A touch screen glass conveying and discharging device

A technology of discharging device and touch screen, applied in conveyor objects, transportation and packaging, furnace and other directions, can solve the problems of inconvenient removal of glass, affecting production efficiency, glass falling, etc., to facilitate removal of glass, reduce movement frequency, prevent glass falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

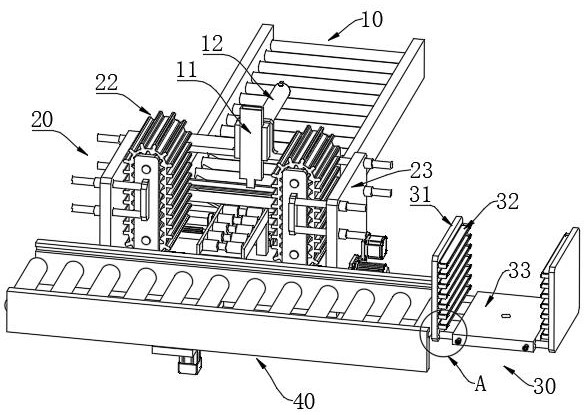

[0039] Such as Figure 1 to Figure 7 As shown, a touch screen glass conveying and discharging device includes: a conveying line 10 , a stacking mechanism 20 and a discharging frame 30 .

[0040] Specifically, the conveying line 10 is used for conveying glass, and a push plate 11 is arranged above the outlet end thereof, and the push plate 11 is moved vertically so as to change the height position of the push plate 11 . The push plate 11 is arranged to move along the conveying direction of the conveying line 10 , and is used to simultaneously push the glass stacked in the stacking mechanism 20 into the discharge frame 30 .

[0041] Specifically, the stacking mechanism 20 is arranged at the outlet end of the conveying line 10 . The stacking mechanism 20 includes a conveying roller set 21 parallel to the conveying line 10, and all rollers of the conveying roller set 21 can actively rotate for moving glass.

[0042]Conveyor belts 22 parallel to each other are arranged on both si...

Embodiment 2

[0048] Such as figure 1 , Figure 4 As shown, a touch screen glass conveying and discharging device further includes a material frame track 40 , which is arranged at the outlet end of the stacking mechanism 20 and is used for conveying the material frame 30 . The conveying direction of the material frame track 40 and the conveying direction of the conveying line 10 are perpendicular to each other.

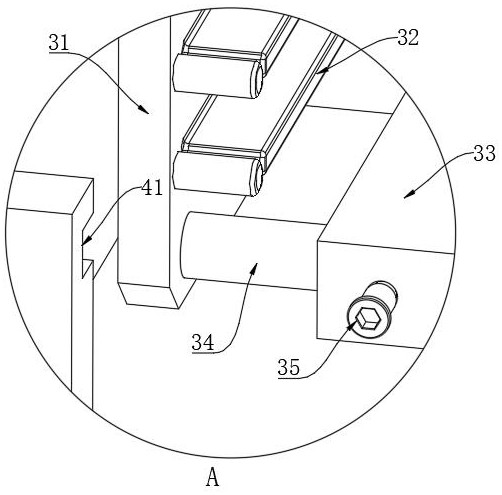

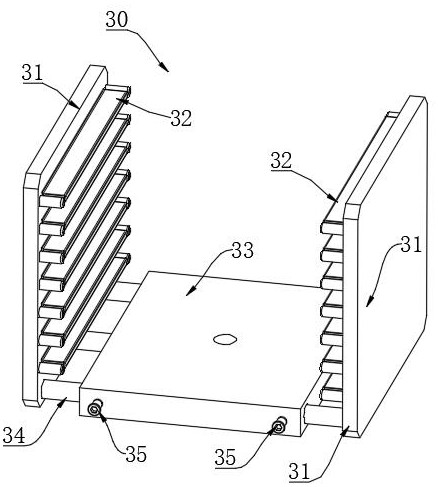

[0049] More specifically, such as figure 2 , image 3 As shown, the discharge frame 30 also includes a bottom plate 33, and the side plates 31 are pierced through the bottom plate 33 by at least two round rods 34 for adjusting the distance between the side plates 31; Locking screw rods 35 are pierced on both sides for compressing the round rod 34 . The inner wall of the skeleton on both sides of the material frame track 40 is provided with a bar-shaped groove 41 along the conveying direction. The stability when the discharge frame 30 moves.

[0050] preferred, such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com