Off-highway dump truck for reducing abrasion and prolonging service life of plate spring

A non-highway and dump truck technology, applied in the direction of springs, leaf springs, springs/shock absorbers, etc., can solve the problems of reducing pressure, wear resistance below, and the longest leaf spring is easy to break, so as to improve life and impact force The effect of reducing and prolonging the life of leaf springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

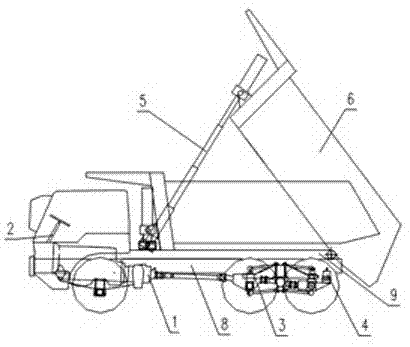

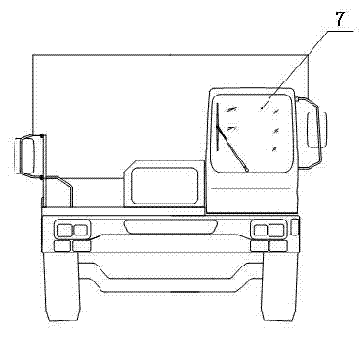

[0066] Example 1 as figure 1 and figure 2 As shown, this kind of non-highway dump truck that reduces wear and improves the service life of the leaf spring includes a car body, a frame, a power system, a transmission system, a car box, tires, and a braking system. Its power system 1 is connected to the On the main frame 8, the steering system 2 is connected to the left front outside of the main frame 8, the suspension system 3 is connected below the main frame 8, the braking system 4 is connected to the inside and outside of the main frame 8, and the lifting system The hydraulic cylinder of 5 is connected to the front end of the subframe 9 and the front plate of the cargo box 6 through the oil cylinder connecting seat, the cargo box 6 is connected to the subframe 9, and the subframe 9 is connected to the main frame through a bracket and a connecting plate 8 above, the cab 7 is connected to the left front of the main frame through brackets. It designs a new type of leaf sprin...

Embodiment 2

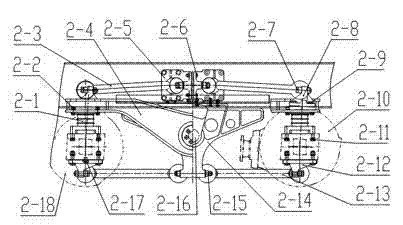

[0082] Embodiment 2 is basically the same as Embodiment 1, and the difference is that its suspension is a balance beam suspension such as diagram 2-1 As shown, there are four rubber main springs 2-1, two of which are connected to the two ends of the equalizing beam 2-4 on the left side of the vehicle frame 2-23 through bolts 2-2, and the other two are connected to the The two ends of the equalizing beam 2-4 on the right side of the vehicle frame 2-23, and the bottom of the four rubber main springs 2-1 are respectively connected to the axle housing processing surfaces of the middle axle 2-18 and the rear axle 2-10 through bolts 2-11 The middle part of the balance beam 2-4 is connected to the two ends of the balance shaft 2-16 with rubber bearing 2-19, rubber bearing cover 2-20, and bolt 2-21, and the balance shaft 2-16 is fixed on the balance shaft support 2-14 Among them, the two balance shaft brackets 2-14 are respectively connected to the vehicle frame 2-23 through bolts 2-...

Embodiment 3

[0083] Embodiment 3 is basically the same as Embodiment 1, and the difference is that its suspension is another kind of suspension structure such as Figure 3-1 As shown, it is the longitudinal distribution diagram of embodiment 3, the upper thrust rod 3-1 and the lower thrust rod 3-13, the middle bridge 3-14 and the support 3-11, and the four balance beams 3-15 pass through the upper thrust rod beam end The connection of support 3-2, upper thrust rod bridge end support 3-4 and lower thrust rod support 3-9 forms two side-by-side four-bar linkages at the front end and rear end of four balance beams 3-15, which can effectively control Longitudinal runout of middle axle 3-14 and rear axle 3-16. The two ends of the four upper thrust rods 3-1 are respectively connected to the upper thrust rod beam end support 3-2 and the upper thrust rod bridge end support 3-4 by two bolts 3-17, and the upper thrust rod beam end support 3-2 is single The limit is connected on four beams 3-15 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com