Method and device for rapidly detecting and classifying defects of glass image

A defect detection and classification method technology, applied in image analysis, image data processing, instruments, etc., can solve problems such as difficult defect detection and classification tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0152] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

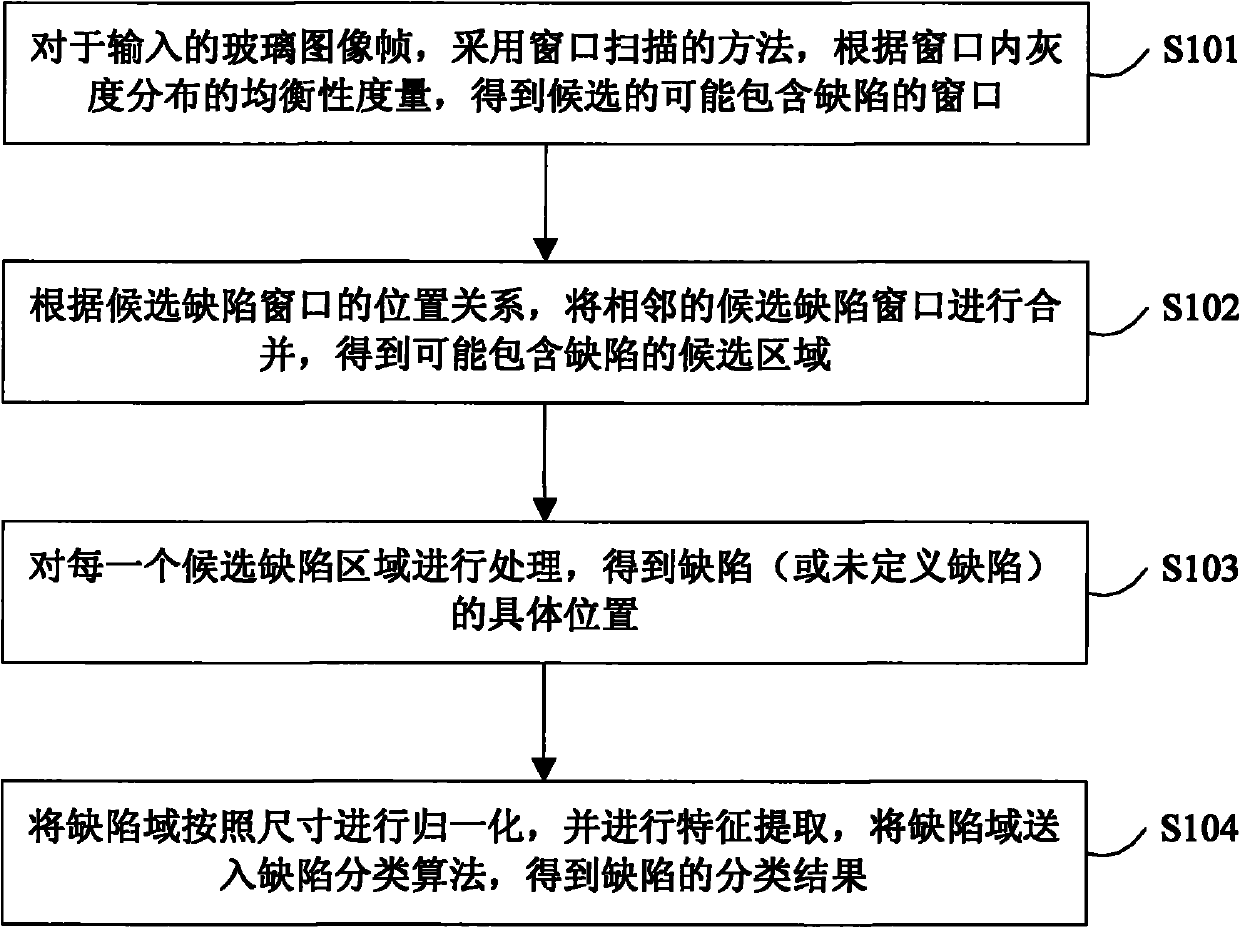

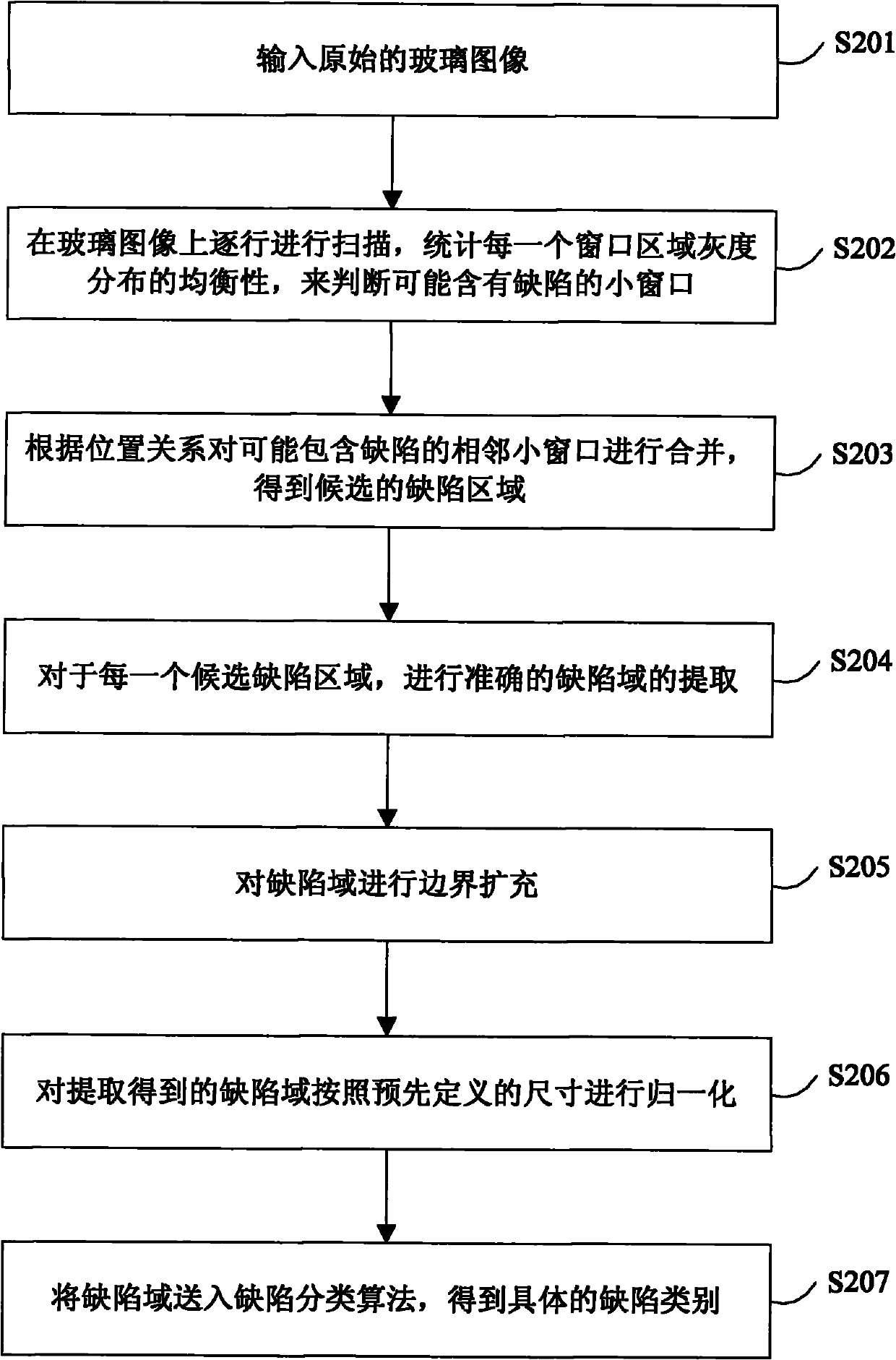

[0153] Such as figure 1 The above is a flow chart of the fast glass image defect detection and classification method of the present invention. The method is a fast and robust defect detection and classification method suitable for glass original sheets containing noise. The method can be divided into two Stages: The first is the defect domain detection stage; the second is the defect classification stage. Specifically include the following steps:

[0154] Step 101, for the input glass image frame, adopt the method of window scanning, according to the measure of the balance of the gray scale distribution in the window, obtain the candidate window (candidate defect window) that may contain defects;

[0155] Step 102, according to the positional relationship of the candidate defect windows, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com