High-low pressure buffer system

A buffer system, high and low pressure technology, applied in the field of buffer devices, can solve the problems of buffer cylinder design, slow movement, energy consumption and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

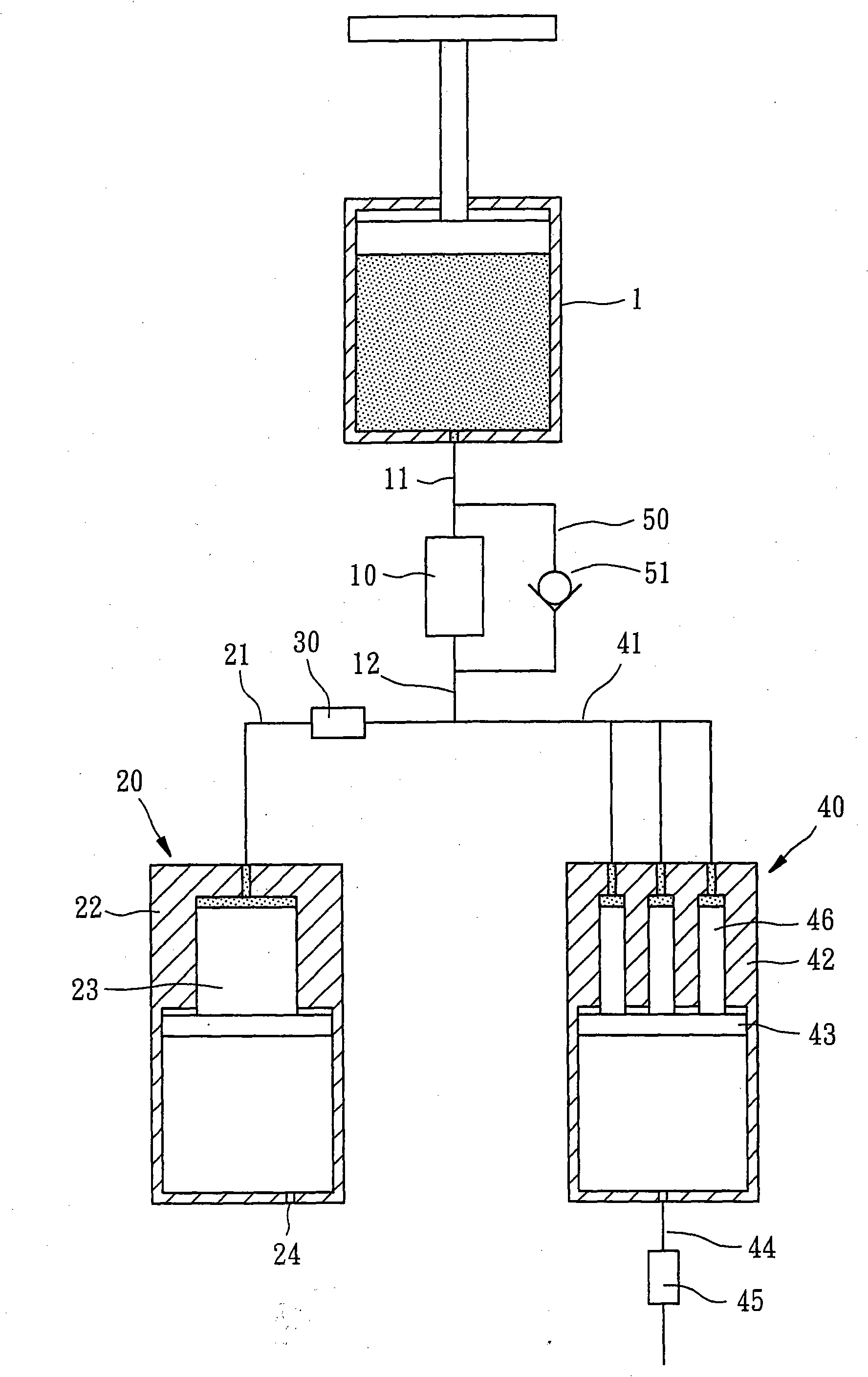

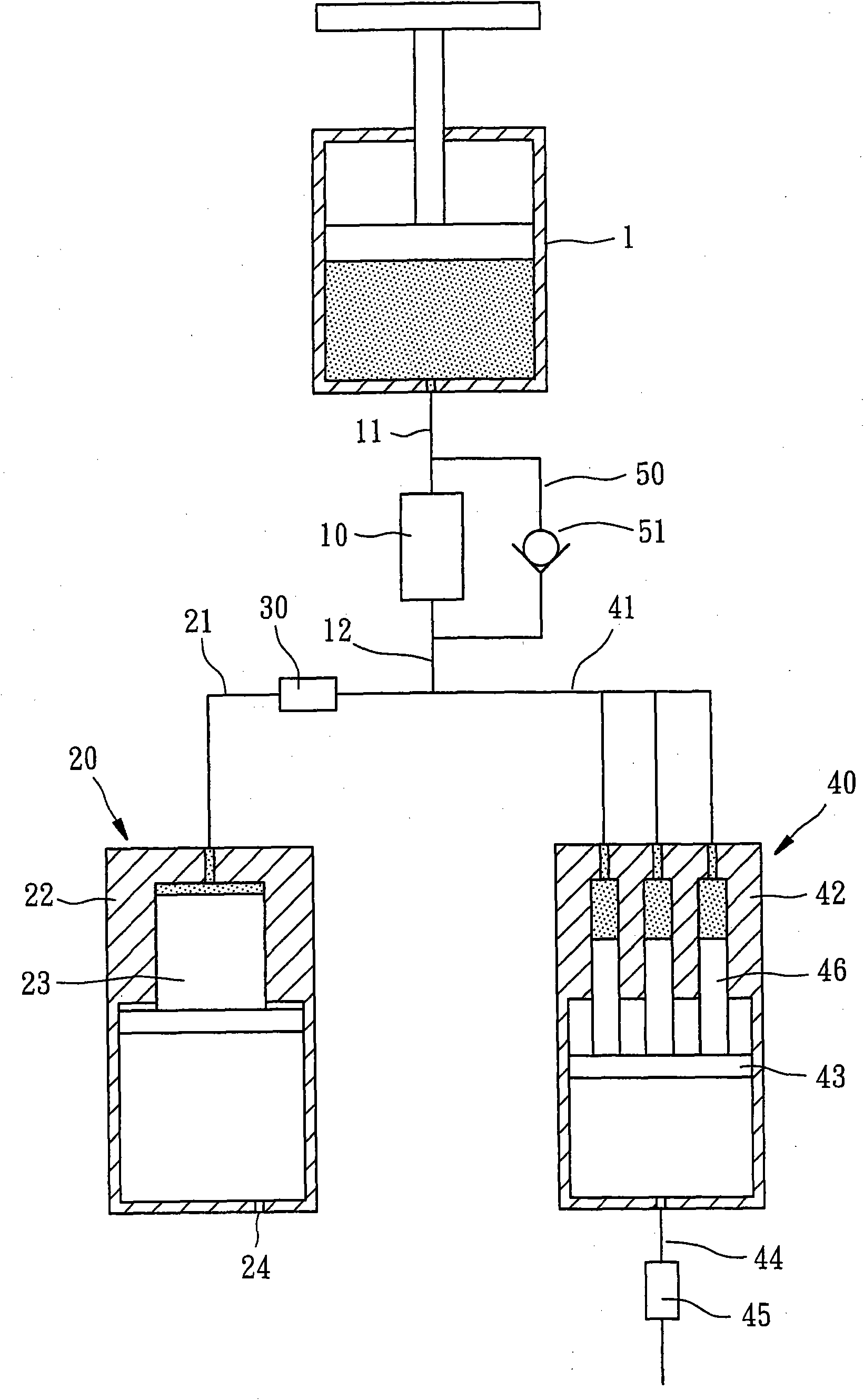

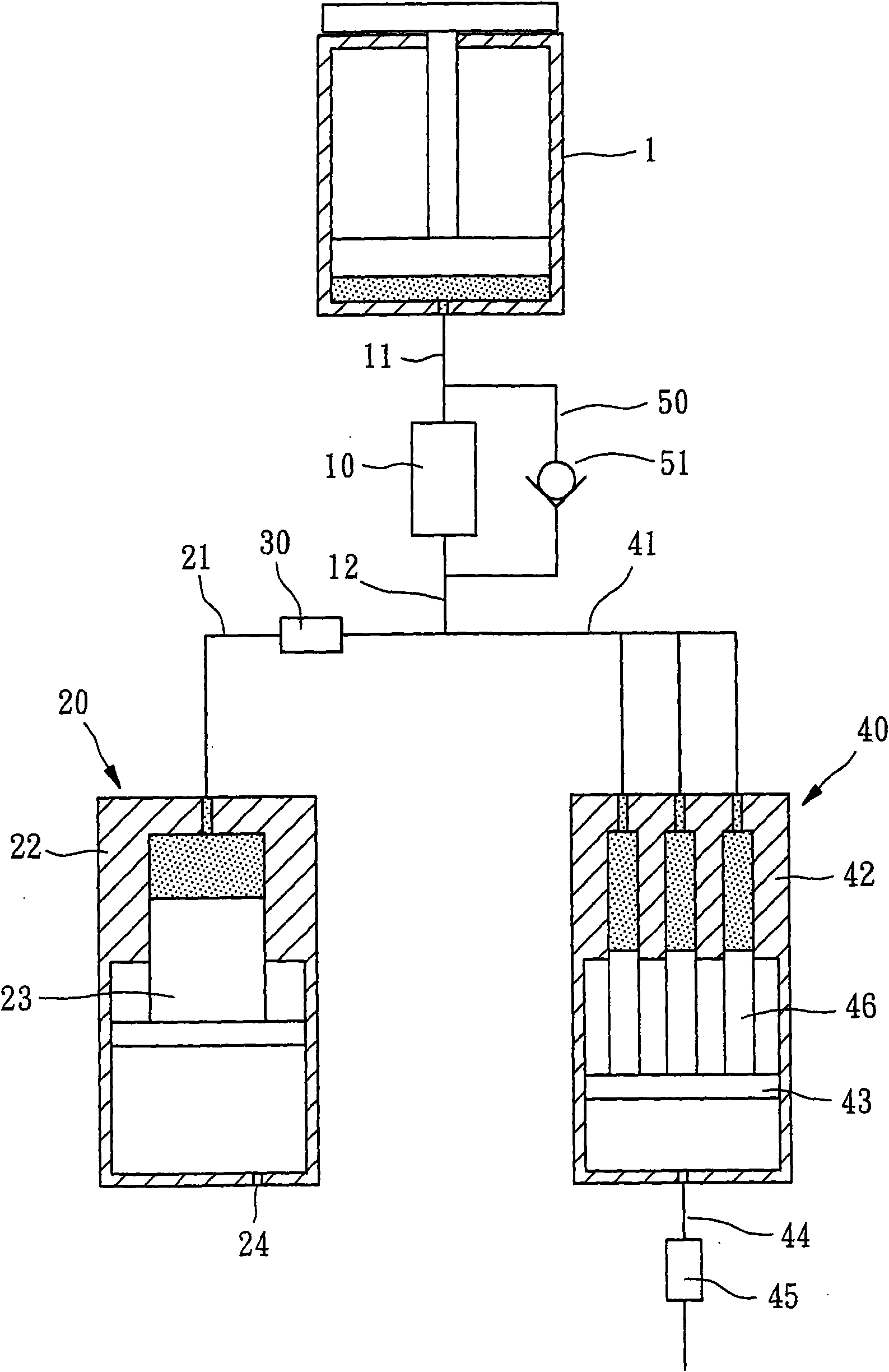

[0015] The structure, characteristics and effects of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

[0016] First, if Figure 1 ~ Figure 4 As shown, the high and low pressure buffer system of the present invention is used to connect with the buffer cylinder 1 of the general press machine. The high and low pressure buffer system of the present invention includes:

[0017] A pressure regulating valve 10, one end is connected to a front oil delivery pipe 11 and the other end is connected to a rear oil delivery pipe 12, the front oil delivery pipe 11 of the pressure regulating valve 10 communicates with the buffer cylinder 1 of the punch press, and the pressure regulating valve 10 can be adjusted to set and control the pressure value of the buffer cylinder 1 .

[0018] A low-pressure pneumatic cylinder 20 is connected to the rear oil delivery pipe 12 of the pressure regulating valve 10 with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com