Assembly type cold-formed steel wall-plate-column damping structure system with U-shaped mild steel damper

A mild steel damper, cold-formed technology, used in infrastructure engineering, walls, earthquake-proof and other directions, can solve the problems of insufficient lateral force resistance, low stiffness of flange joints, and difficulty in achieving rigid connection between columns. Lateral force and energy dissipation capacity, improving joint reliability and stiffness, and solving the effect of insufficient lateral force resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

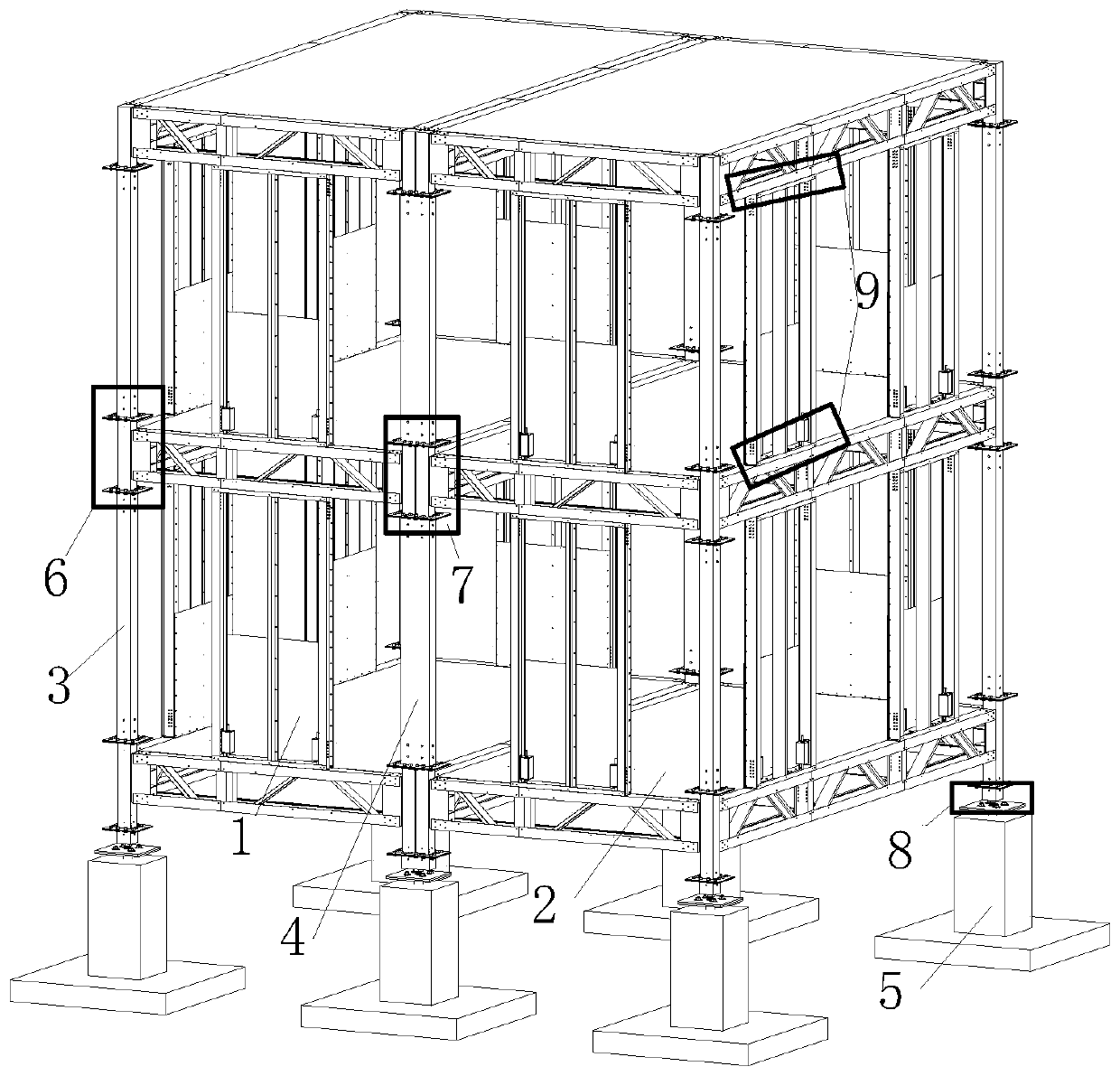

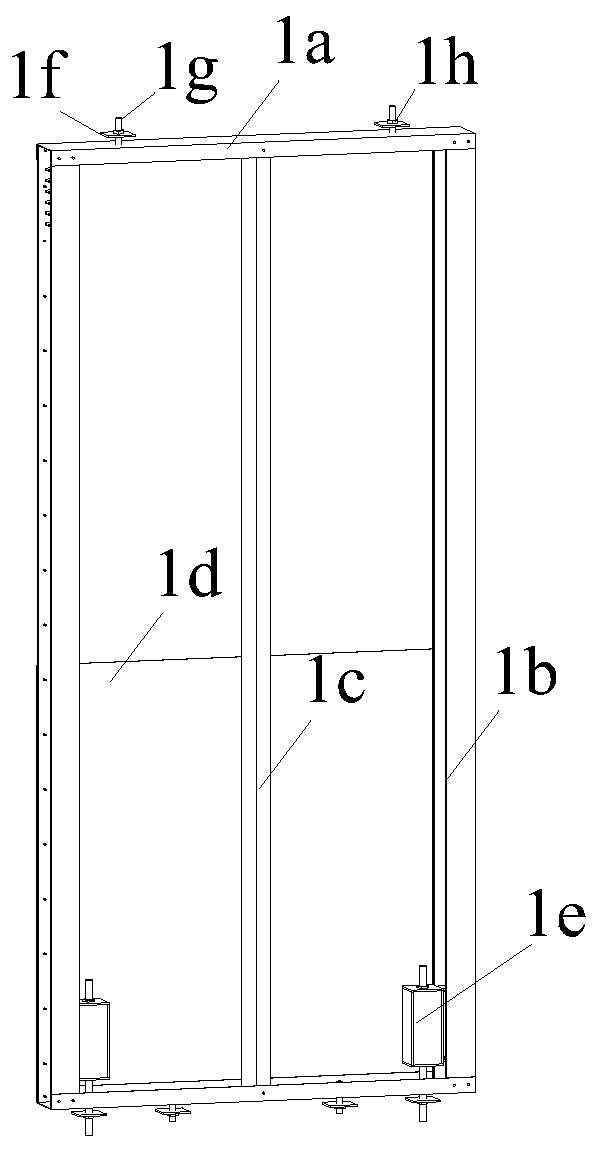

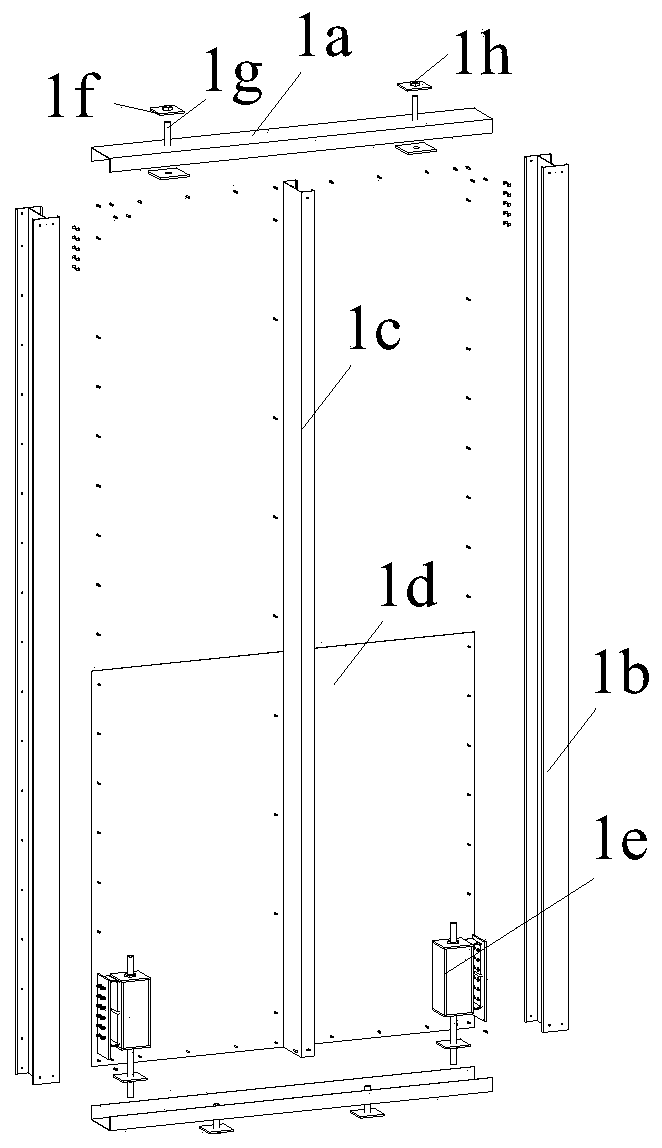

[0039] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and the technical solution of the description:

[0040] The production method of the energy-dissipating wall module with U-shaped mild steel damper:

[0041] Step 1: Design the dimensions according to the drawings in the factory, refer to the attached figure 2 , 3 , cutting and processing the U-shaped steel required for the steel guide rail (1a), the C-shaped steel required for the combined side column (1b), the C-shaped steel required for the center column (1c), and the wall panel (1d);

[0042] Step 2: According to the design technical scheme, the back-to-back C-shaped steel is processed into a combined side column (1b) according to the designed connection method (which can be rivets, self-tapping screws, pull rivets, shot nails, rivetless rivets, etc.), and Through the factory assembly line, the steel guide rail (1a), the combined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com