Fast side discharge method of walking hearth furnace

A side-discharging, rapid technology, applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems that the furnace cannot meet the process requirements, affect the thermal processing performance of the billet, and cool down, so as to improve labor productivity and improve heating Quality, the effect of reducing the frequency of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

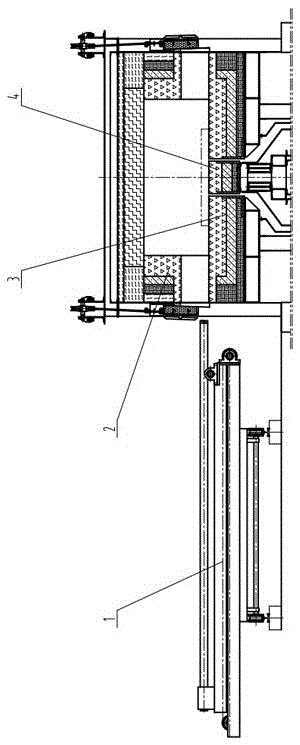

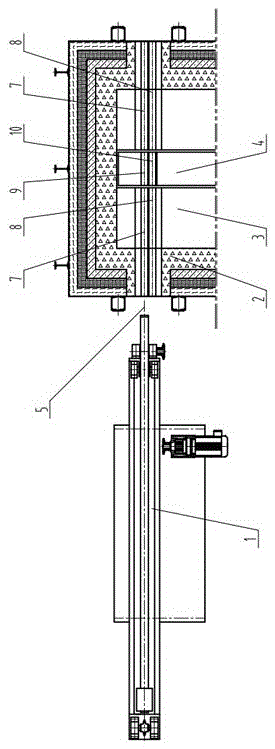

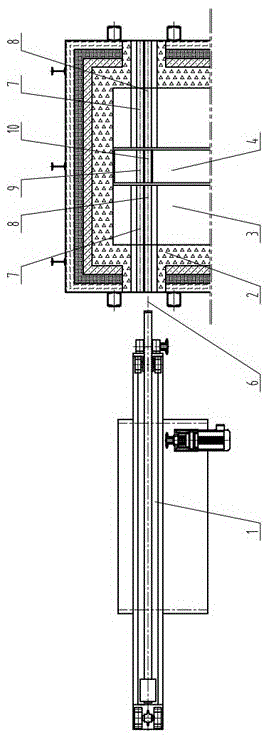

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] In summary, the present invention discloses a method for quick side discharge of a walking hearth furnace, comprising the following steps:

[0025] Step 1: The moving bed 4 rises from the initial position, that is, the rear low position. When the upper surface of the moving bed 4 is at the same height as the upper surface of the fixed bed 3, the moving bed 4 lifts the billet placed on the fixed bed and continues to rise to the highest position ;

[0026] Step 2: After the moving bed 4 reaches the highest point, it stops moving upwards, and under the push of the driving device, it advances horizontally toward the discharge end for a distance of more than one material distance. After the moving bed 4 reaches the position, the moving bed 4 stops moving;

[0027] Step 3: The movable bed 4 moves vertically downwards, and stops when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com