Resin molded component for vehicle and manufacturing method thereof

一种树脂成型、成型部件的技术,应用在车辆部件、家用元件、应用等方向,能够解决折叠位置偏离等问题,达到容易折叠、减小抗弯刚度、防止毛边的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Exemplary embodiments of the invention will refer to Figure 1-Figure 12 Described below.

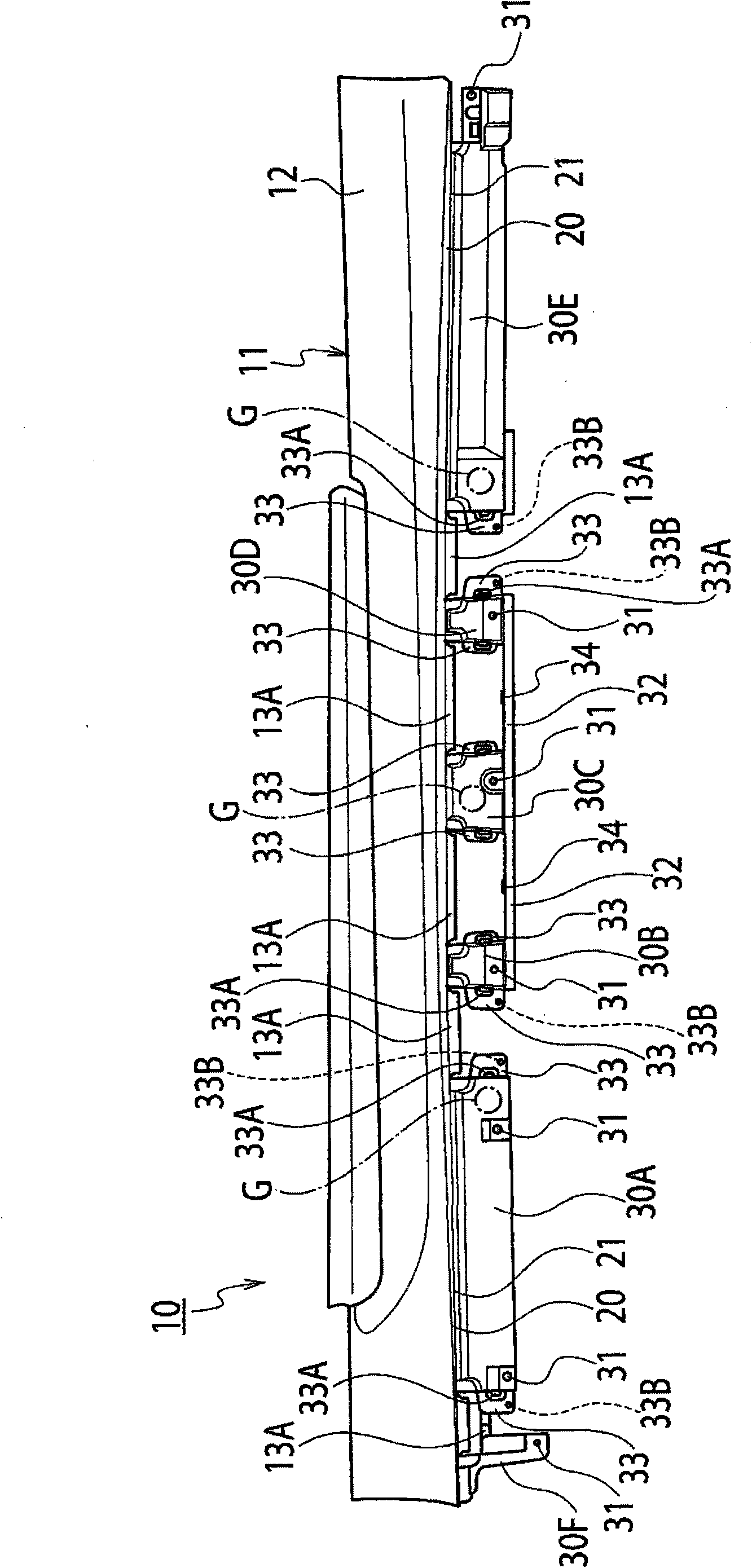

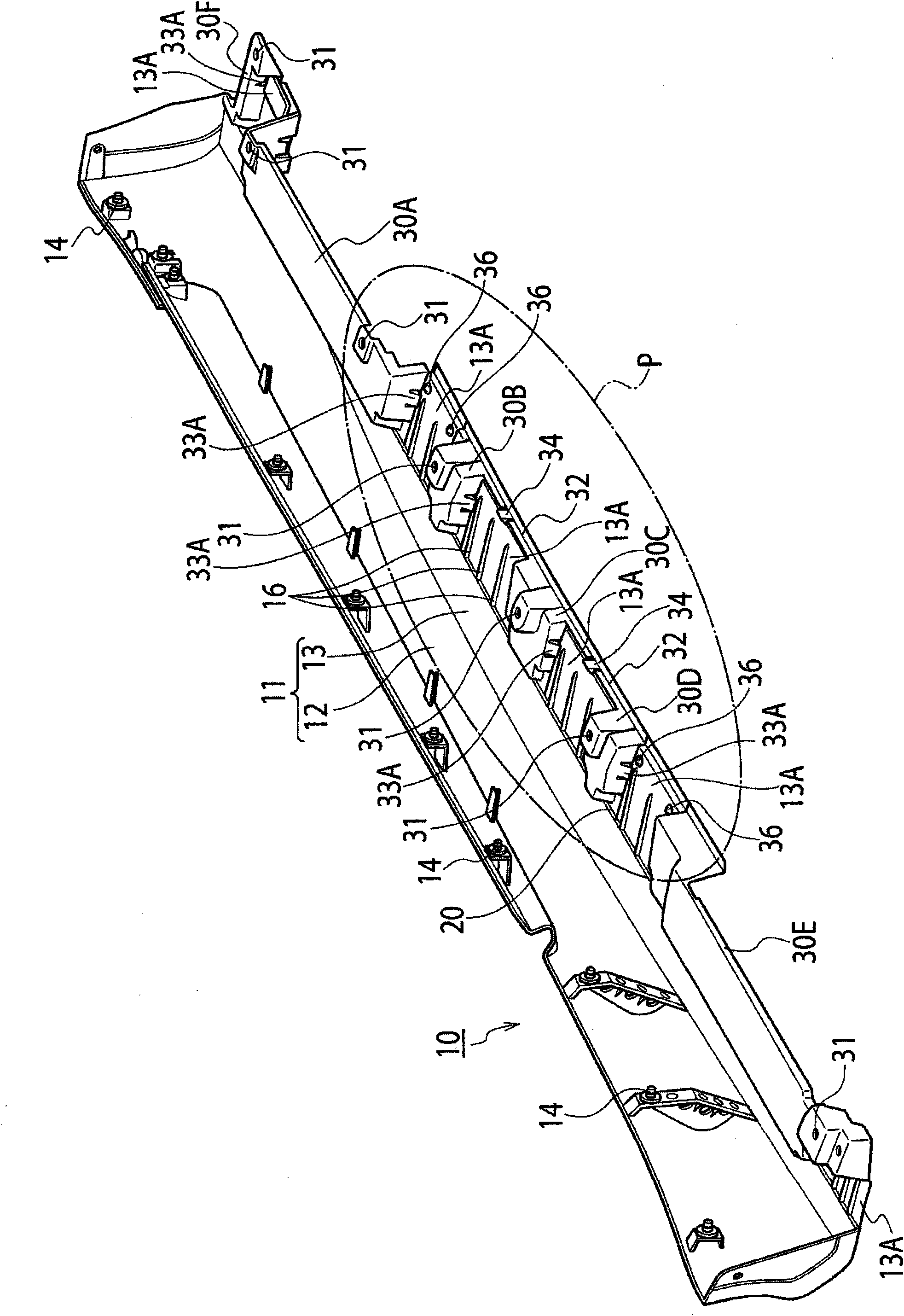

[0036] figure 1 is a schematic perspective view of the vehicle 1 . figure 2 is a side view of the rocker cover 10 with the attachments 30A- 30F in the injection molding position. image 3 is a perspective view of the rocker cover 10 viewed from the inner surface side of the rocker cover 10 with the attachment portions 30A- 30F in the vehicle installation position. Figure 4 is a perspective view of the rocker cover 10 viewed from the inner surface side of the rocker cover 10 with the attachment portions 30A- 30F in injection molding positions. Figure 5 is a perspective view of the rocker cover 10 viewed from the outer surface side of the rocker cover 10 with the attachment portions 30A- 30F in the vehicle installation position. Figure 6 is a perspective view of the rocker cover 10 viewed from the outer surface side of the rocker cover 10 , with the attachment portions 30A-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com