Planar illumination device

A lighting device and plane technology, which is applied to lighting devices, fixed lighting devices, and components of lighting devices, etc., can solve the problems of bright lines and leakage of illumination light at the connecting part, so as to reduce light leakage and suppress the generation of bright lines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0023] Modification

no. 2 approach

[0025] first embodiment

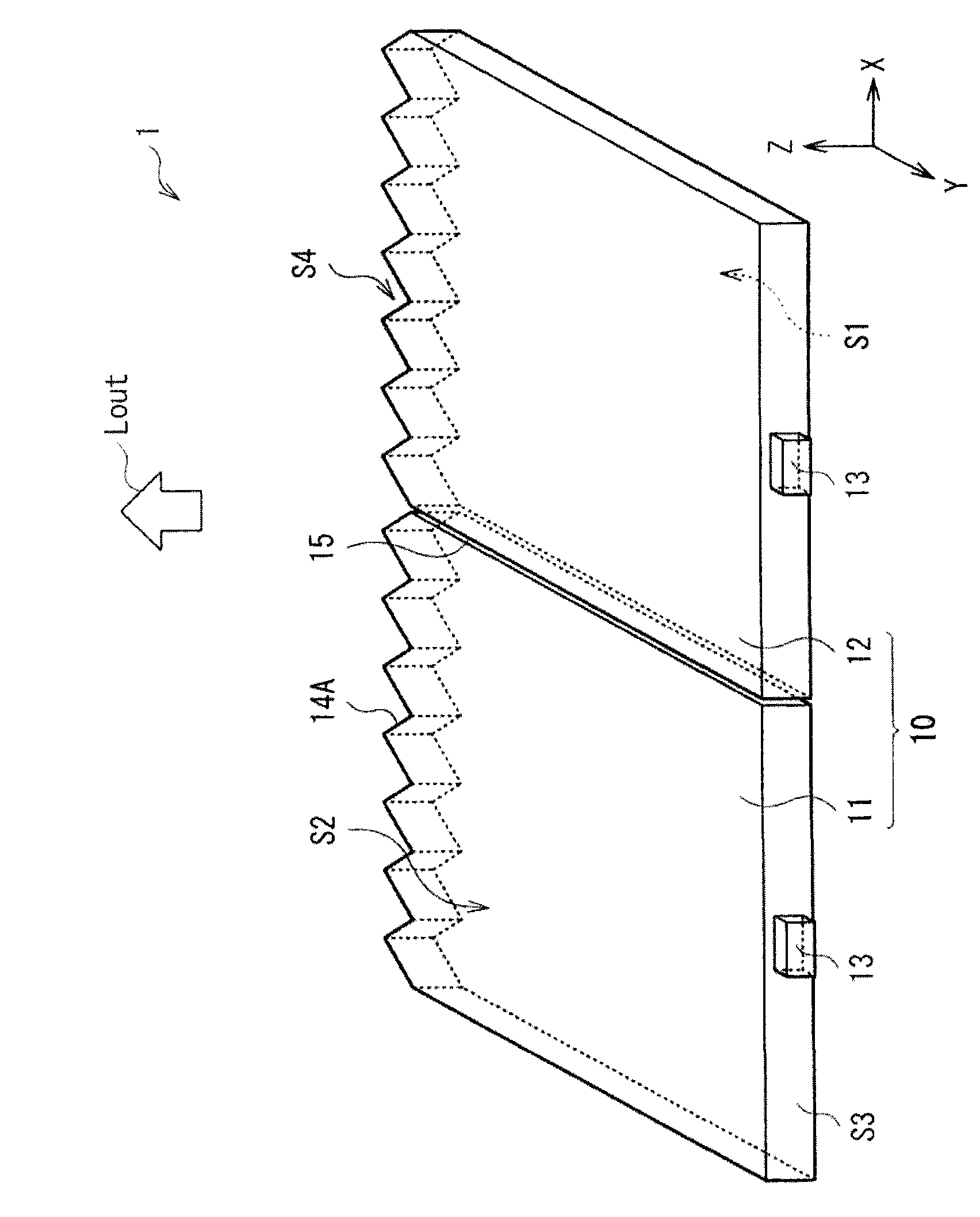

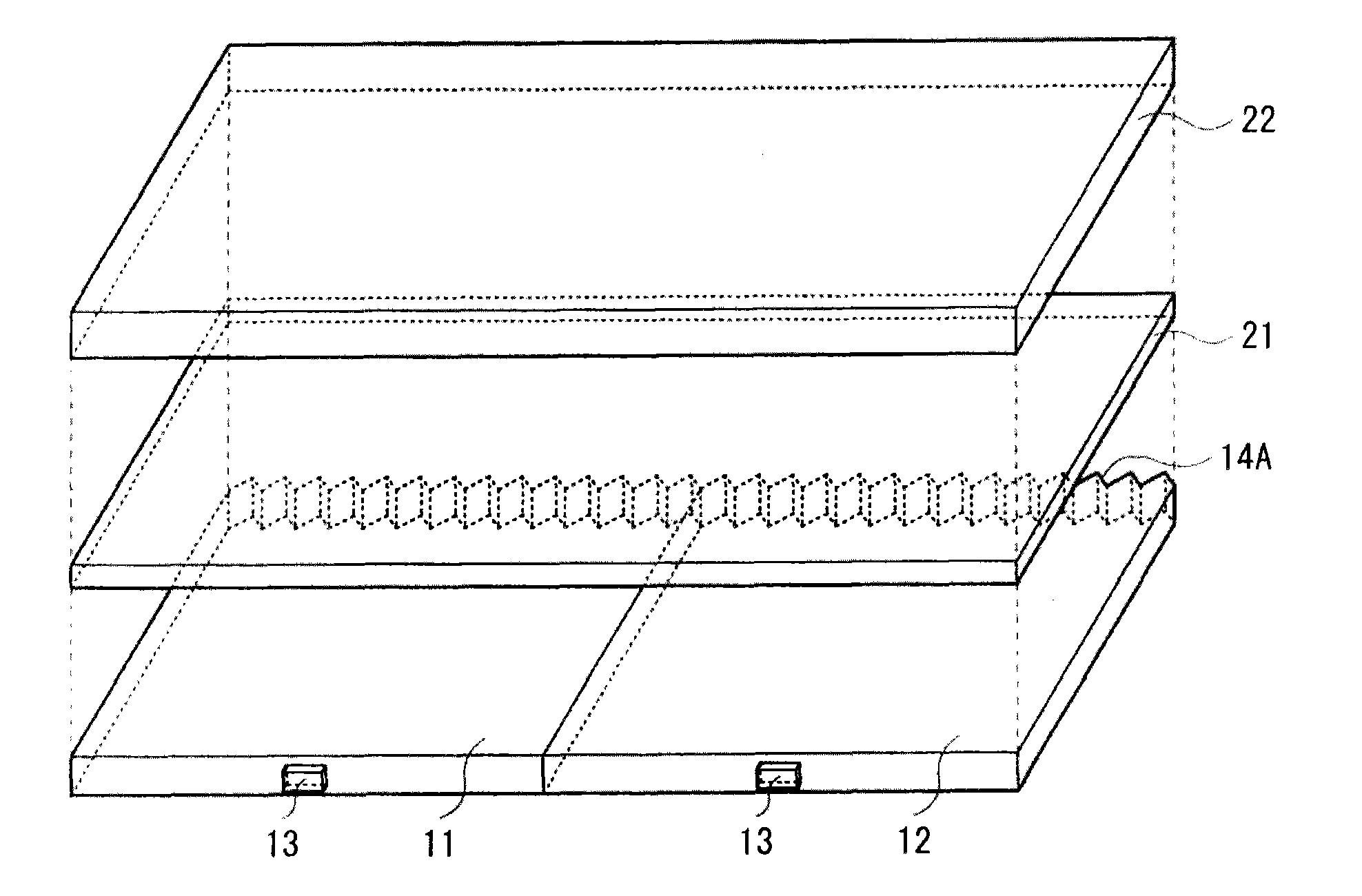

[0026] figure 1 is a perspective view showing the configuration of a main part of the planar lighting device 1 according to the first embodiment of the present invention. For example, the planar lighting device 1 is used as a backlight of a liquid crystal display or the like, and in the planar lighting device 1 , the light guide plate 10 is formed by closely arranging a plurality of unit light guide plates in one row or two or more. Here, the light guide plate 10 composed of two unit light guide plates 11 and 12 will be described below.

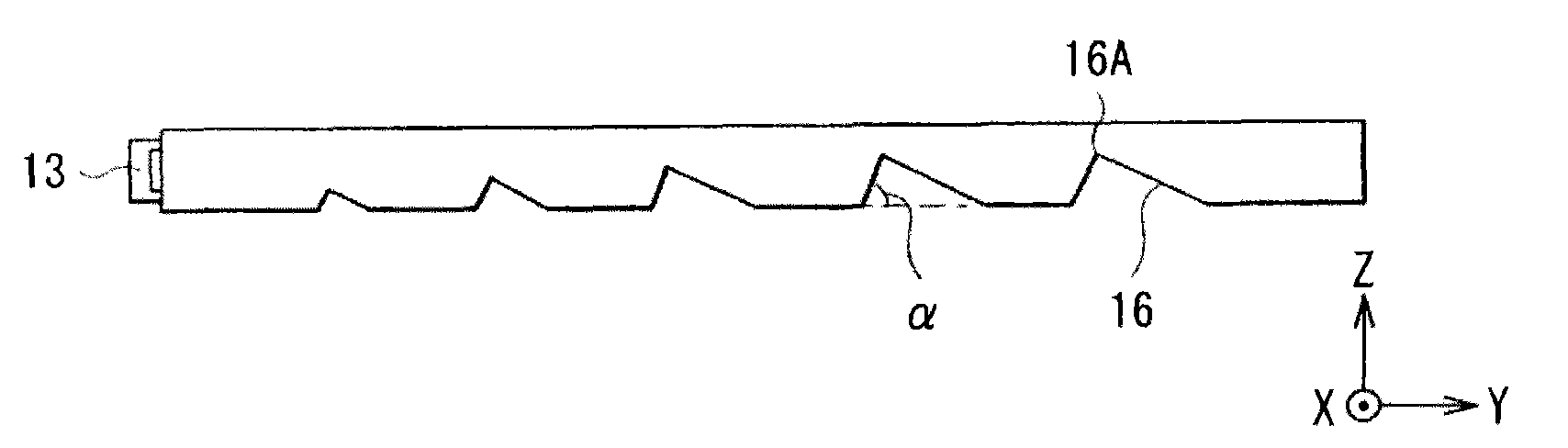

[0027] In the planar lighting device 1 , the light source 13 is arranged on the side S3 (first side) of each of the unit light guide plates 11 and 12 along the arrangement direction (X direction) of the unit light guide plates 11 and 12 . The unit light guide plates 11 and 12 each have, for example, a rectangular planar shape, and the rear surface of each unit light guide plate 11 and 12 is a reflective surface S1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com