Rough grinding tool

A technology of rough grinding and abrasive tools, applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve problems such as cracking of the substrate carrying abrasives, and achieve the effect of increasing processing power and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

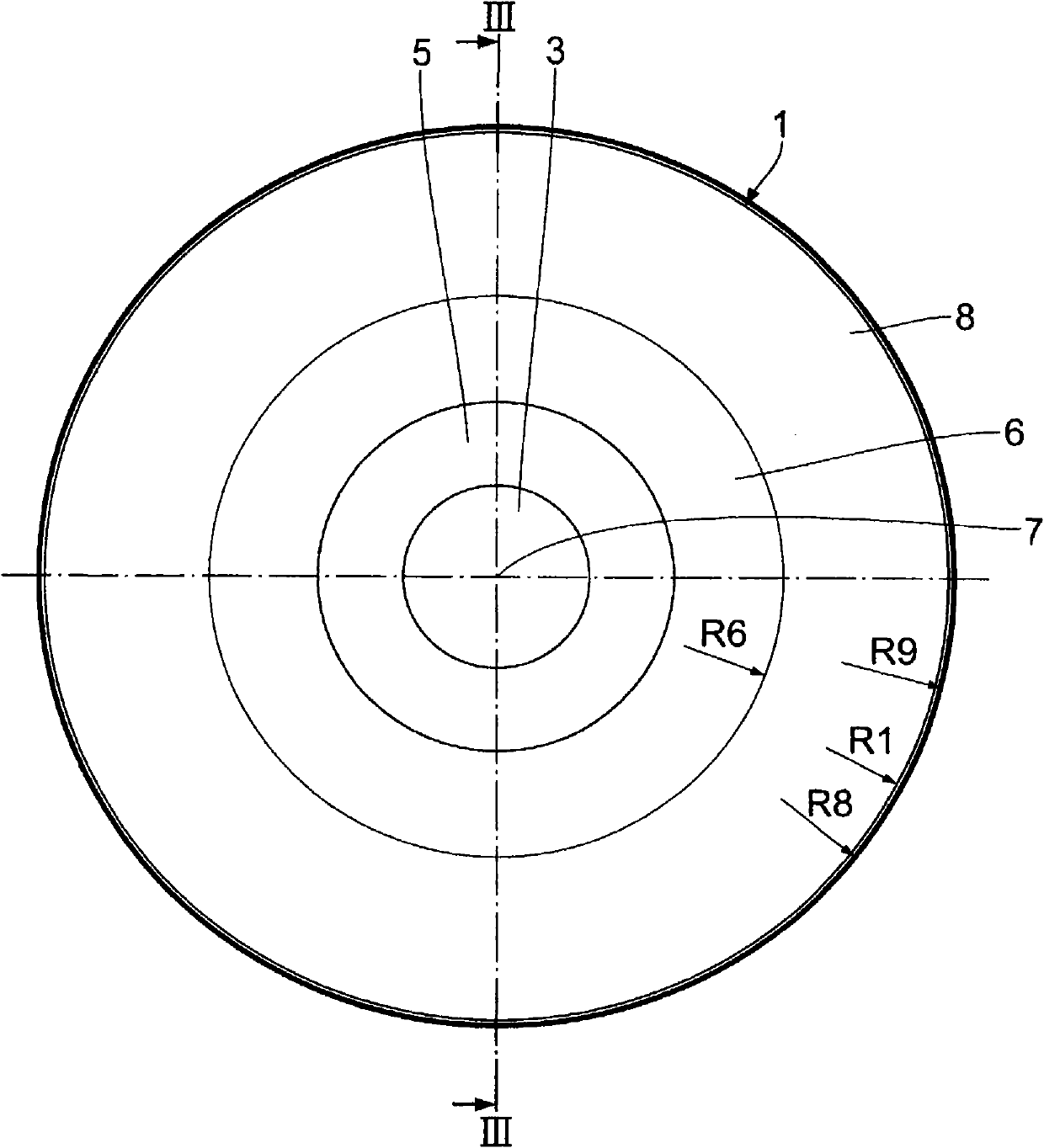

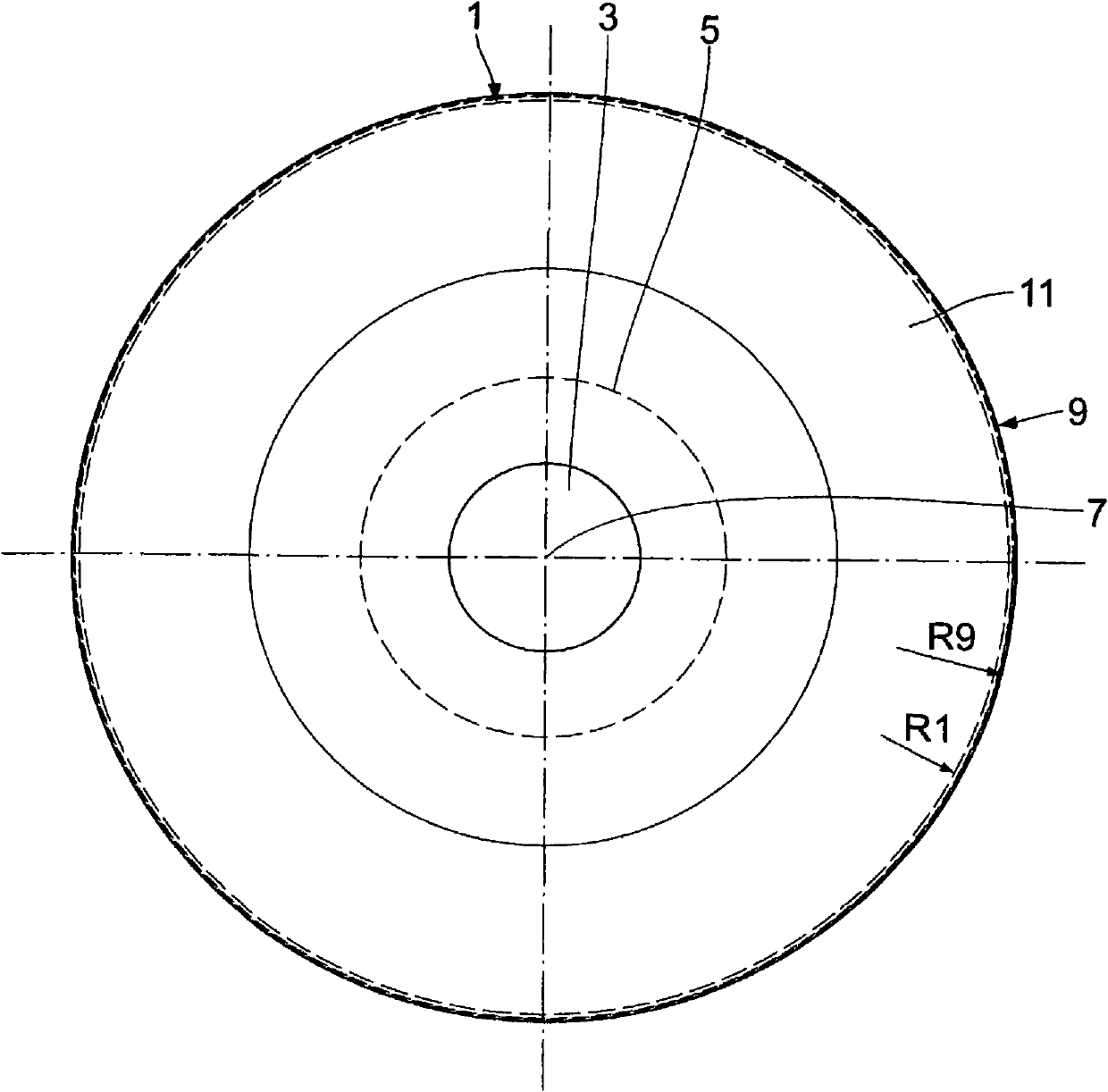

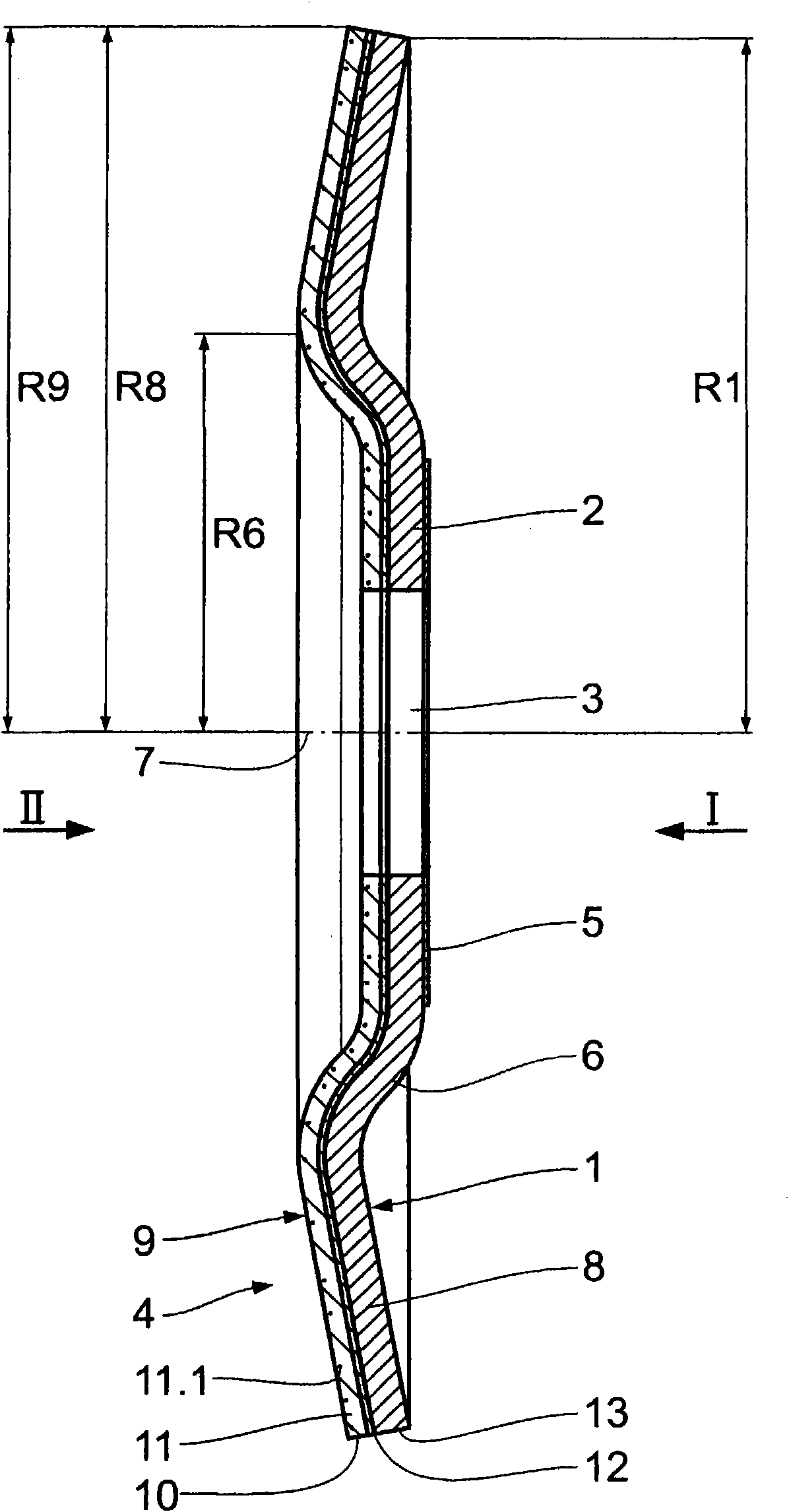

[0027] exist Figure 1 to Figure 3 The rough grinding tool shown in has a support plate 1 made of compressed glass fibers impregnated with phenolic resin in a conventional manner and has a flat, annular clamping region 2 in which A likewise circular hole 3 in the tight area is designed to receive the drive shaft of the drive. The annular clamping region 2 surrounding the bore 3 is provided with a metal ring 5 on the rear side of the carrier plate 1 facing away from the grinding side 4 . The clamping area 2 is adjoined by a curved area 6 which is also annular and rises radially with respect to the axis 7 of the bearing plate 1 towards the grinding side 4 . The annular grinding region 8 adjoins the bending region 6 and is inclined radially opposite to the bending region 6 relative to the axis 7 , in particular radially outwardly away from the grinding side 4 relative to the axis 7 . Such a construction of the support plate 1 is generally known and conventional.

[0028] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com