Remote fault detection and processing system of DC power supply screen

A DC power supply screen and fault detection technology, applied in the direction of power supply testing, etc., can solve problems such as abnormal operation and failure causes cannot be accurately found, unable to reflect the detailed information of the DC system, less professional and technical level of maintenance personnel, etc., so as to shorten the maintenance time. , The effect of preventing modification of the operation of the DC panel and reducing the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the utility model is further described.

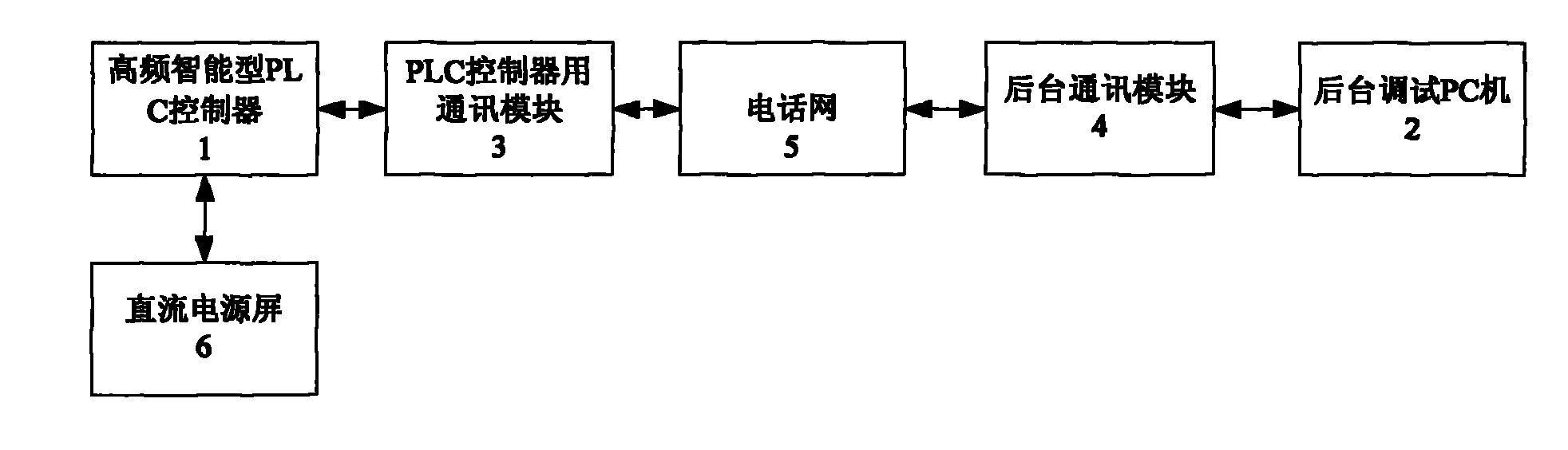

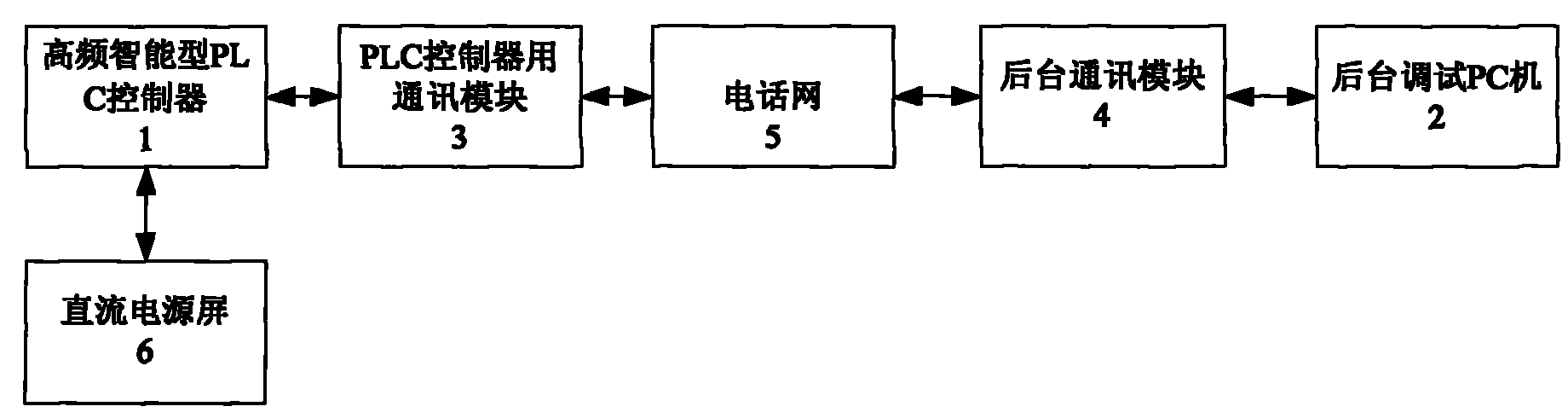

[0019] Such as figure 1 As shown, a remote fault detection and processing system for a DC power panel, including:

[0020] A high-frequency intelligent PLC controller 1 with four remote functions connected to the DC power panel 6 is used to collect all operating parameters and operating information of the DC power panel, and to perform automatic control of the DC panel;

[0021] The background debugging PC 2 is used to receive all parameters of the on-site DC power supply screen, perform fault judgment and processing on the corresponding information, and send fault processing commands at the same time;

[0022] The communication module 3 for the PLC controller and the background communication module 4 are used for remote communication between the high-frequency intelligent PLC controller 1 and the background debugging PC 2;

[0023] Described high-frequency intelligent PLC contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com