Regular octagonal template-based board camera intrinsic parameter calibration method

A camera internal parameter and camera calibration technology, applied in the field of computer vision, can solve the problems of sensitive initial value selection, unsuitable for placing accurate calibration reference objects, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and examples.

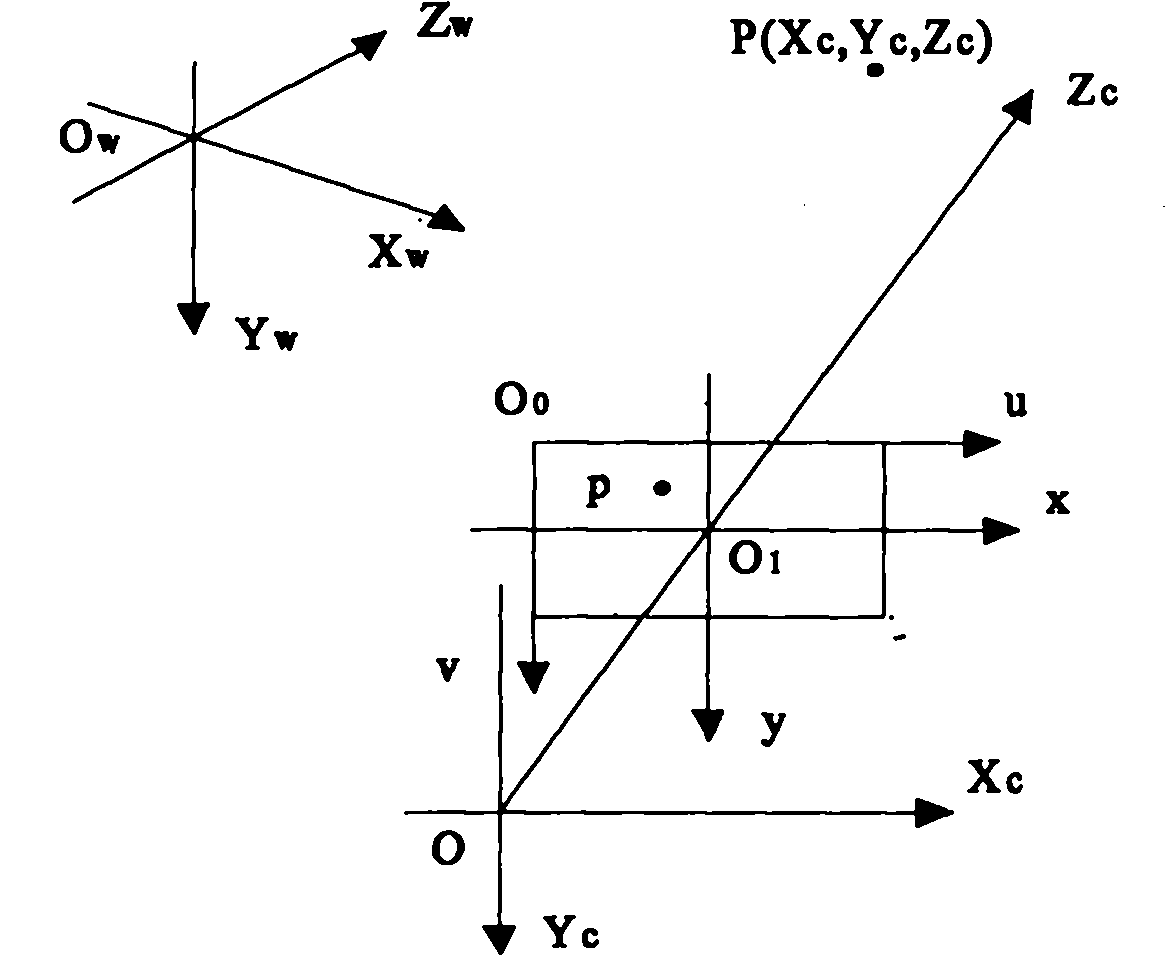

[0051] figure 1 It is a schematic diagram of the computer image coordinate system (u, v), the imaging plane coordinate system (x, y), the camera coordinate system (Xc, Yc, Zc) and the world coordinate system (Xw, Yw, Zw). Computer image coordinate system (u, v): Each digital image is stored in the form of an array in the computer, and the value of each element (pixel) of the array is the brightness of the image point. The origin is located at the upper left corner of the image plane, and the coordinates (u, v) of each pixel represent the number of columns and rows of the pixel in the array, respectively. Imaging plane coordinate system: the origin is located at the intersection of the camera optical axis and the image plane, and the x and y axes are parallel to the u and v axes respectively, expressed in physical units (such as millimeters). Camera coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com