Tower ground wire universal lifting mechanism

A lifter and ground wire technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of low work efficiency, difficult installation of wire clips, long power failure time, etc., to improve work efficiency, facilitate high-altitude operations, and improve working conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

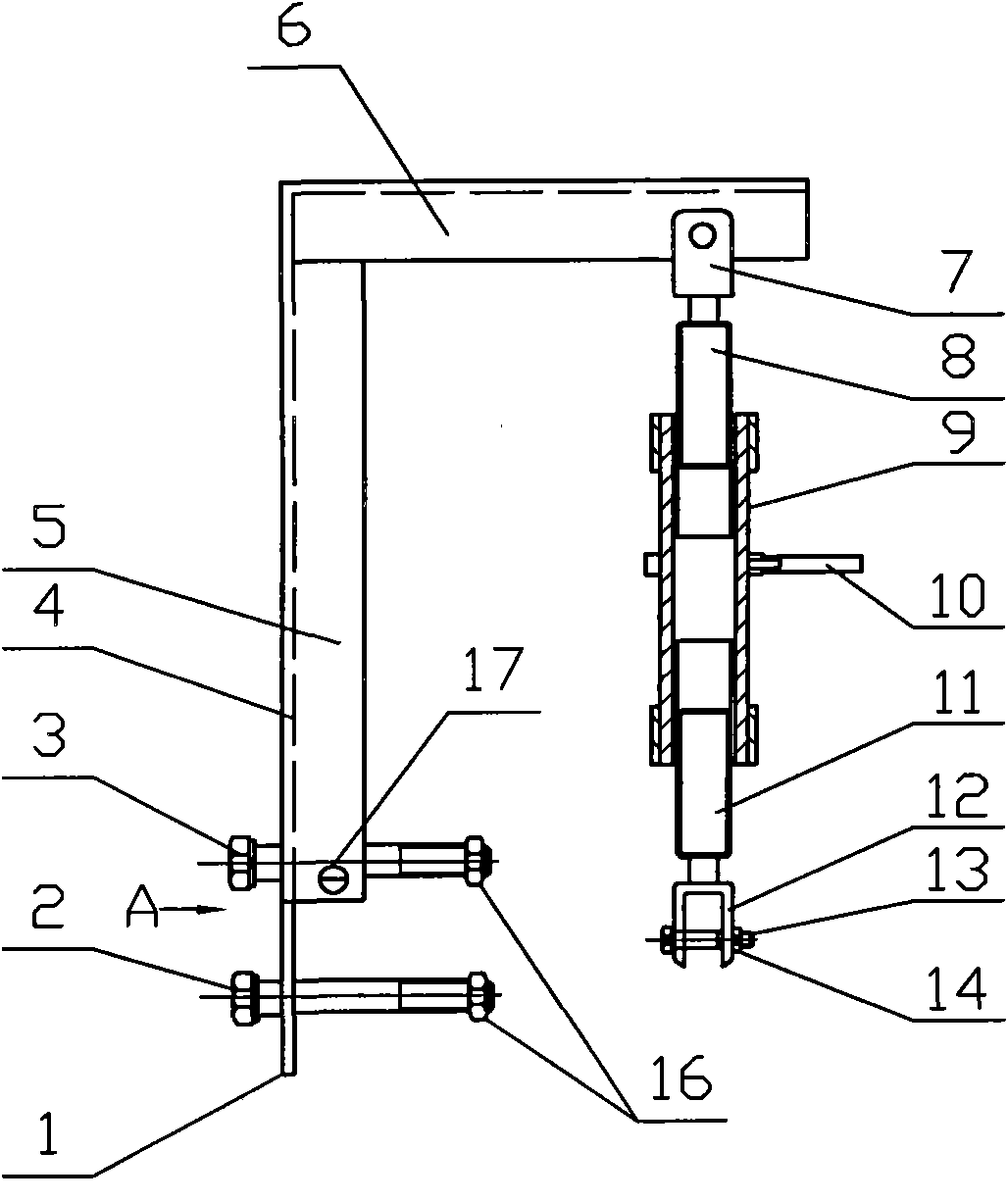

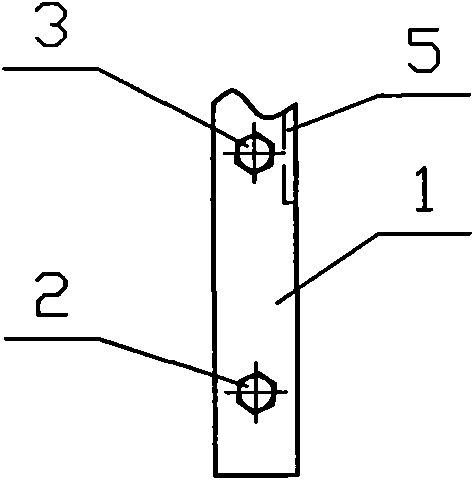

[0017] Depend on figure 1 , figure 2 The shown universal lifter for a tower ground wire includes a vertically arranged lifting rod 9, a fixed bracket, an upper connecting rod and a lower connecting rod. A handle 10 is horizontally provided on the outer surface of the middle part of the lifting rod 9, and the upper connecting rod includes the stud part 8 of the joint 7 fixed on the top, and the lower connecting rod includes the stud part 11 of the terminal provided at the bottom; The column part 8 is assembled in the upper end of the lifting rod 9, the stud part 11 of the lower connecting rod is assembled in the lower end of the lifting rod 9, and the screw threads of the two stud parts 9, 11 of the upper and lower connecting rods are in opposite directions. The fixed support includes a column and a cross bar 6 fixed on the top of the column, and the joint 7 is hinged at the end of the cross bar 6 . The column and the cross bar 6 are all angle irons, and the angle irons are ...

Embodiment 2

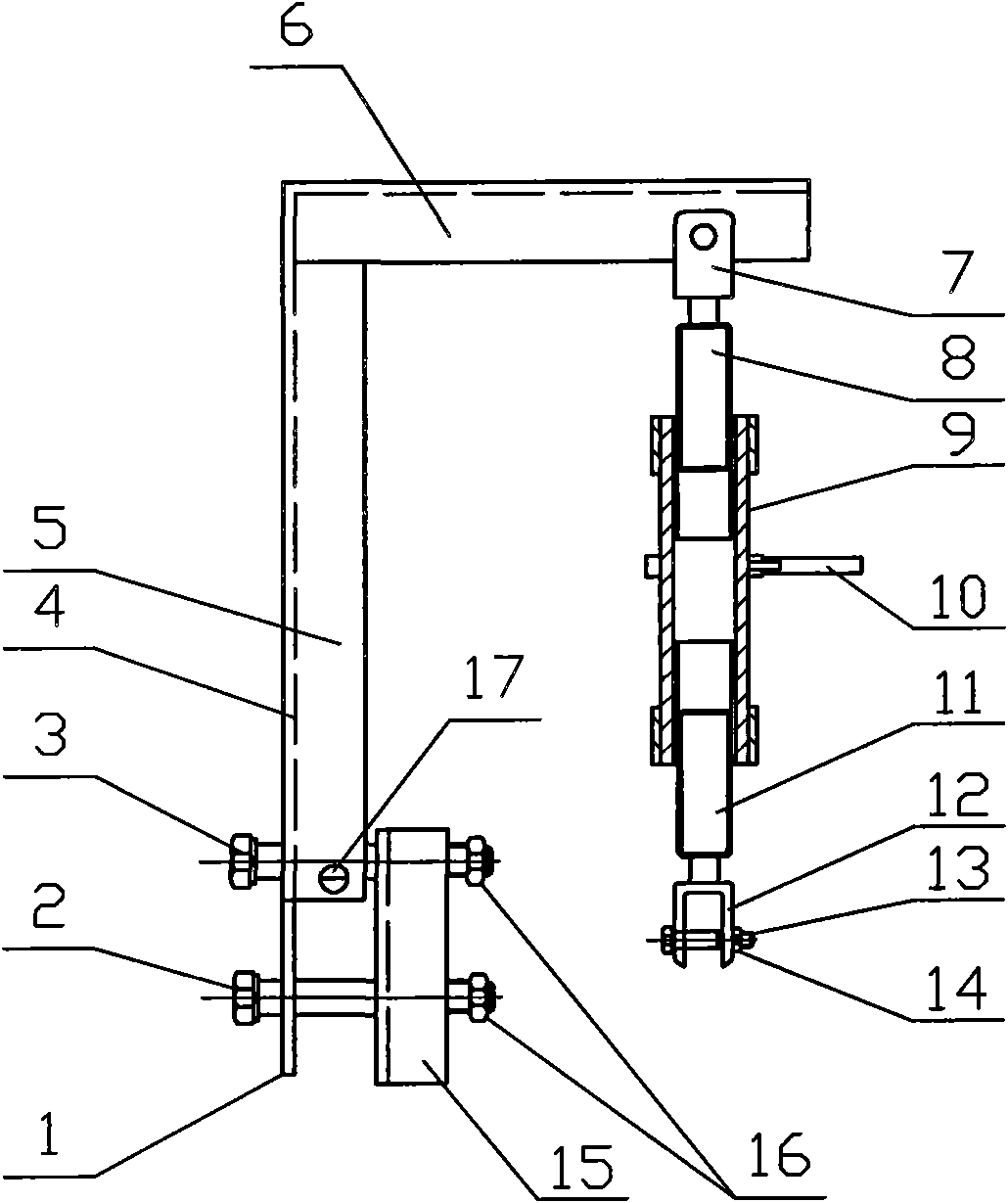

[0020] Depend on image 3 The difference between the universal riser for pole tower ground wire shown in Embodiment 1 is that it includes an auxiliary reinforcing iron 15 arranged on the side of the extension part 1, and the auxiliary reinforcing iron 15 is provided with upper and lower fixing holes. Corresponding to the two fixing holes respectively, the two bolts 3 and 2 are inserted through the auxiliary reinforcement iron 15 and the extension part 1 vertically and horizontally respectively, and the ends of the bolts 3 and 2 are provided with nuts 16 . The auxiliary reinforcing iron 15 is also an angle iron, and the fixing hole is arranged on a vertical surface of the angle iron of the auxiliary reinforcing iron 15 .

[0021] This embodiment is used when the fixed bracket is stressed, and the auxiliary reinforcing iron 15 can increase the bending and tensile strength and improve the safety factor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com