Lever feedback electrohydraulic servo mechanism

An electro-hydraulic servo and feedback technology, which is applied in the field of servo mechanisms, can solve the problems of poor stability, poor reliability, and low oil interference resistance of electro-hydraulic servo valves, and achieve high work safety, high positioning accuracy, and oil resistance. The effect of strong pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

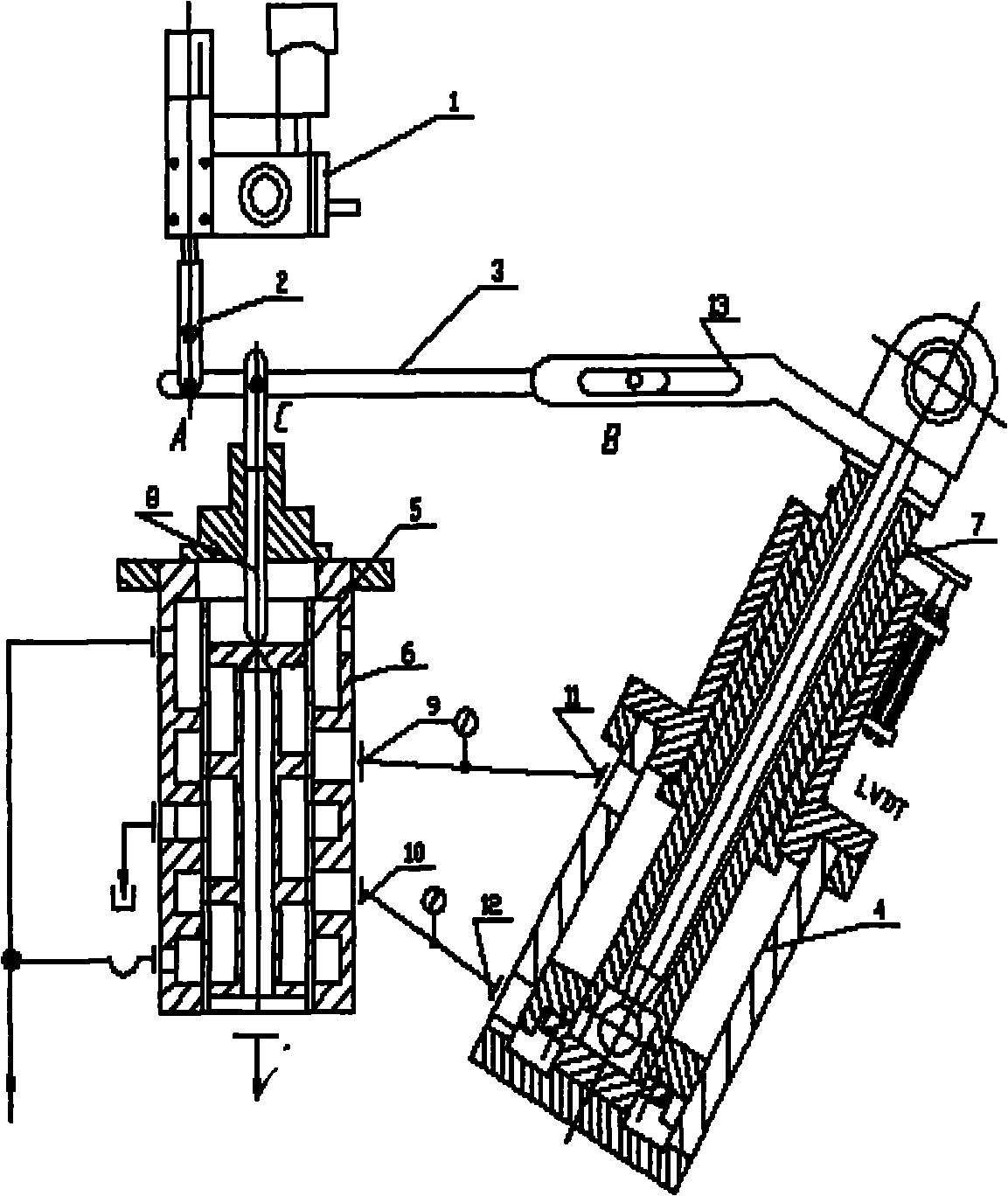

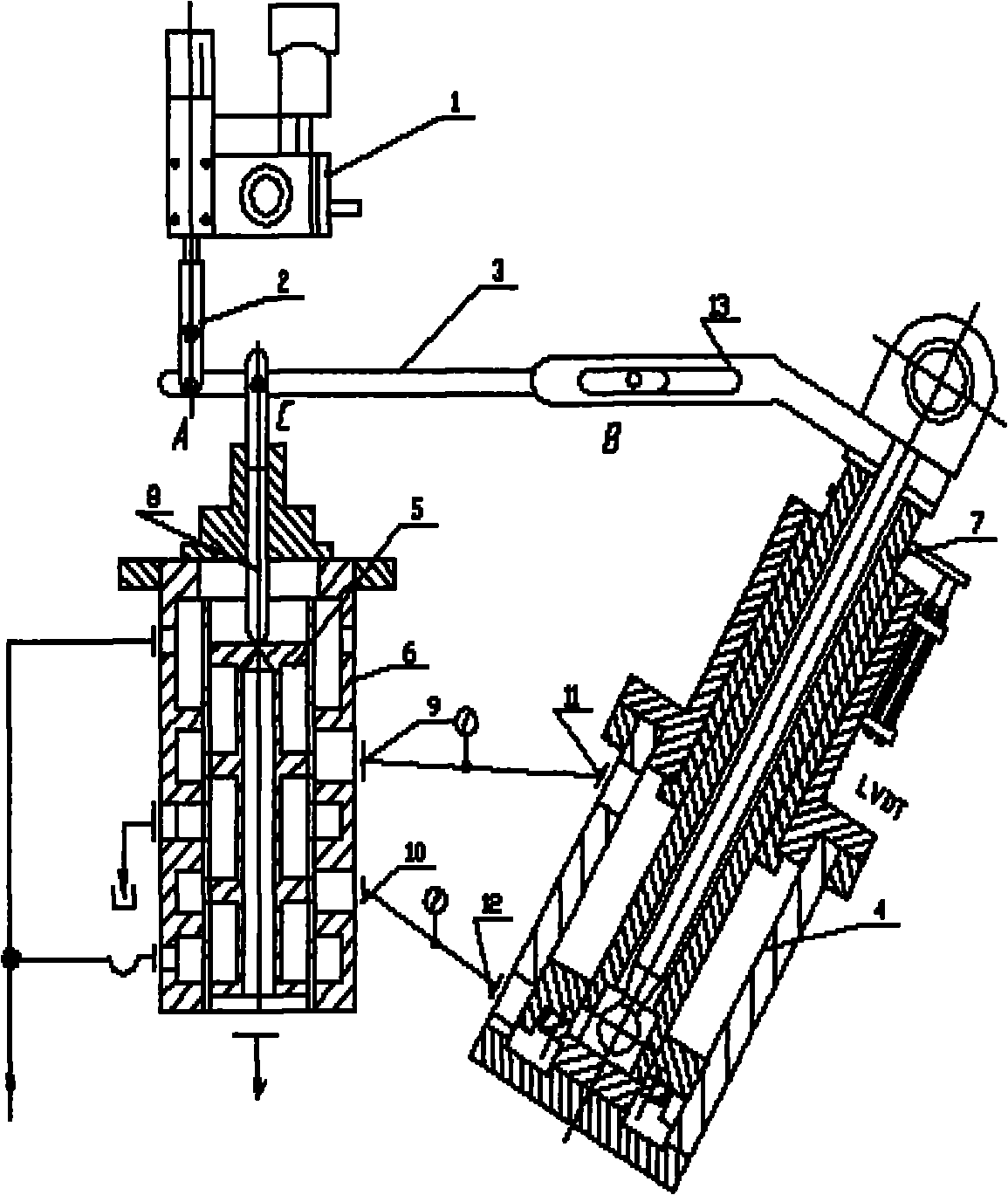

[0009] It has electro-hydraulic actuator 1, lever 3, cylinder 4 and throttle 6. One end of the lever 3 is hinged A with the output shaft 2 of the electro-hydraulic actuator 1, the other end of the lever is connected B with the cylinder piston rod 7 through a sliding hinge 13, the lever is hinged C with the control connecting rod 8 through a hinge, and the hinge point C is located at the hinge point Between A and B, the specific position of the hinge point C depends on the ratio of the maximum stroke of the cylinder piston rod 7 to the maximum output displacement of the electro-hydraulic actuator 1. In this embodiment, the maximum stroke of the cylinder piston rod 7 is greater than that of the electro-hydraulic actuator 1 The maximum output displacement, so the hinge point C is closer to the hinge point A, the control link 8 is connected to the upper part of the wrong throttle slide valve 5, the lower end of the wrong throttle slide valve is subjected to the upward force of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com