Detection system for detecting oil content in gas in continuous annealing furnace on line

A technology of continuous annealing furnace and gas in the furnace, which is applied in the fields of medium and high-grade automobiles, heat treatment of cold-rolled metal strips, and home appliance panel production, and can solve the problems of increased operational difficulty and misjudgment, no detection method and device proposed, and equipment damage in the furnace and other issues to achieve the effect of eliminating the probability of downgrading or unqualified, increasing the probability of misjudgment, and increasing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method provided by the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

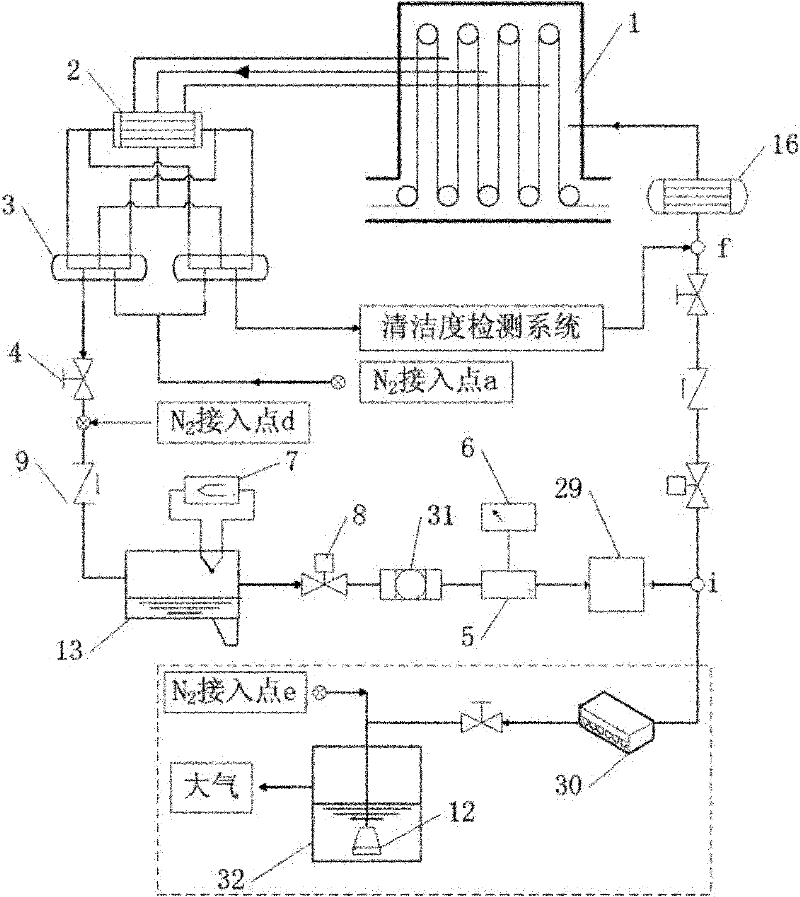

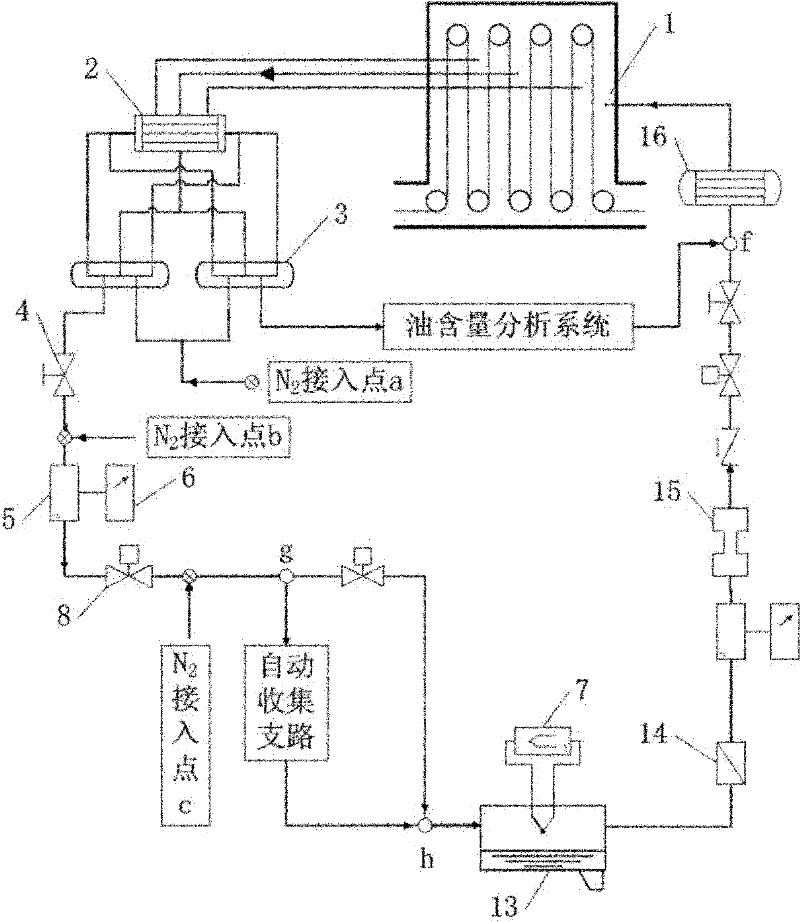

[0027]The detection system (hereinafter referred to as "analysis system") for on-line detection of the oil content in the gas in the continuous annealing furnace provided by the present invention is mainly composed of two parts: the analysis main circuit and the analysis branch circuit.

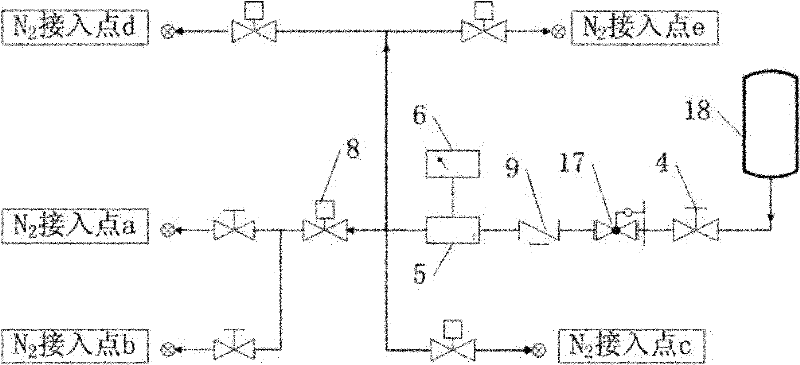

[0028] The analysis main loop is as figure 1 The part outside the dotted line box shows: according to the air flow direction, the sampling gas cooler 2, the gas distributor 3, the first manual on-off valve 4, the check valve 9, the water collector 13, the first automatic on-off valve 8, the large particle filter 31, pressure detection gauge 5, pressure signal conversion display instrument 6, gas circulation pump 29, second automatic switch valve 8, check valve 9, second manual switch valve 4 and return gas dryer 16, and in Multiple nitrogen acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com