Method for intelligently inspection substation equipment by using robot

A technology of intelligent inspection and substation, applied in the direction of instruments, non-electric variable control, position/direction control, etc., can solve the problems of manual inspection danger, large manpower and time consumption, difficulty in emergency command and dispatch, etc., and achieve accurate data Effective, labor cost saving, convenient and reliable inspection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

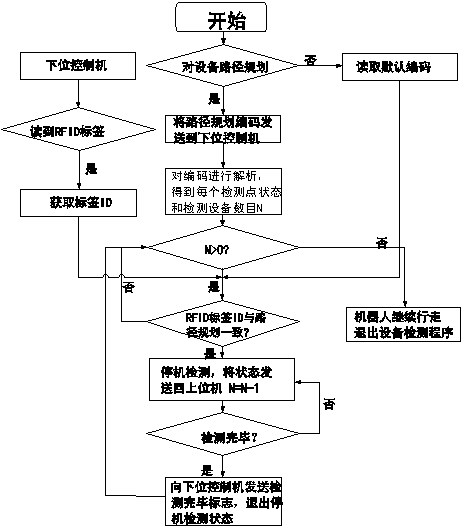

[0026] Such as figure 1 As shown, the method for intelligent inspection of substation equipment using robots of the present invention includes the following steps:

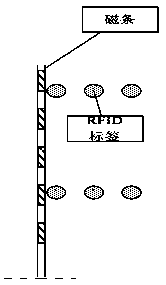

[0027] 1) Set up RFID tags at the detection points of electric equipment, and store positioning information in the RFID tags, store the information corresponding to each RFID tag in the upper control host and the lower control machine on the inspection robot, and install RFID on the inspection robot reader;

[0028] 2) After the detection is started, the following steps are also included:

[0029] 2.1) The lower control machine inquires whether it is necessary to plan the inspection path. If so, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com