Electric spiral lifting rod

An electric screw and lifting rod technology, applied in the field of lifting rods, can solve the problems of difficult processing, complex structure, limitation of lifting height and lifting weight, etc., and achieve a concise connection structure, high strength, and excellent reliability and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

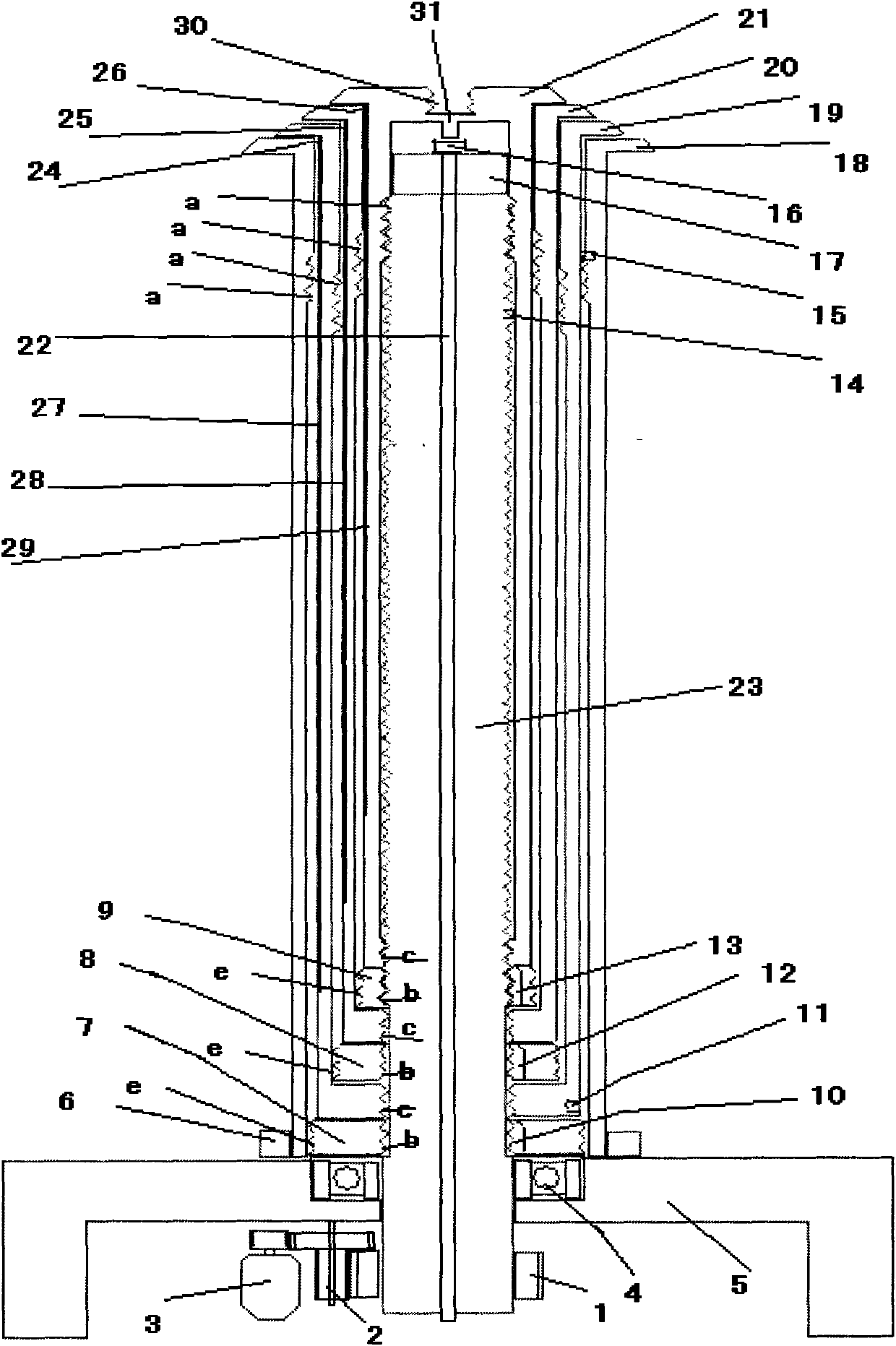

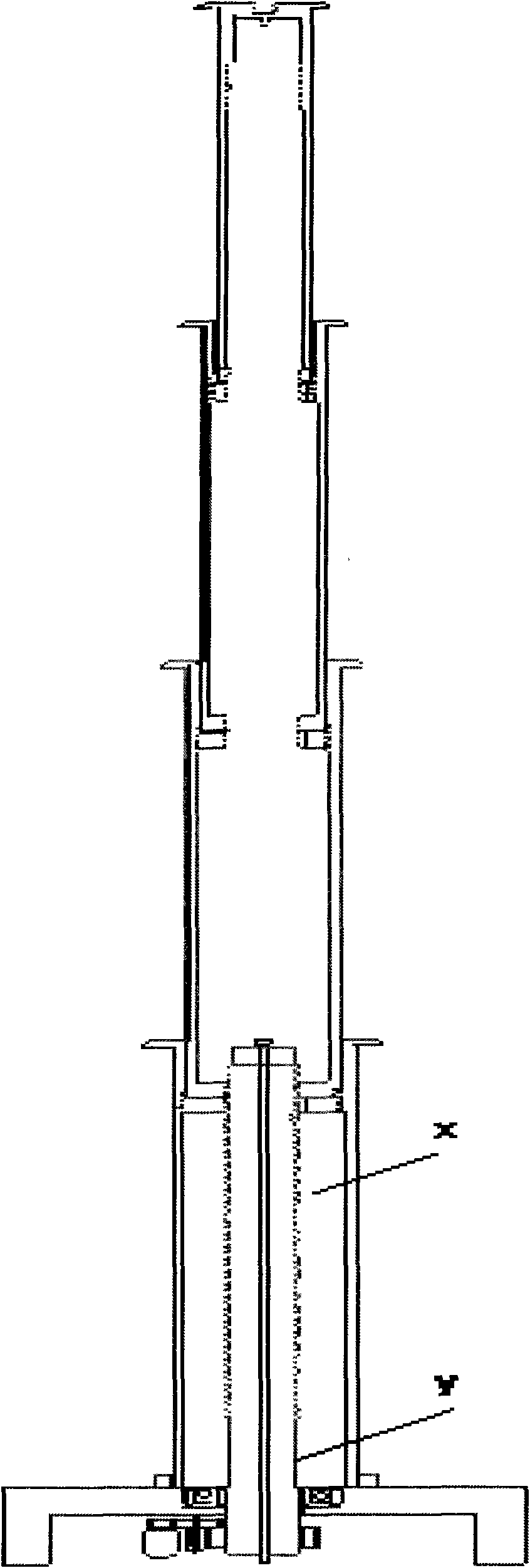

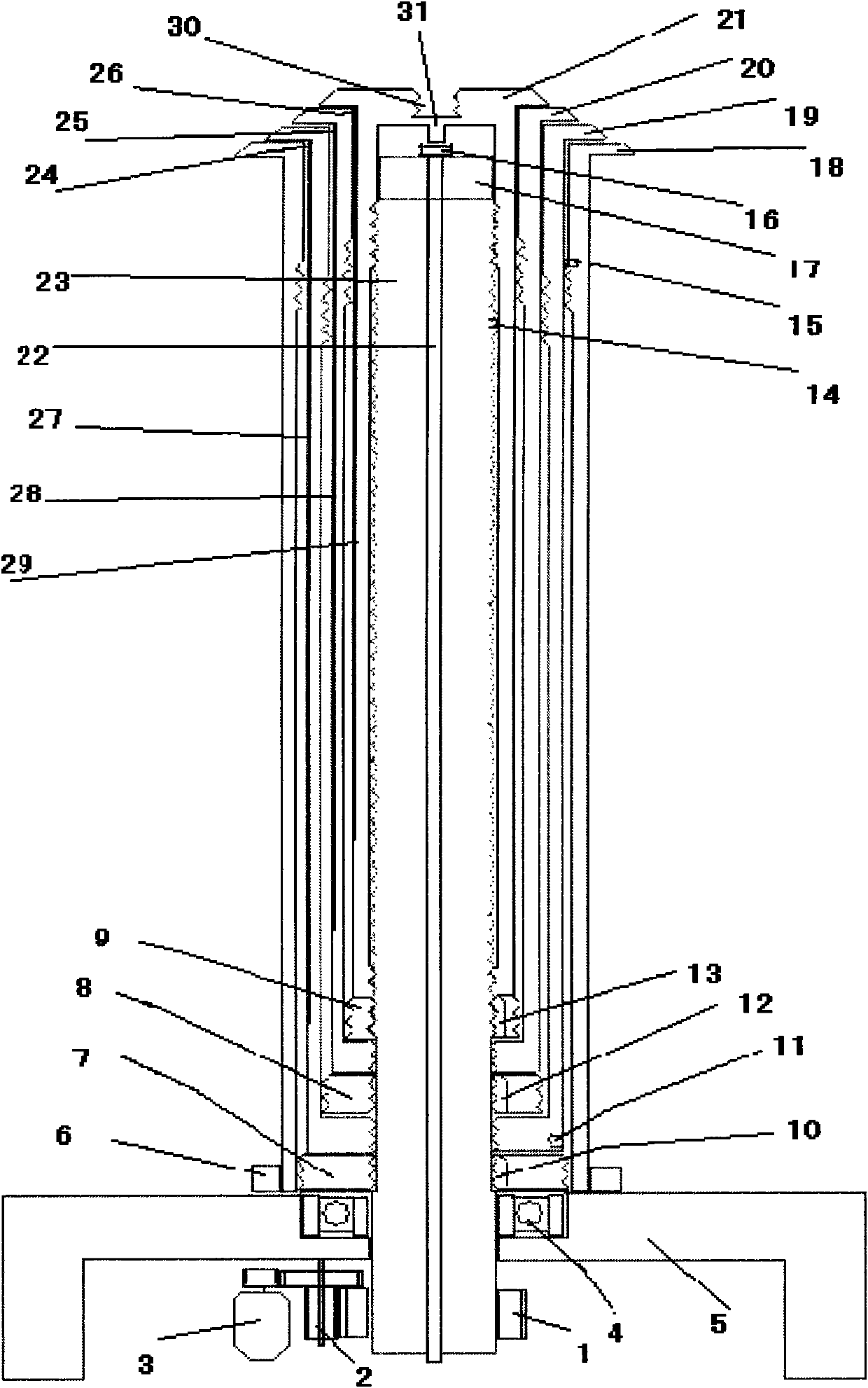

[0017] Figure 1 to Figure 2 Among them, there is a base 5 under the electric spiral lifting rod, and a bearing 4 is installed on the plane at the center of the base. Above the base, there are n circular lifting joint rods 18.19 whose axes are on the same line and whose diameters are sequentially nested together from large to small. .20.21 (this manual takes 4 lifting joints as an example, if there are n lifting joints, the working principle is exactly the same n=3-n.n>3), the inner upper part of each lifting joint has reverse thread a and lower thread c , the bottom of the lower thread is connected with a fastening nut 7.8.9, the outer thread e of the fastening nut is a reverse thread, and the inner thread b has a small card slot 10.12.13 perpendicular to it. There is a stop switch 15 above the inside of the penultimate lifting joint, and correspondingly there is a stop peak 11 below the outside of the penultimate lifting joint, and there is a stop and landing peak 31 above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com