Cutting and fixing device and cutting method of sheet part

A technology of fixing device and cutting method, applied in shearing devices, accessories of shearing machines, metal processing equipment, etc., can solve the problems of scrap parts, unstable pneumatic pressure, tool jumping, etc., to reduce the probability of scrapping and ensure safety. Improve and avoid the effect of knife jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

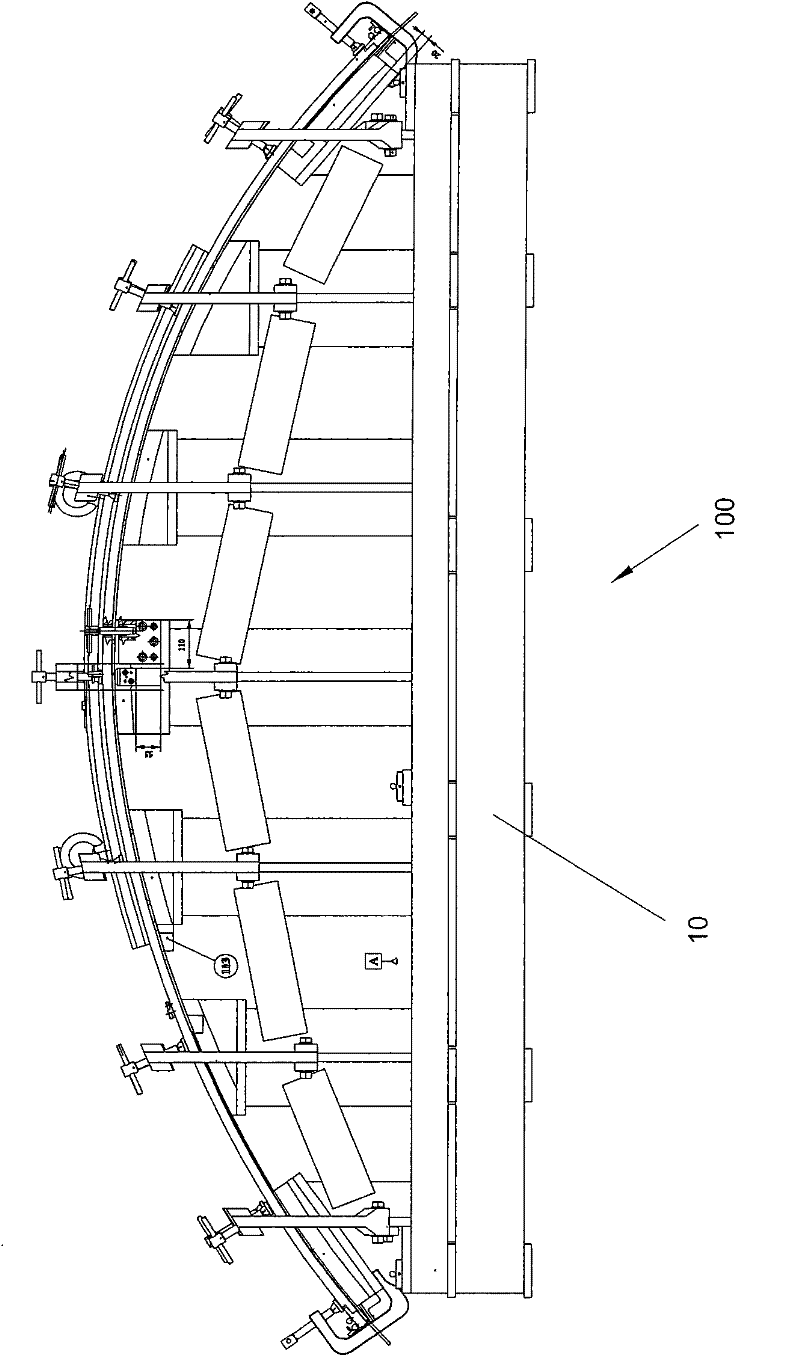

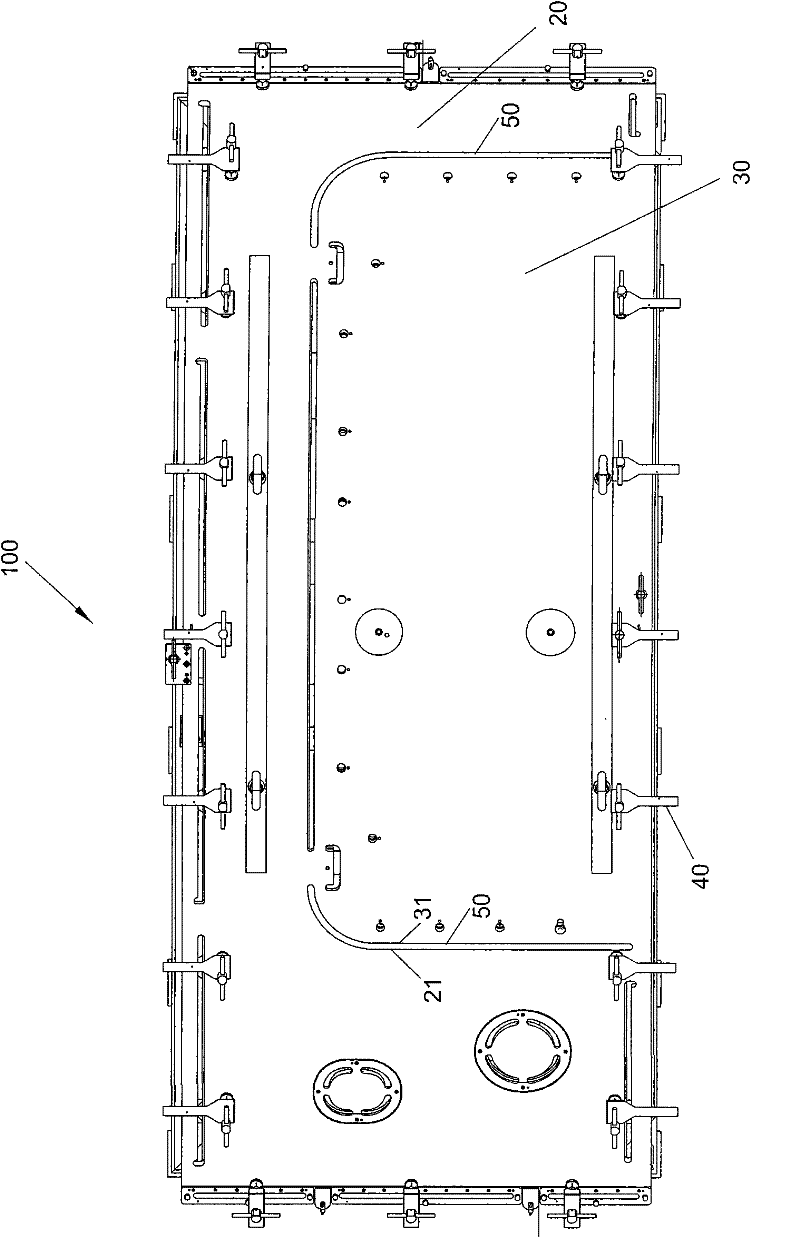

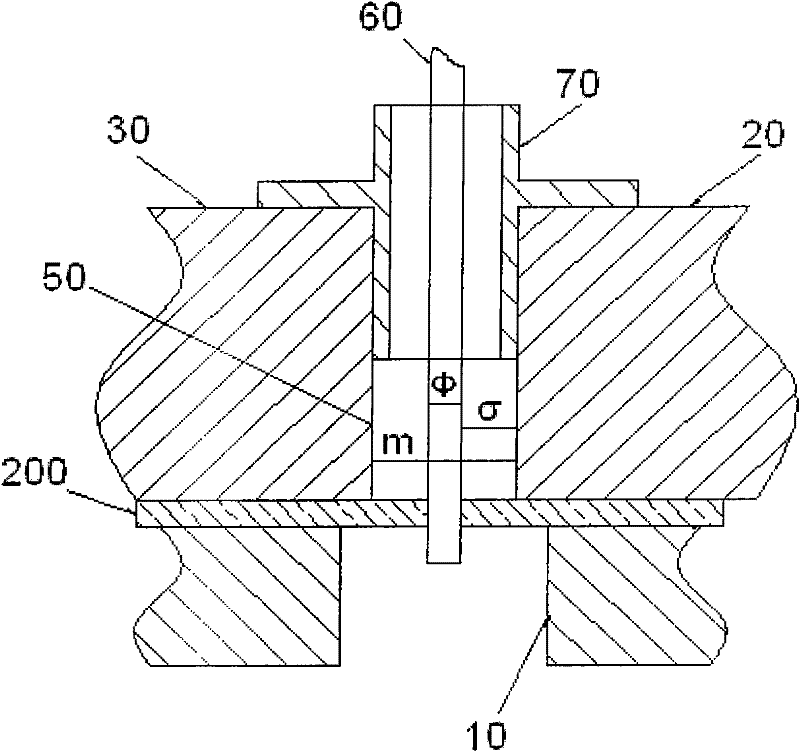

[0032] figure 1 A side view of a cutting fixture 100 according to a preferred embodiment of the present invention is shown, figure 2 A top view of the cutting fixture 100 is shown. Wherein, the cutting fixture 100 includes a supporting base 10, which is used to support and fix the parts 200 to be cut (see image 3 ), clamps or any other fixing device can be used. The cutting and fixing device 100 also includes a first resting part 20 and a second resting part 30 for pressing against the part to be cut. Wherein, the inner side 21 of the first backing member 20 has a shape consistent with the desired outer contour of the part, and the outer side 31 of the second backing member 30 has a shape complementary to the desired outer contour of the part. The first backing part 20 and the second backing part 30 are rotatably mounted on the supporting base 10 and can be fixed on the supporting base 10 by using a pressing plate 40 or other devices. When the first rest member 20 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com