Guy-wire-knockout electric connector and guy-wire-knockout electric connector assembly

An electrical connector, detachable technology, applied in the parts, connections, electrical components and other directions of the connecting device, can solve the problems of laborious insertion, high manufacturing cost, complicated structure of the steel ball slot, etc. Easy and reliable removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

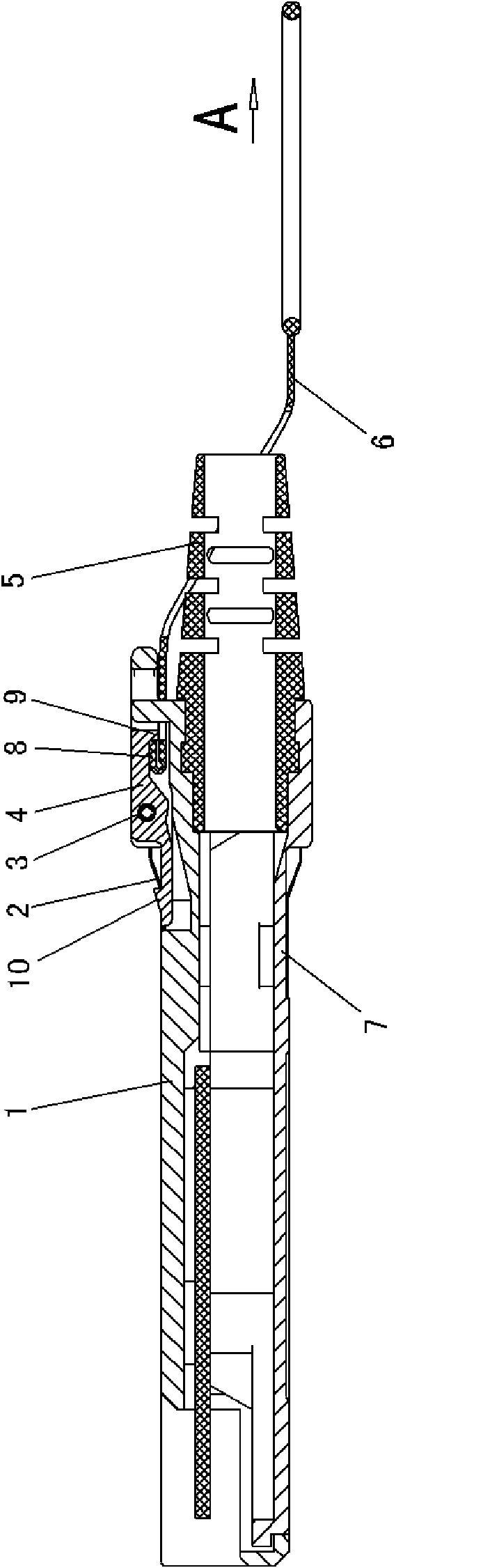

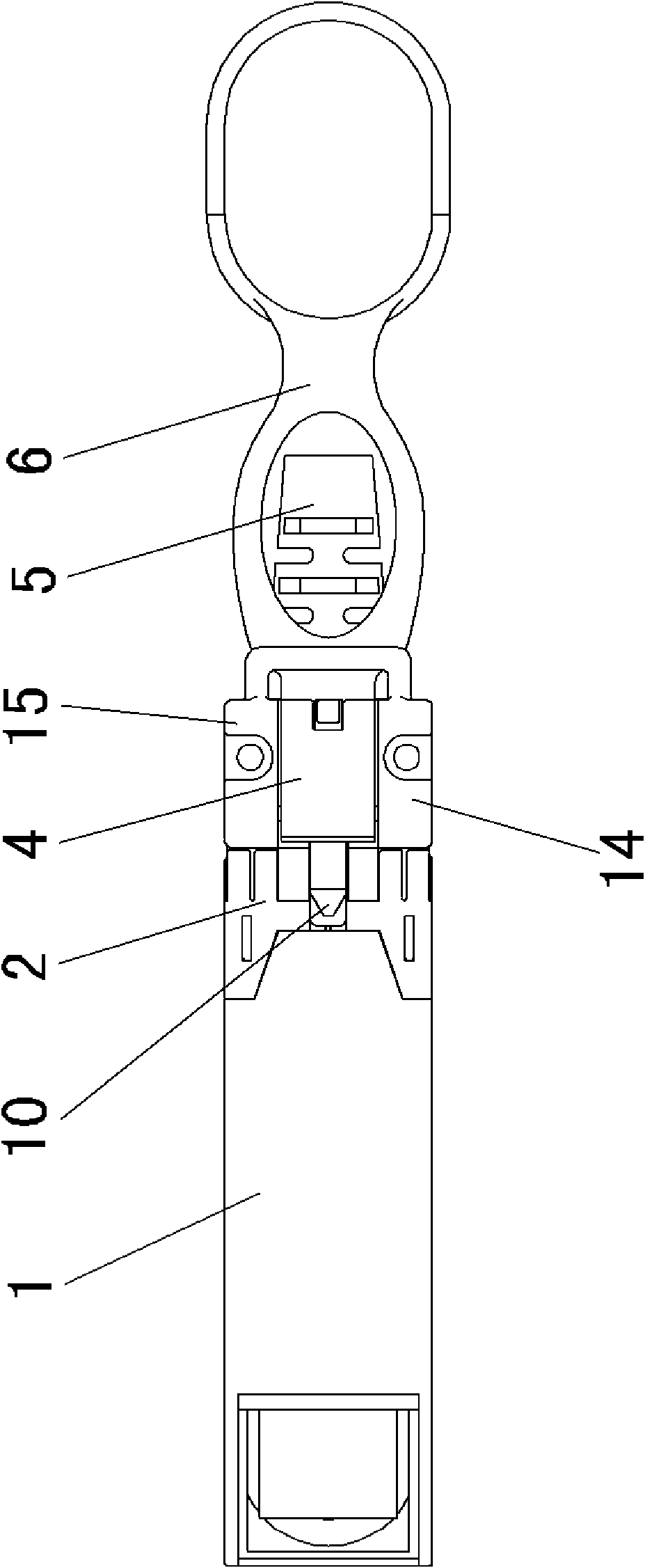

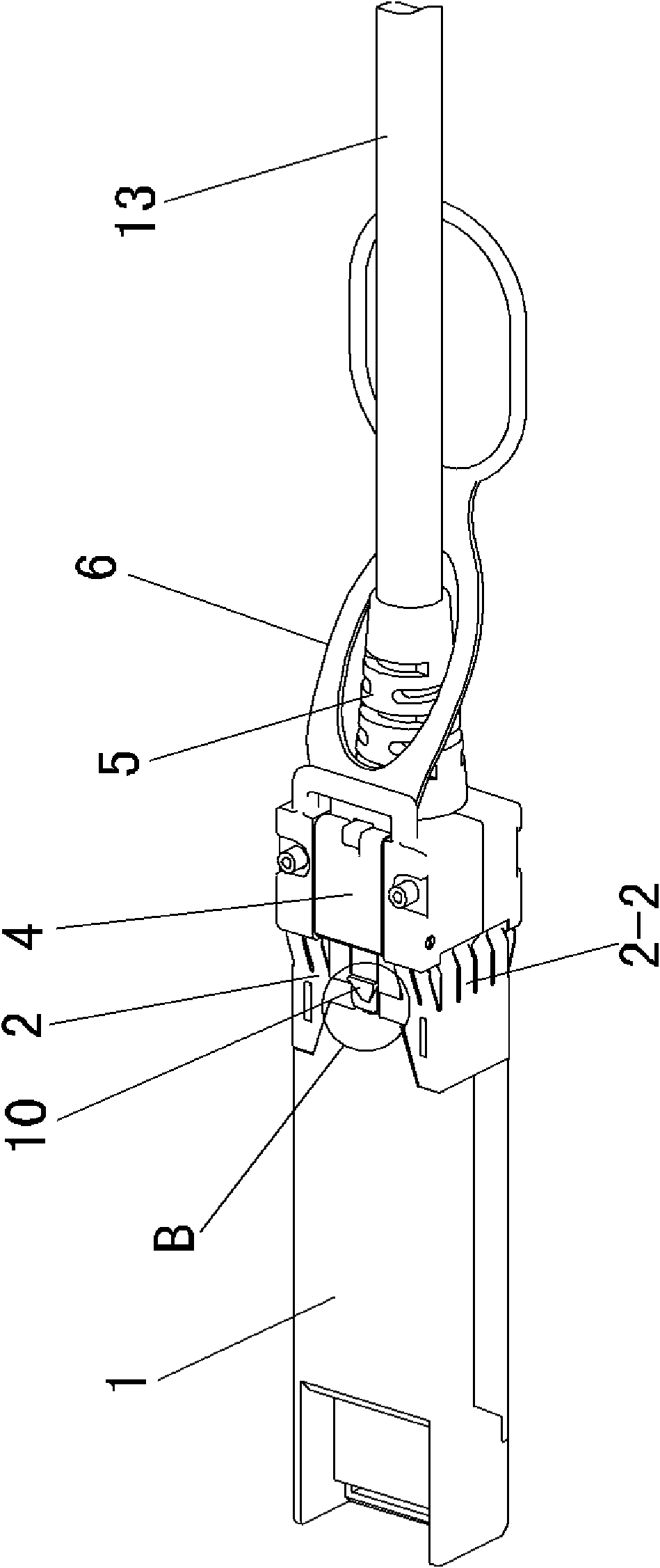

[0024] like Figure 1 to Figure 7 As shown, a specific embodiment of the pull-out connector of the present invention is a SFP high-speed electrical module, which is mated with a cage socket 11 when in use. The combination of the SFP high-speed electrical module and the cage socket 11 forms a pull-out connector assembly.

[0025] The cage socket 11 is a hollow cage body with an opening at the insertion end, and an everted arc-shaped shrapnel 11-1 is provided on the surrounding side walls near the opening of the insertion end. The SFP module includes a connector housing composed of upper and lower housings 1, 7, the housing has a mating end corresponding to the cage socket 11 and a cable inlet end for the insertion of the cable 13, figure 1 , figure 2 No cables are shown in . A sheath 5 is also connected to the cable entry end of the SFP module housing. A pair of shoulders 14, 15 are provided on the surface of the upper case 1 of the SFP module, and a lever lock arm 4 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com