Beverage preparation device with in-line scale removal system and descaling method using such system

A technology for beverage preparation and equipment, which is applied in the field of automatically removing limestone scale in beverage preparation equipment, and can solve the problems of difficulty in controlling the scale removal agent and the effective amount of flushing liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

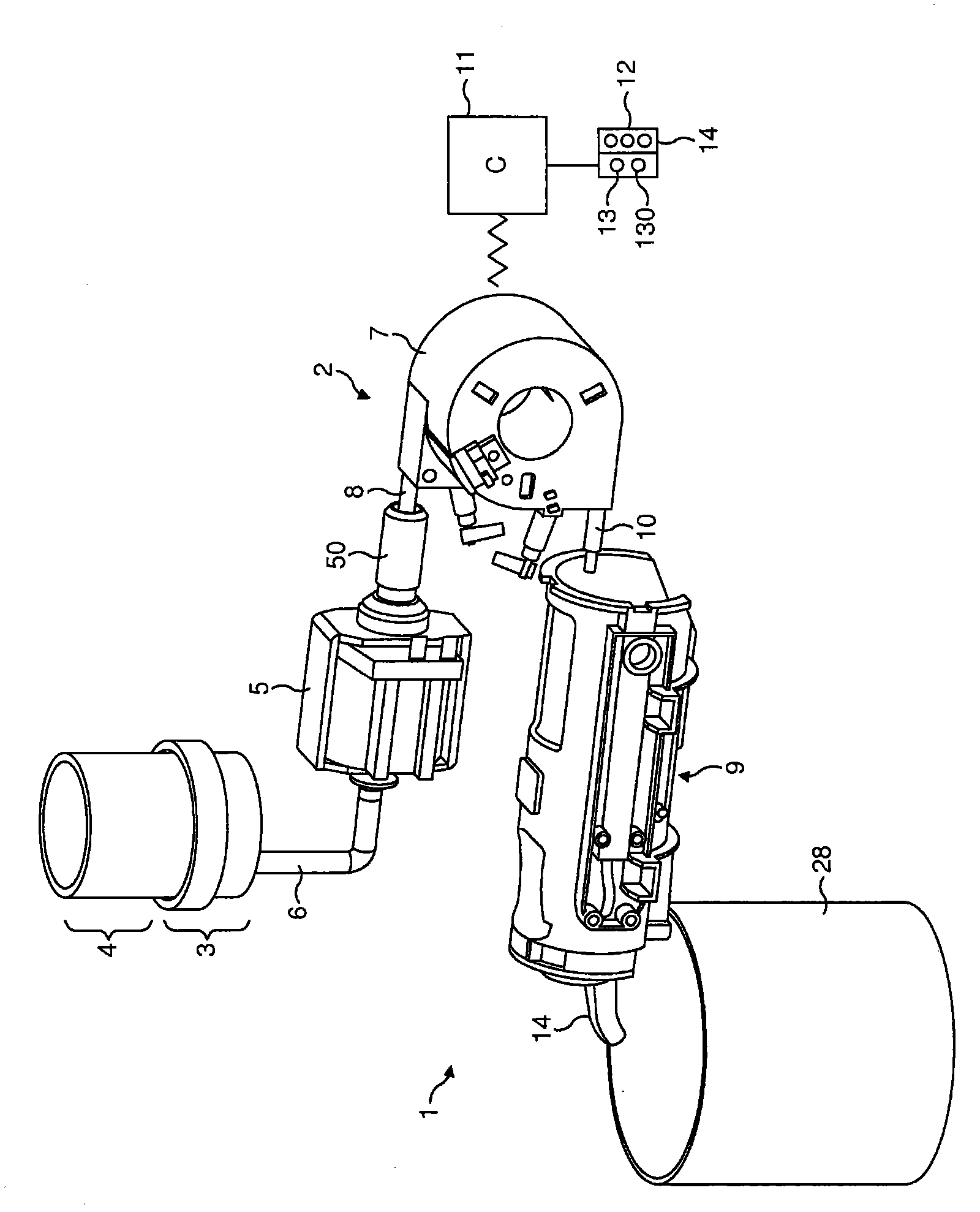

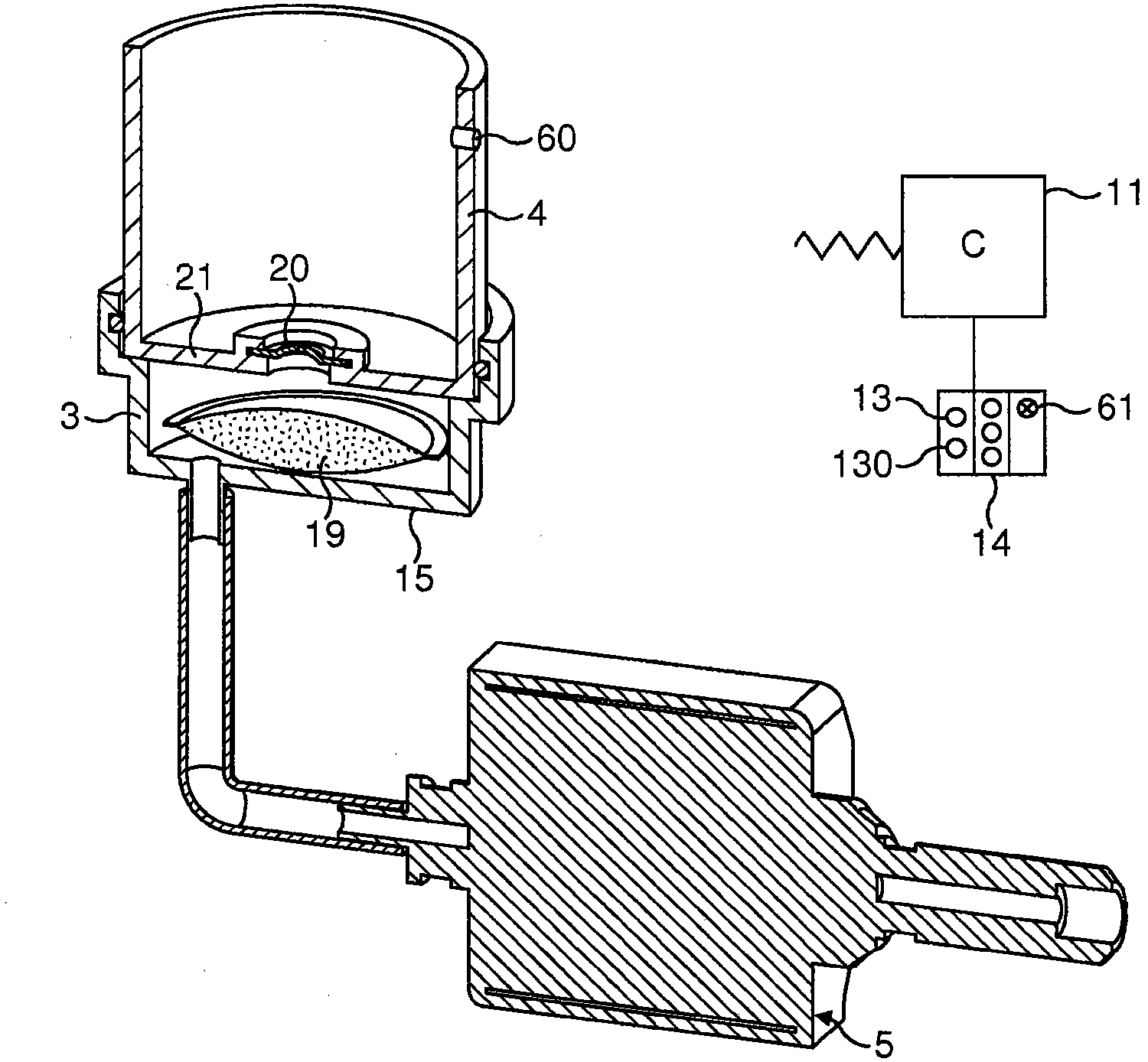

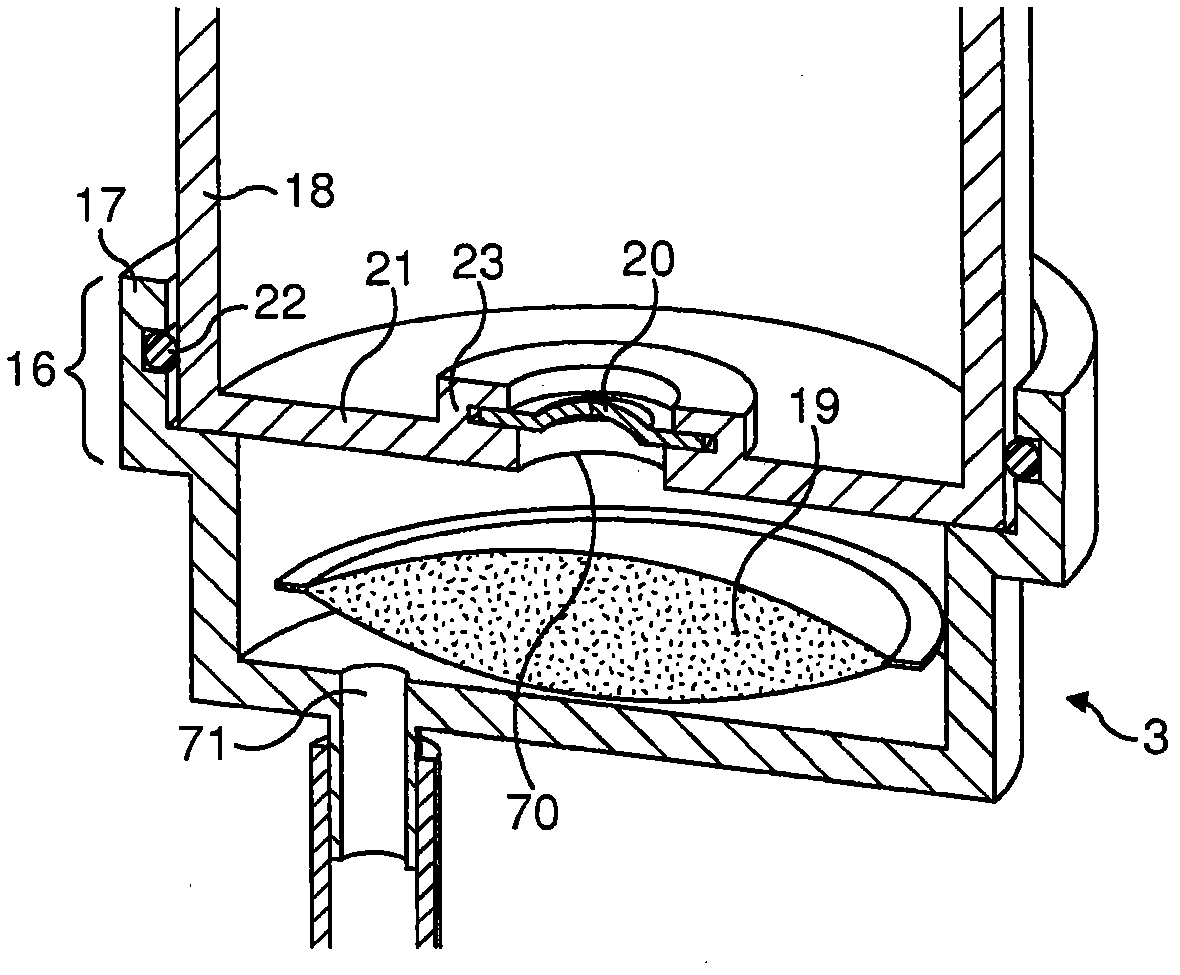

[0049] figure 1 Shown is a beverage preparation device such as a coffee machine 1 comprising the main components forming a fluid circuit 2 and a built-in descaling system 3 according to the principles of the invention. The machine generally includes a water supply, which may be a water reservoir 4 . The water reservoir is in fluid communication with the water delivery means, ie the pressure pump 5 , via the first part 6 of the hose. The pump itself is in downstream fluid communication with an inline heating element such as a thermoblock 7 . The pump 5 and the heat block 7 may be joined together by a second portion 8 of hose. A flow meter 50 may be provided in the fluid circuit to detect the flow of liquid circulating in the circuit. Downstream of the thermoblock 7 there is provided a beverage production module 9 which receives heated water from the thermoblock via a third portion 10 of the hose. A control unit 11 is provided to control the switching of the pump and the the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com