Method for detecting cleaness of furnace gas in continuous annealing furnace

A continuous annealing furnace, furnace gas technology, applied in the direction of furnace, furnace type, heat treatment furnace, etc., to achieve the effect of reliable judgment basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

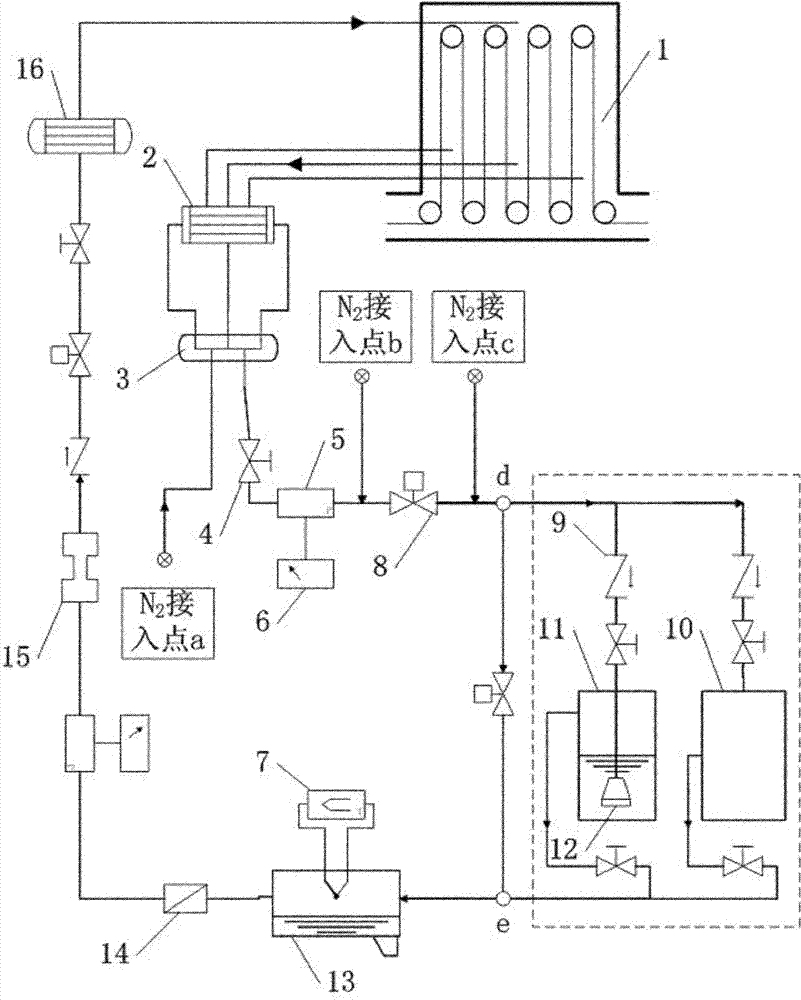

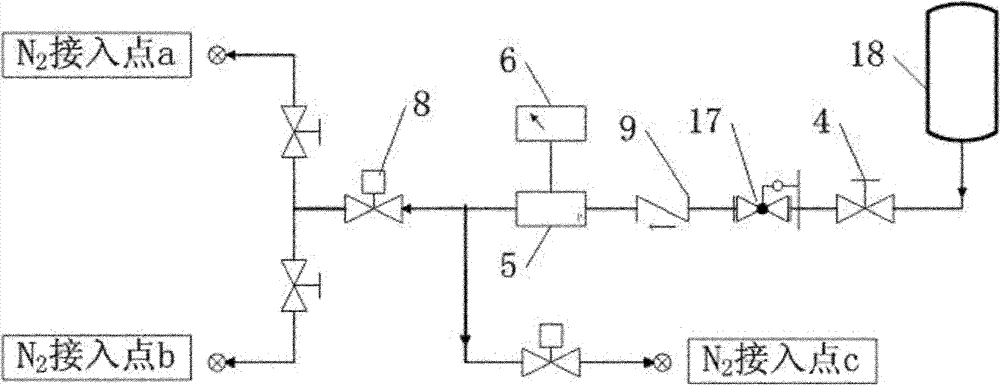

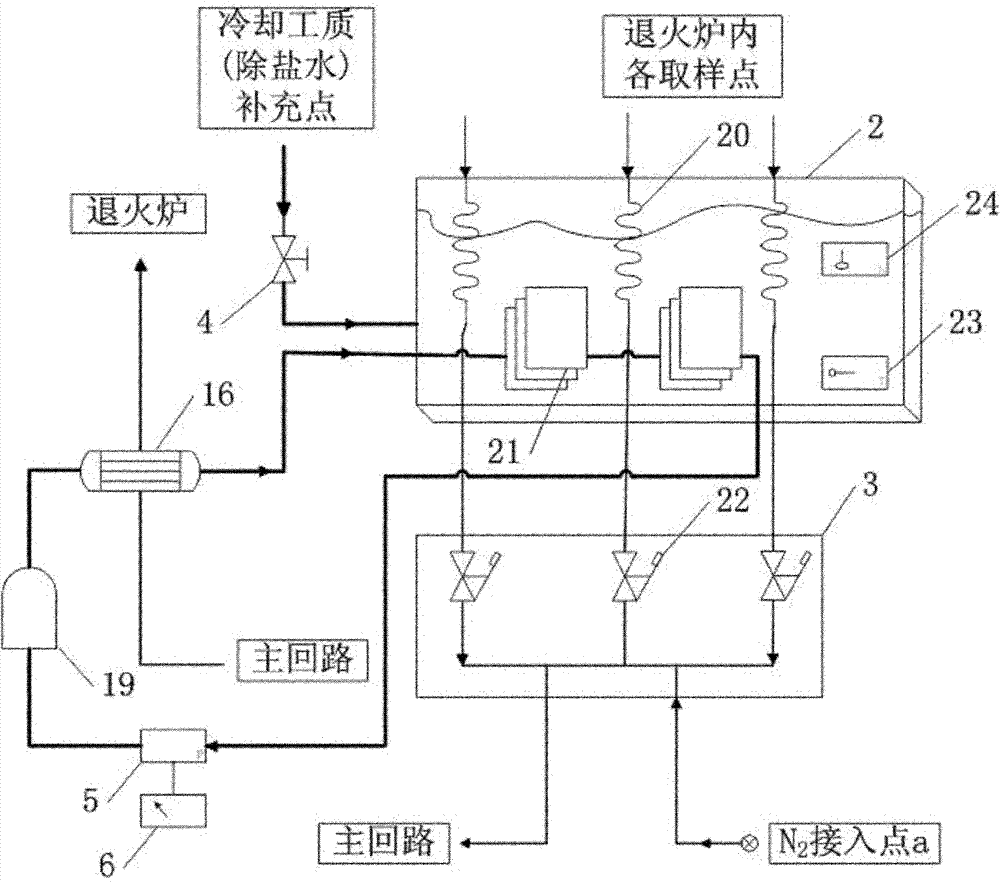

[0021] The method for detecting the cleanliness of the gas in the continuous annealing furnace provided by the present invention is specifically: use a sampling metering pump to extract the gas in the furnace chamber of the annealing furnace, and make the furnace gas pass through the collector according to the set flow rate, and the various pollutants in the furnace gas is blocked in the collector. The sampling metering pump will automatically measure the volume of the collected furnace gas, and convert the volume unit into standard cubic meters according to the temperature and pressure measured by the instrument in front of the sampling metering pump. According to the weight difference of the filter element of the total pollutant collector before and after sampling, the total weight of suspended particulate matter in the sampling furnace area can be obtained, so as to obtain the concentration of particulate matter in the furnace gas. By detecting the total amount of furnace g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com