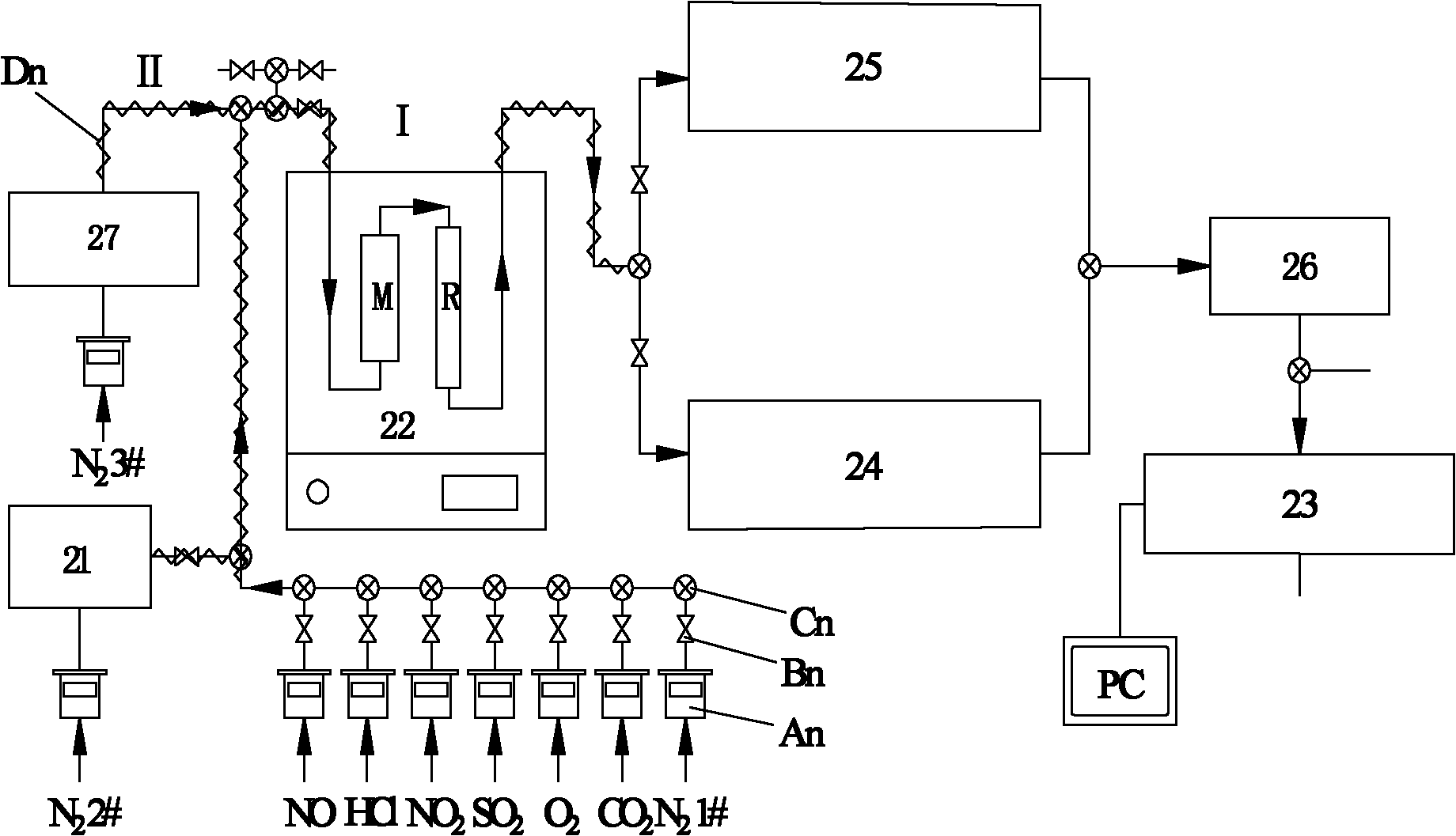

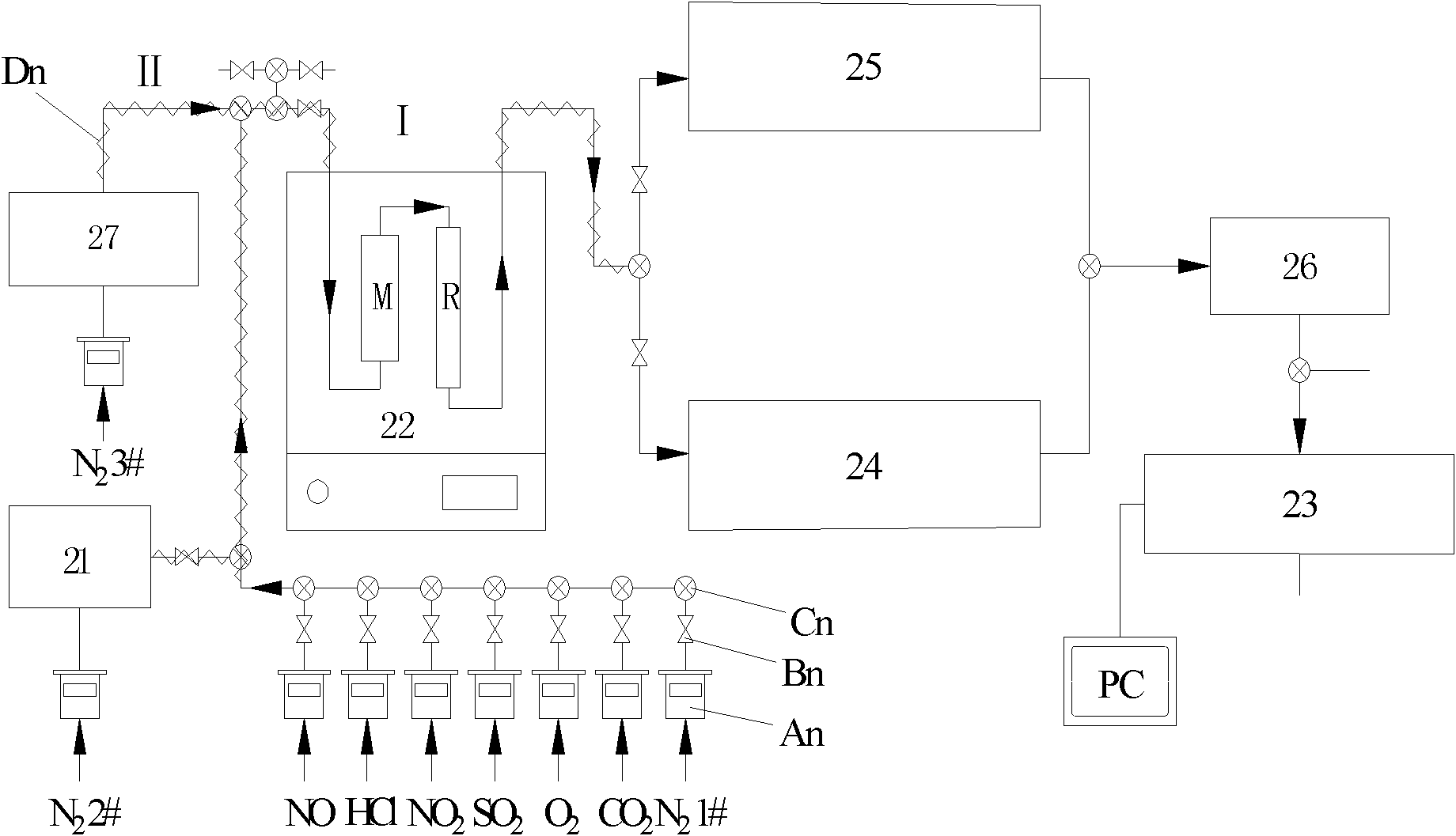

[0019] The invention is provided with a simulated coal combustion flue gas gas phase mercury generating unit, a reaction unit and a detection unit.

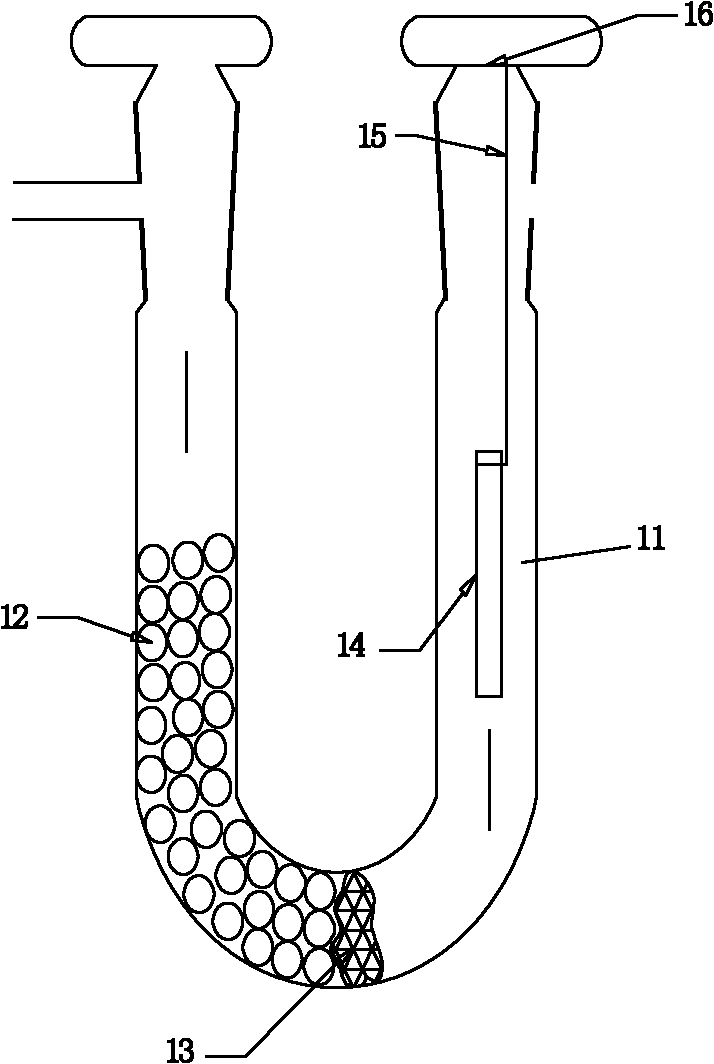

[0020] The gas-phase mercury generating unit of the simulated coal-fired flue gas is equipped with N 2 Cylinder, CO 2 Cylinders, SO 2 Cylinder, O 2 Cylinder, NO 2 Gas cylinders, HCl gas cylinders, NO gas cylinders, mass flow controllers, Hg 0 Permeation tube, Hg 2+ Permeation tube and constant temperature water bath. In the constant temperature water bath, there is a gas washing bottle for generating moisture and a gas-phase mercury (Hg 0 or HgCl 2 ) of mercury permeation tube, and a constant flow of stripping carrier gas N is passed through the gas washing bottle 2 , the mercury permeation tube is set in the quartz U-shaped tube, the U-shaped tube is equipped with a frosted hollow quartz glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com