Hydropress with bidirectional couple levelling function

A hydraulic press and even adjustment technology, applied in the field of hydraulic press machinery, can solve the problems of low leveling accuracy and production efficiency, long leveling response time, loss of main tonnage of the press, etc., to avoid the loss of main tonnage, reduce production costs, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

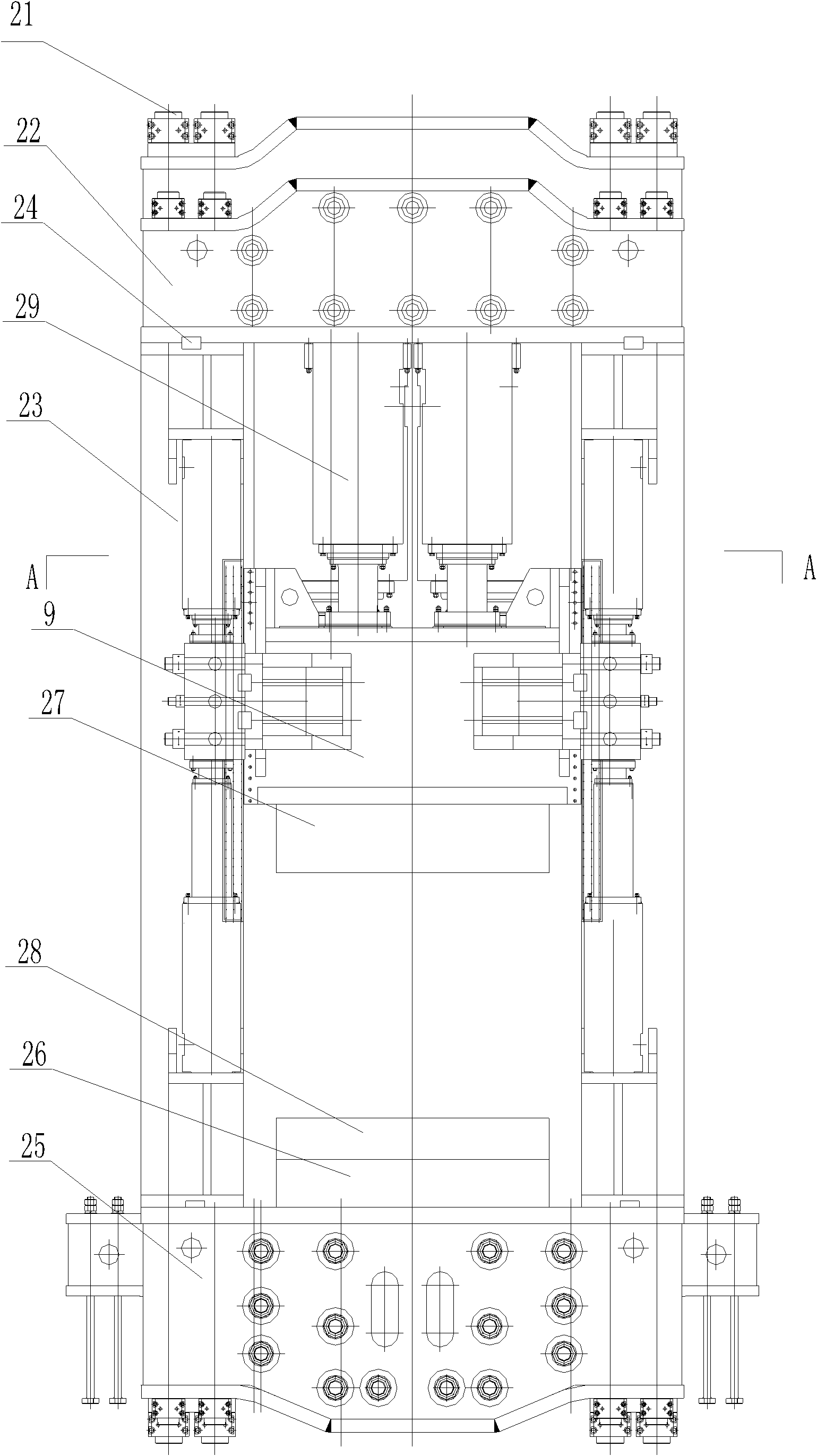

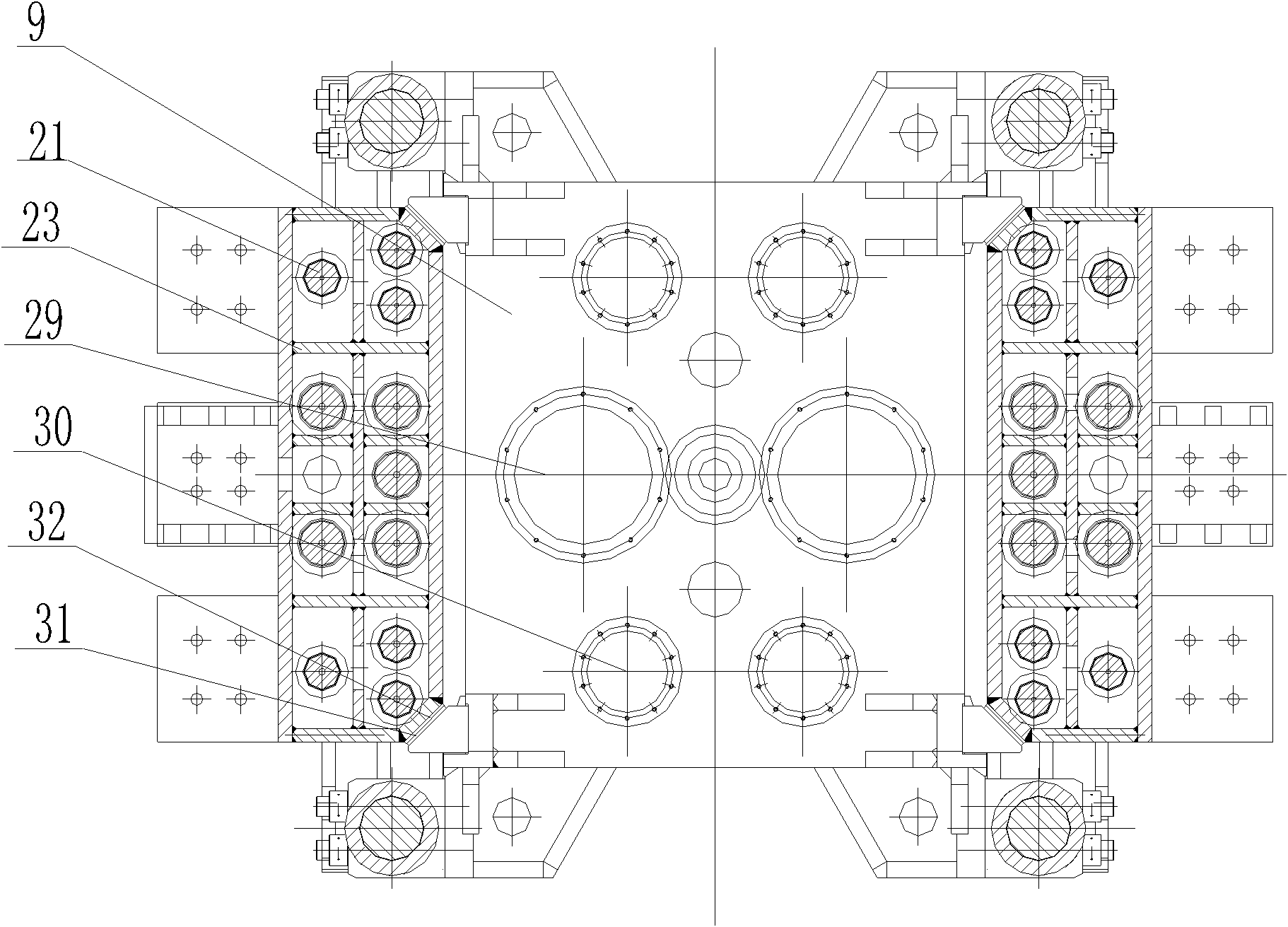

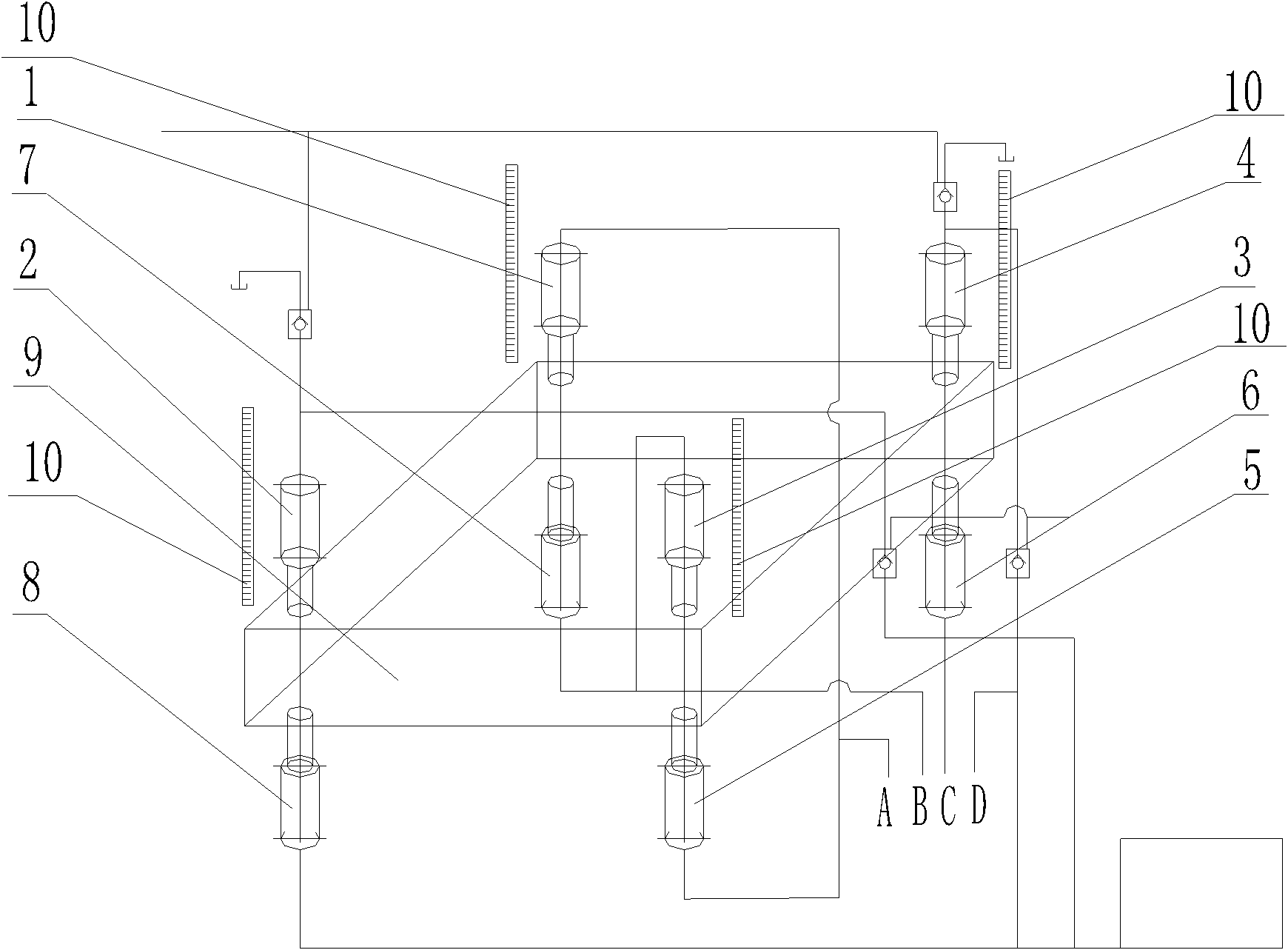

[0010] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are cited hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings: Please refer to Figure 1-Figure 4 , a hydraulic press with two-way force couple leveling function, including an upper crossbeam 22, four pillars 23 and a lower crossbeam 25, which are preloaded by pull rods 21 to form a closed frame body. The main oil cylinder 29 and the side oil cylinder 30 are fixedly installed on the upper beam, and the slide block 9 is connected with the main oil cylinder and the side oil cylinder. A guide plate 31 is fixed on the inner side of the four pillars. An upper template 27 is fixed on the end face, and a lower template 28 is installed on the lower beam through a workbench 26 . The upper and lower parts of each pillar are fixedly equipped with leveling oil cylinders, and the leveling oil cylinders on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com