Automatic core assembling and setting clamp

A technology of core assembly and core clips, applied in the direction of cores, manufacturing tools, casting molding equipment, etc., can solve problems such as deformation, increased core storage costs, and large transportation tools, so as to reduce costs, improve production efficiency, and ensure dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The structure and use of the automatic core assembly and core-setting fixture of the present invention will be further described with reference to the accompanying drawings.

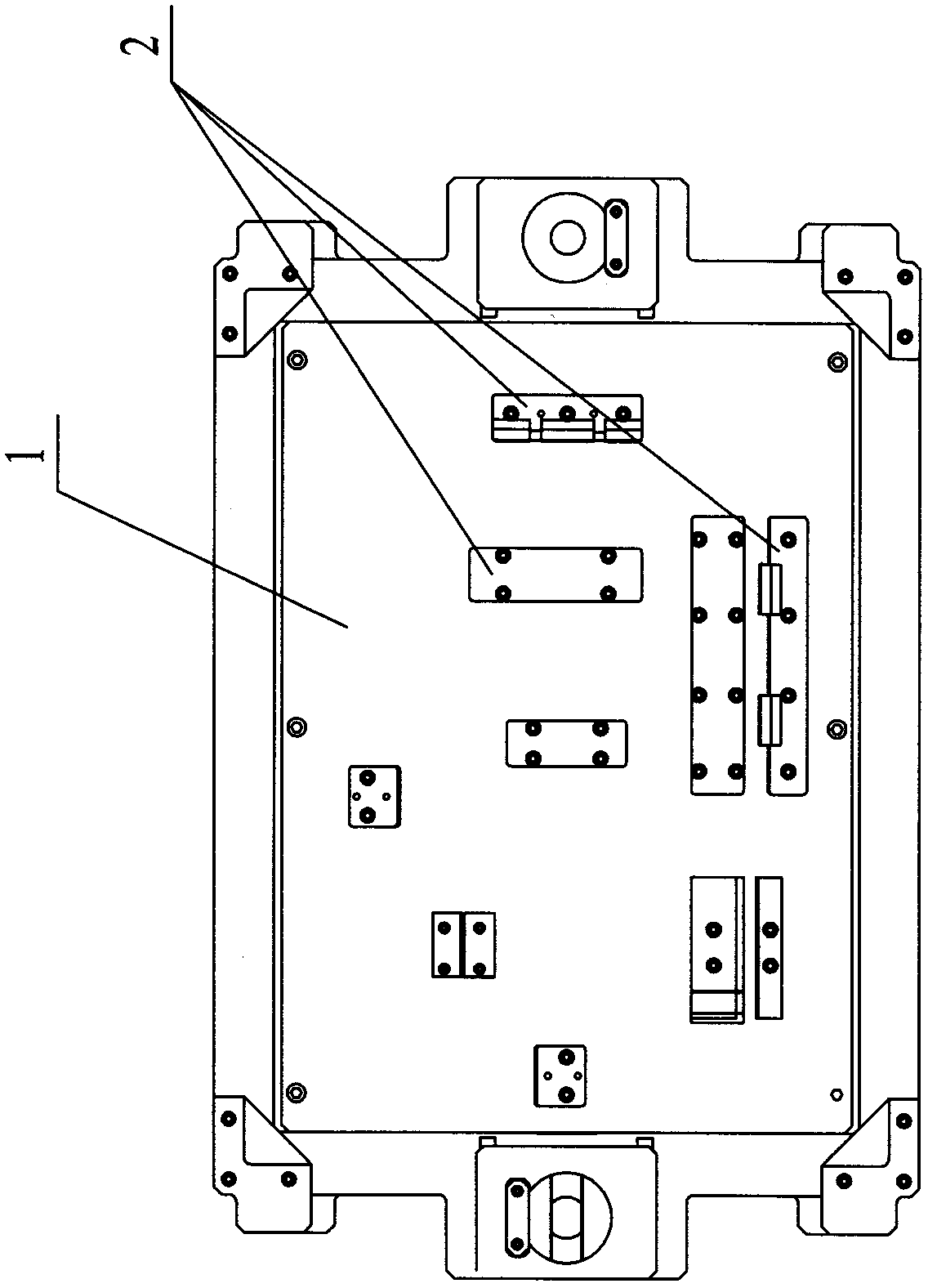

[0013] Such as figure 1 As shown, the traditional core setting fixture only includes the base 1 and the positioning block 2, and has no automatic core assembly function.

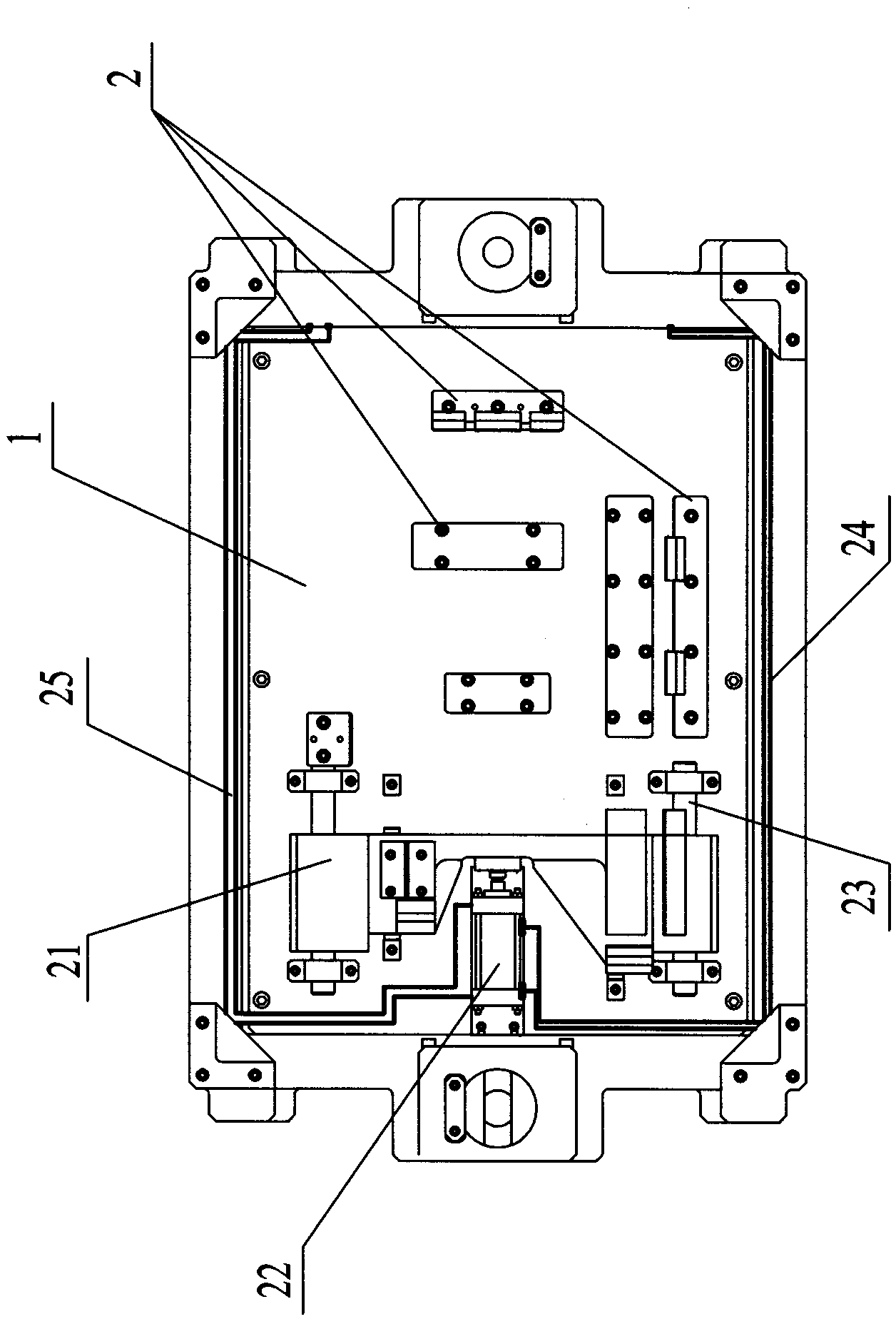

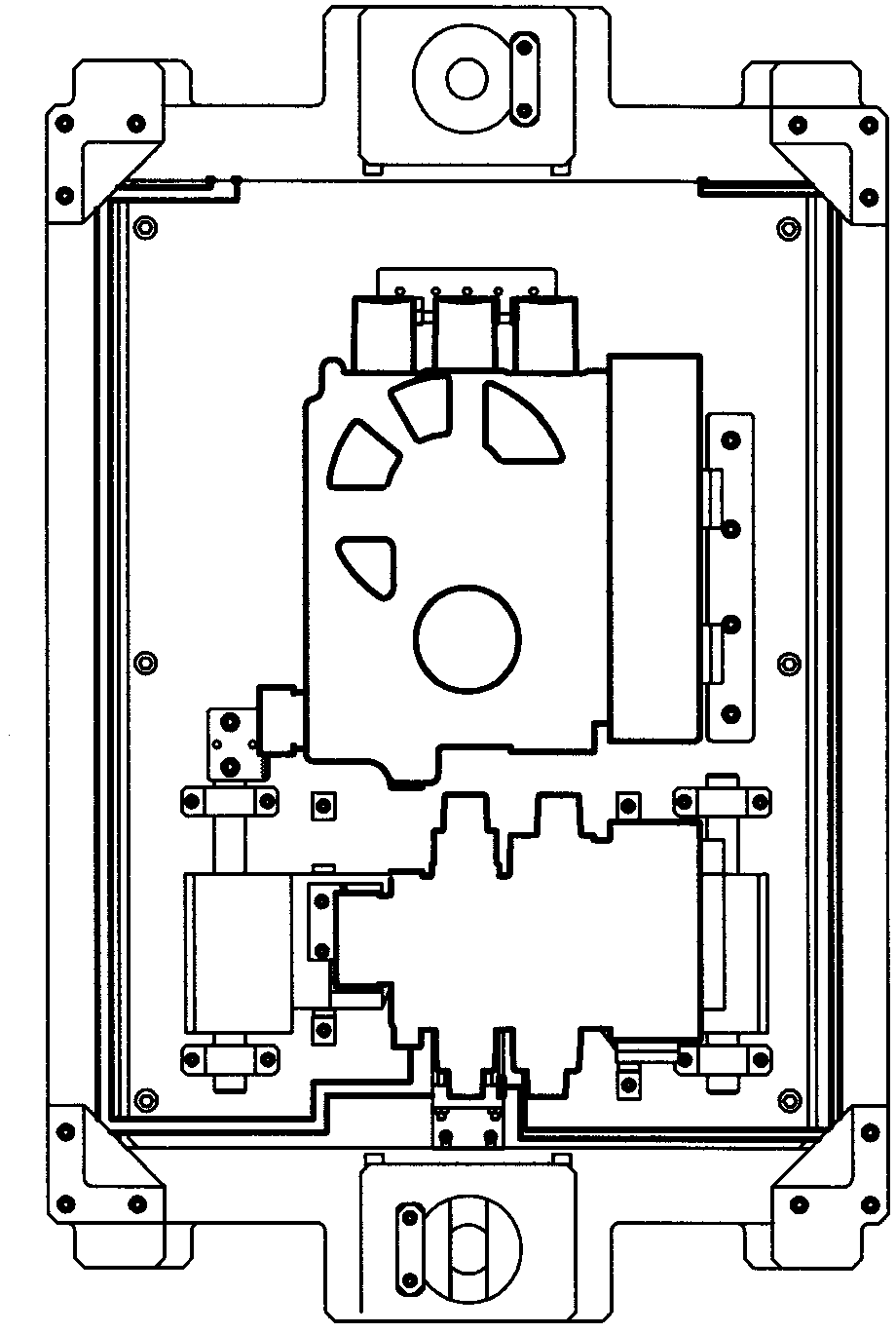

[0014] Such as figure 2 As shown, an automatic core assembly and core lowering fixture includes a lower core spreader and a lower core mold. The lower core mold includes a base 1 and a positioning block 2. The positioning block 2 is fixed on the base 1, which further includes Drive slider 21, core assembly cylinder 22, guide rod 23; core assembly cylinder 22 and guide rod 23 are fixed on base 1; core assembly cylinder 22 is connected to drive slider 21; drive slider 21 is driven by core assembly cylinder 22 , Move linearly along the guide rod 23, push the small core, and complete the core assembly work.

[0015] A signal line 24 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com